Method for preparing hop whitening extract

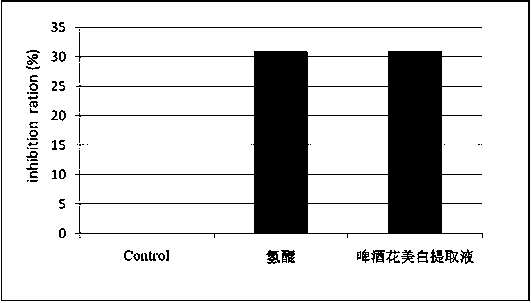

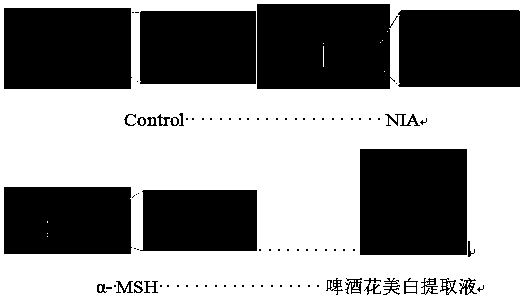

A technology for hops and extracts, applied in the field of preparation of hop whitening extracts, can solve the problems of not involving hops whitening functional components, not involving hops xanthohumol extract whitening functional components and efficacy verification, etc. The effect of inhibiting transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

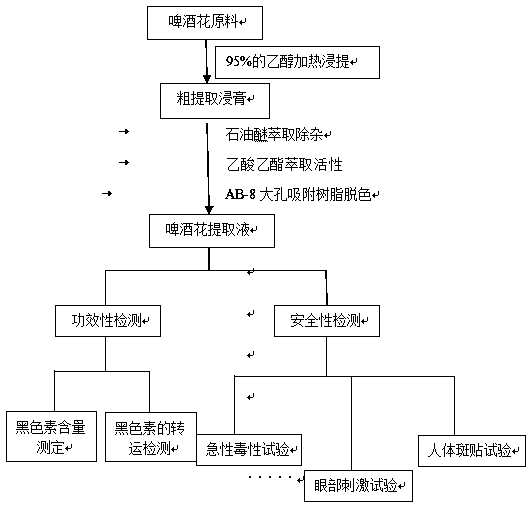

Method used

Image

Examples

Embodiment 1

[0035] Take 5 kg of hop raw material, crush it after removing impurities, pass through a 100-mesh sieve, add 50 L of 95% alcohol, heat to 60 ° C for extraction, filter, recover the filtrate, repeat three times, and the filtrate is concentrated under reduced pressure at 48 ° C to obtain total hops. Extract concentrated solution 1.92kg, reserve sample 181g, set aside. Add an appropriate amount of water to the concentrated solution to form a suspension, add 5L of petroleum ether for extraction, stir well, place it at room temperature for more than 6 hours, suck out the upper layer to obtain petroleum ether extract, and extract with petroleum ether three times to remove fat-soluble components; the lower layer of water Add 5L of ethyl acetate to the phase and extract continuously three times, combine the extracts, concentrate under reduced pressure at -0.09MPa and 48°C to recover the solvent, and obtain the crude extract of active components of hops, which is freeze-dried at -80°C t...

Embodiment 2

[0037]Take 1kg of hop raw material, remove impurities, crush, sieve, add 10L of 95% alcohol, heat to 55°C for extraction, filter, recover the filtrate, repeat three times, and concentrate the filtrate under reduced pressure at 50°C to obtain a crude extract for later use; Add an appropriate amount of water to the crude extract to form a suspension, then add 2L of petroleum ether to extract three times to remove fat-soluble components; add 2L of ethyl acetate to the lower aqueous phase for continuous extraction three times, combine the extracts, and store at -0.09MPa, 48°C Concentrate and recover the solvent under reduced pressure to obtain crude hop whitening extract extract, which is freeze-dried at -80°C to obtain hop whitening extract, a total of 320g; weigh 40g of crude extract, separate it with macroporous adsorption resin, collect 90% ethanol washing Dehydration, the flow rate is 20ml / min, the eluent is 3L, the eluent is concentrated under reduced pressure, and freeze-dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com