Method for determining residual selenium dioxide content in sodium selenite

A technology of sodium selenite and a determination method, which is applied in the direction of chemical analysis by titration, can solve the problems of low selenium dioxide and the inability to measure the content of selenium dioxide, and achieve the effect of reliable guarantee and convenient determination method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

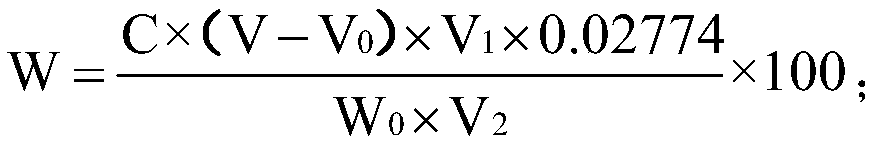

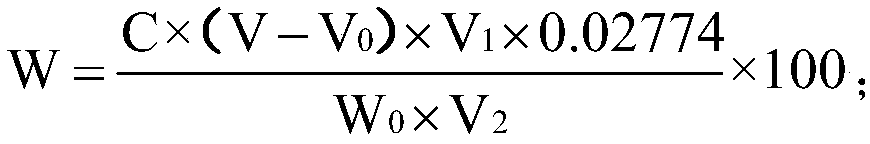

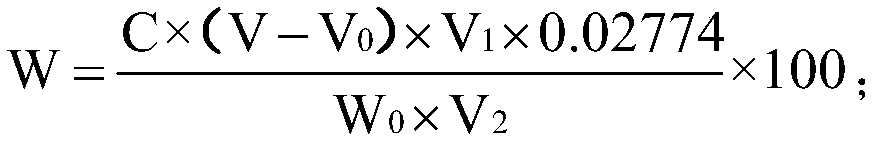

[0040] A kind of assay method of residual selenium dioxide content in sodium selenite of the present invention, comprises the following steps:

[0041] (1) take by weighing sodium selenite sample quality W 0 =10.0012g (accurate to 0.0002g), put it in a beaker, add V 1 =100ml absolute ethanol, stirred for 1min, filtered after standing;

[0042] (2) Use a pipette to accurately pipette V 2 =50mL filtered solution in a 300mL iodine bottle, add 80mL of water, add 5mL of (1+1) hydrochloric acid solution with a mass concentration of 37%, add 2g of potassium iodide, cover the iodine bottle cap, shake well, and place in a dark place 10min;

[0043] (3) Titrate with a standard solution of sodium thiosulfate (accurate to 0.0001mol / L) with a calibrated concentration C=0.1005mol / L to the near end point, after the color changes from brownish red to light yellow, add 2mL of 10g / L starch indicator , continue to titrate to the end point, the color of the solution turns bright orange, the o...

Embodiment 2

[0049] A kind of assay method of residual selenium dioxide content in sodium selenite of the present invention, comprises the following steps:

[0050] (1) take by weighing sodium selenite sample quality W 0 =10.0007g (accurate to 0.0002g), put it in a beaker, add V 1 = 100ml of absolute ethanol, stirred for 1min, dried and filtered after standing;

[0051] (2) Use a pipette to accurately pipette V 2 =50mL filtered solution in a 300mL iodine bottle, add 80mL of water, add 5mL of (1+1) hydrochloric acid solution with a mass concentration of 37%, add 2g of potassium iodide, cover the iodine bottle cap, shake well, and place in a dark place 10min;

[0052] (3) Titrate with the calibrated concentration C = 0.1005mol / L sodium thiosulfate standard solution (accurate to 0.0001mol / L) to the near end point, after the color changes from brownish red to light yellow, add 2mL of 10g / L starch indicator, Continue to titrate to the end point, the color of the solution turns bright orange...

Embodiment 3

[0059] A kind of assay method of residual selenium dioxide content in sodium selenite of the present invention, comprises the following steps:

[0060] (1) take by weighing sodium selenite sample quality W 0 =10.0024g (accurate to 0.0002g), put it in a beaker, add V 1 = 100ml of absolute ethanol, stirred for 1min, dried and filtered after standing;

[0061] (2) Use a pipette to accurately pipette V 2 =50mL filtered solution in a 300mL iodine bottle, add 80mL of water, add 5mL of (1+1) hydrochloric acid solution with a mass concentration of 37%, add 2g of potassium iodide, cover the iodine bottle cap, shake well, and place in a dark place 10min;

[0062] (3) Titrate with the calibrated concentration C=0.1005mol / L sodium thiosulfate standard solution to the near end point, after the color changes from brownish red to light yellow, add 2mL of 10g / L starch indicator, continue titration to the end point, the solution color changes It is bright orange, the original color disappe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com