Quantum-dot light-emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as low carrier recombination efficiency, insufficient hole injection, and reduced quantum yield, to avoid quantum Yield drop, reduced quantum yield drop, effect of slowing down electron injection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

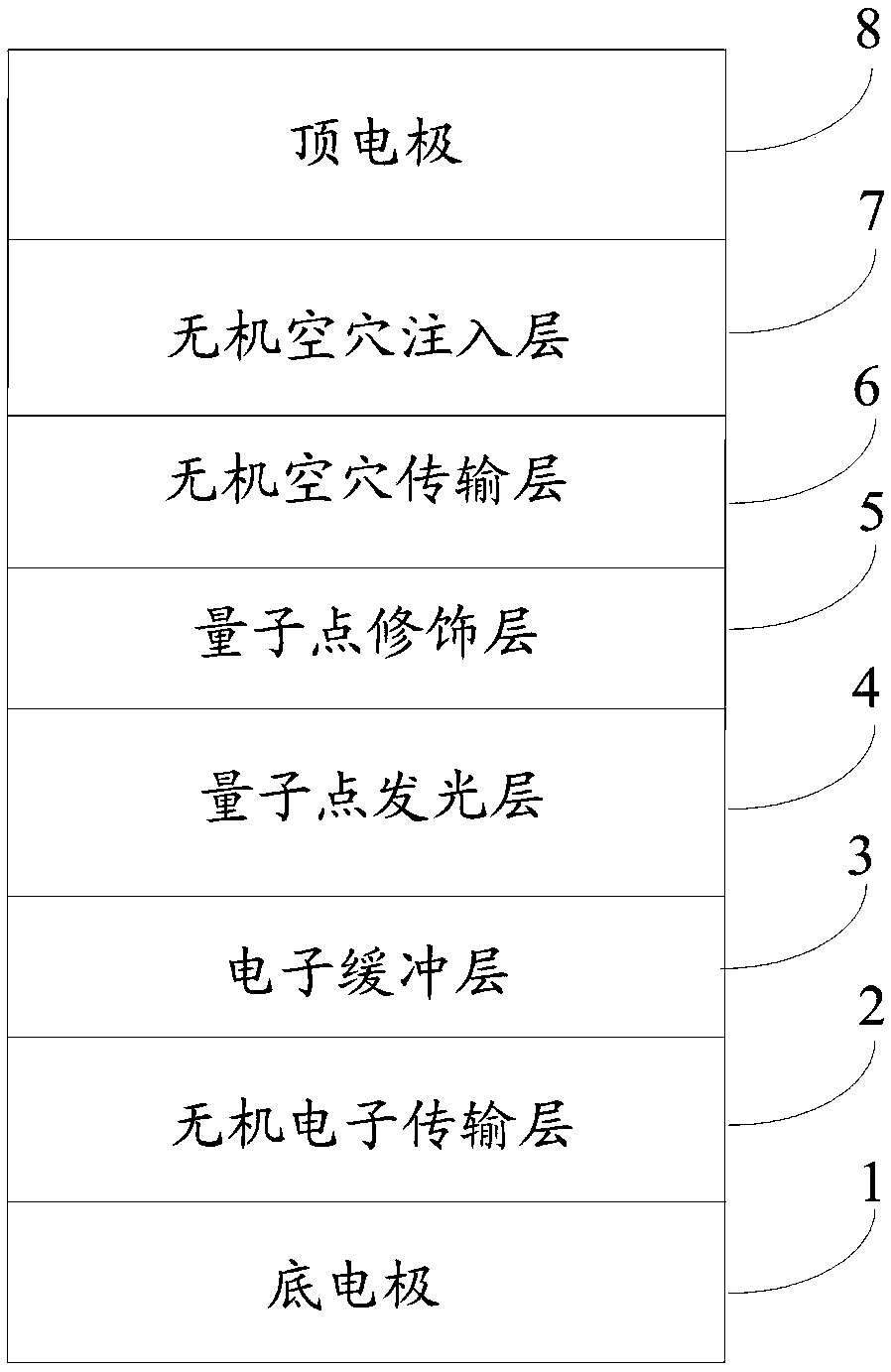

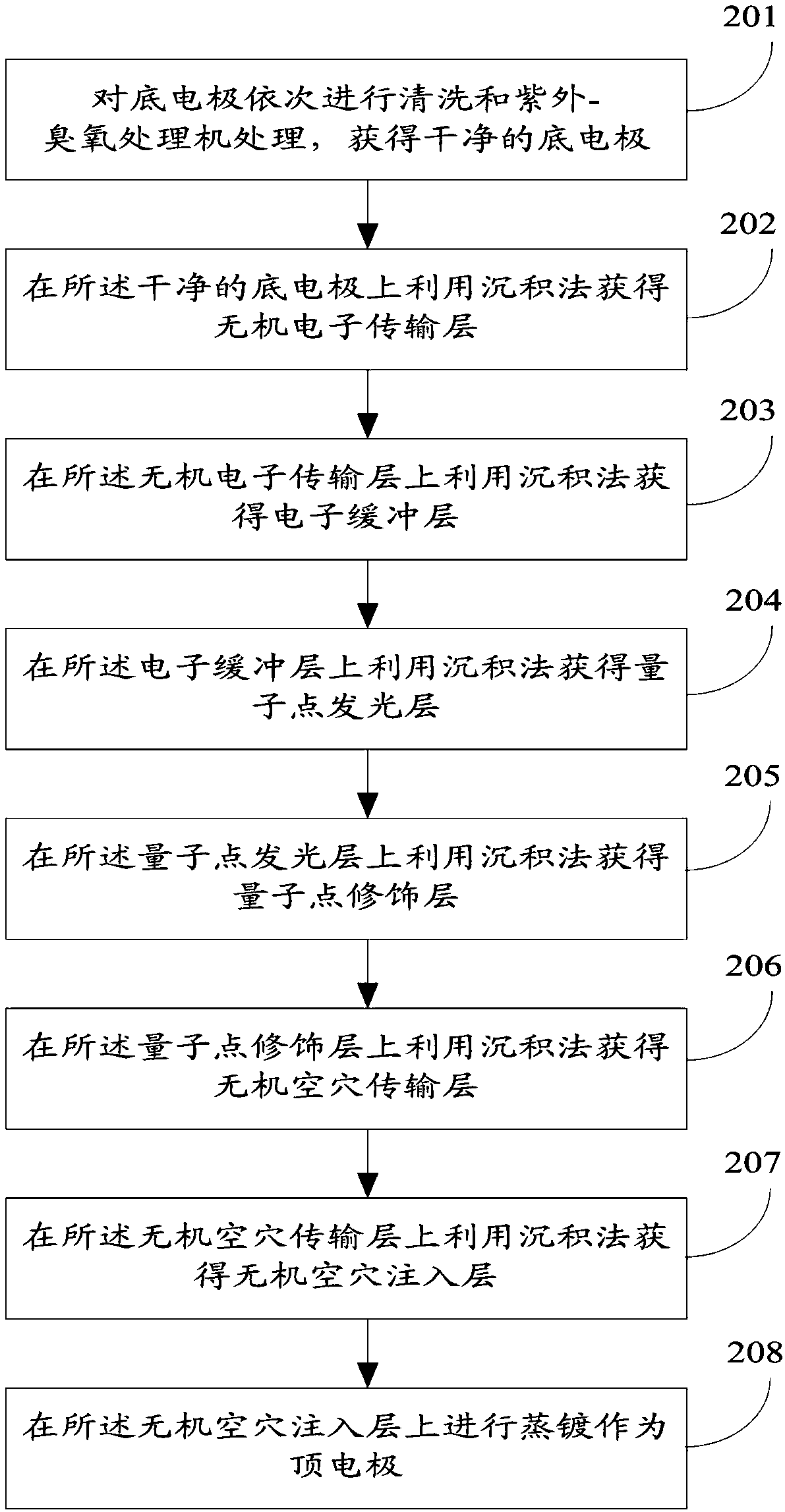

[0061] figure 2 It is a flow chart of the method for preparing quantum dot light-emitting diodes according to the embodiment of the present invention, such as figure 2 shown. The preparation method of quantum dot light-emitting diode specifically comprises the following steps:

[0062] Step 201: Cleaning the bottom electrode 1 and treating it with an ultraviolet-ozone processor in sequence to obtain a clean bottom electrode 1; specifically:

[0063] Clean the bottom electrode 1 of the glass or PET film substrate containing the ITO electrode with pure water, acetone and isopropanol for 10-30 minutes respectively.

[0064] Use ultraviolet-ozone treatment machine (UV / O to the bottom electrode 1 after cleaning) 3 ) for further cleaning for 10 to 30 minutes to obtain a clean bottom electrode 1 .

[0065] In the present invention, cleaning with pure water, acetone and isopropanol for the first time is to remove the particle impurities on the surface, and the second time uses t...

Embodiment 1

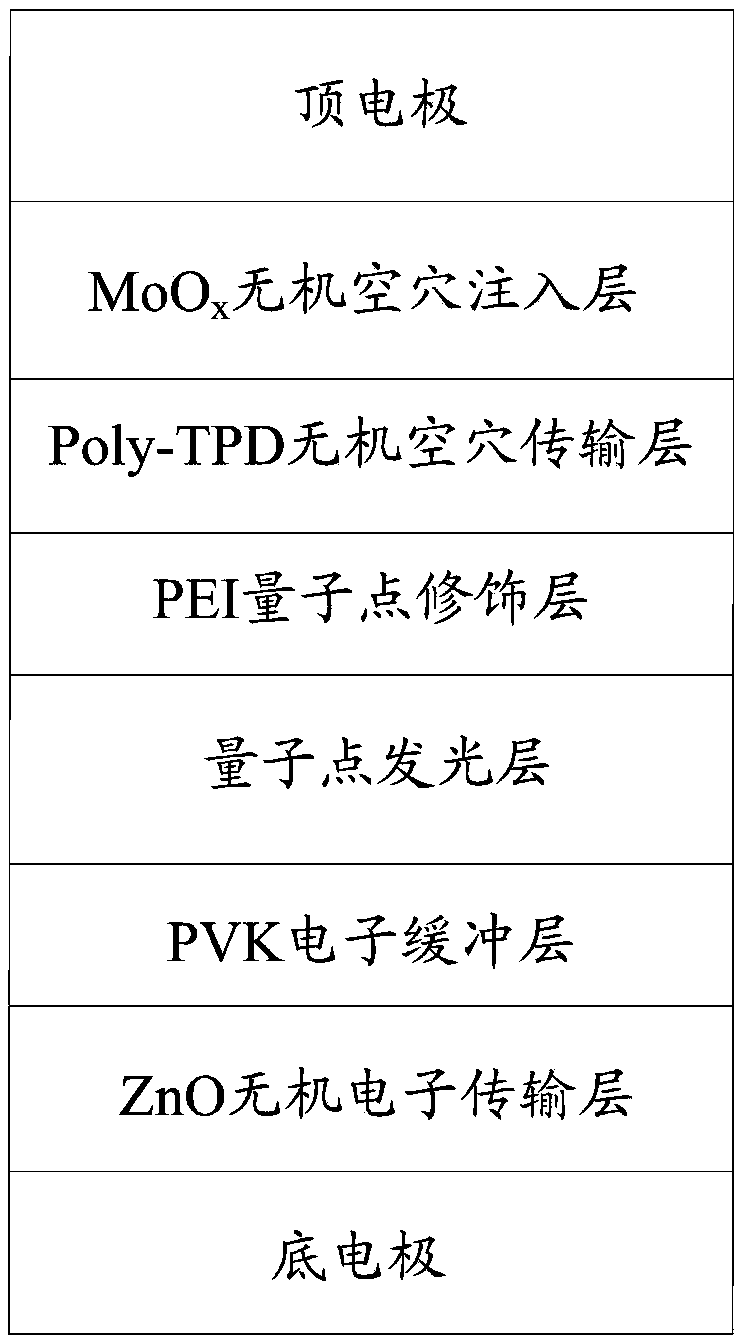

[0092] image 3 For the embodiment of the present invention, PVK is used as the electronic buffer layer 3, and PEI is used as the quantum dot light-emitting diode of the quantum dot modification layer 5, such as image 3 shown. A glass substrate with an ITO electrode was used as the bottom electrode 1, and the bottom electrode 1 was sequentially treated with pure water, acetone, isopropanol, and an ultraviolet-ozone processor (UV / O 3 ) treatment, each treatment for 15 minutes, to remove impurities and organic matter on the residual glass surface, and improve the work function of ITO; then use the spin coating method to prepare a 100nm thick ZnO thin film on the clean bottom electrode 1 containing the ITO electrode side As the inorganic electron transport layer 2 (ZnO dissolved in absolute ethanol, the solution concentration is 60 mg / ml, the spin coating speed is 2000 rpm, and the spin coating time is 60 seconds), the ZnO thin film is dried in a glove box at 60 °C 5min to rem...

Embodiment 2

[0094] Figure 5 For the embodiment of the present invention, TFB is used as the electronic buffer layer 3, and PEIE is used as the quantum dot light-emitting diode of the quantum dot modification layer 5, such as Figure 5 shown. A glass substrate with an ITO electrode was used as the bottom electrode 1, and the bottom electrode 1 was sequentially treated with pure water, acetone, isopropanol, and an ultraviolet-ozone processor (UV / O 3 ) treatment, each treatment for 15 minutes, to remove impurities and organic matter on the residual glass surface, and improve the work function of ITO; then utilize the spin coating method to prepare a 100nm thick ZnMgO thin film on the clean bottom electrode 1 containing the ITO electrode side As the inorganic electron transport layer 2 (ZnMgO dissolved in absolute ethanol, the solution concentration is 60 mg / ml, the spin coating speed is 2000 rpm, and the spin coating time is 60 seconds), the ZnMgO film is dried in a glove box at 60 °C 5mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com