Manufacturing method and package structure of optical fiber stripper

A technology of packaging structure and manufacturing method, applied in the field of laser technology and optical fiber, can solve the problems of burnout of optical fiber stripper, damage of optical fiber stripper, leakage of laser light, etc., to increase absorption area and absorption efficiency, improve stability and Work efficiency and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

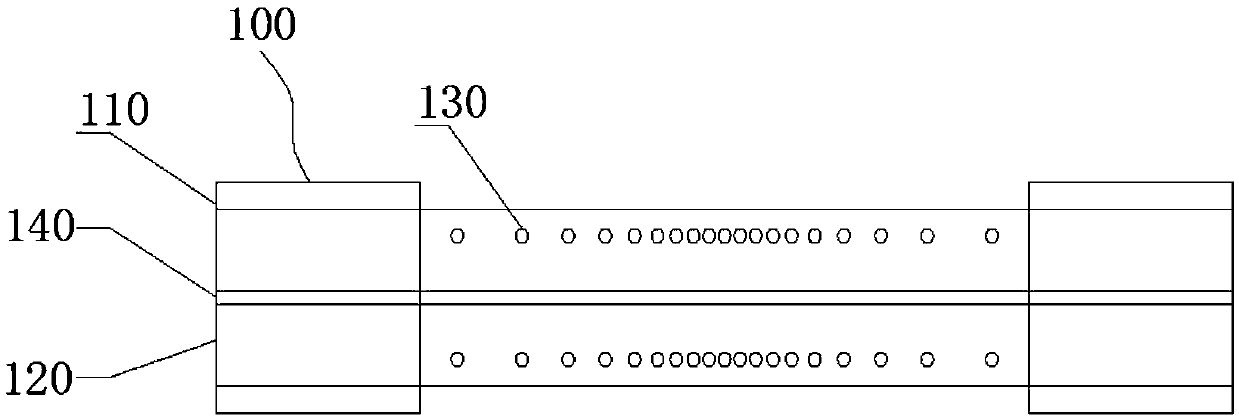

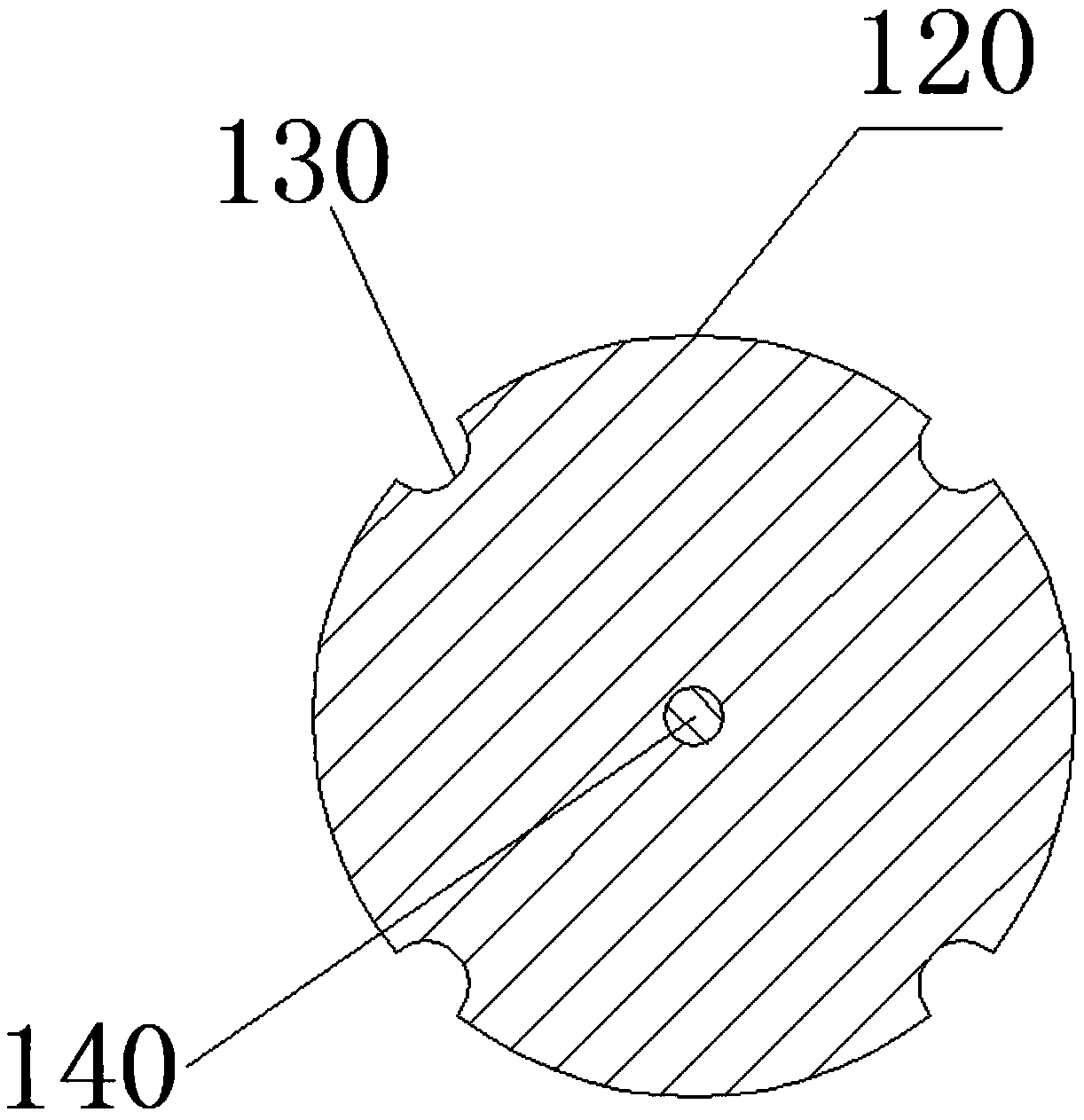

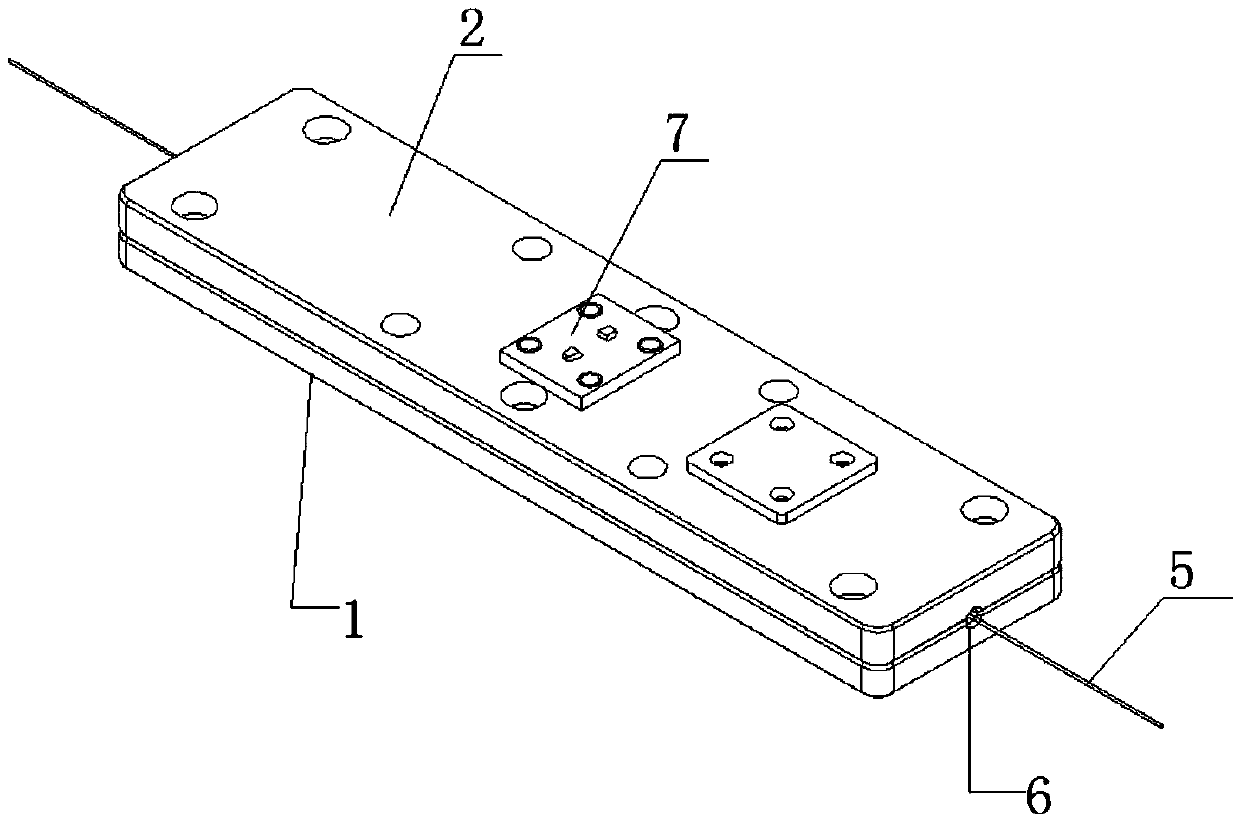

[0024] The manufacturing method of the optical fiber mode stripper of the present invention is to use a laser to etch the surface of the inner cladding 120 of the double-clad passive optical fiber 100 from which the outer cladding 110 has been stripped, and to form at least one row on the inner cladding of the double-clad passive optical fiber. For the plurality of holes 130 arranged at intervals along the axial direction, the etching density of the plurality of holes gradually decreases from the middle to both ends, and the etching depth of the plurality of holes gradually becomes shallower from the middle to both ends. In this way, by improving the manufacturing method of the traditional optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com