High-entropy alloy with high principal element single-phase close-packed hexagonal structure and preparation method thereof

A technology of hexagonal close-packed and high-entropy alloys is applied in the field of alloy materials, which can solve the problems of alloy structure research, less research on high-entropy alloys with close-packed hexagonal structure, and alloys staying in the initial development stage, so as to achieve the effect of expanding the research scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

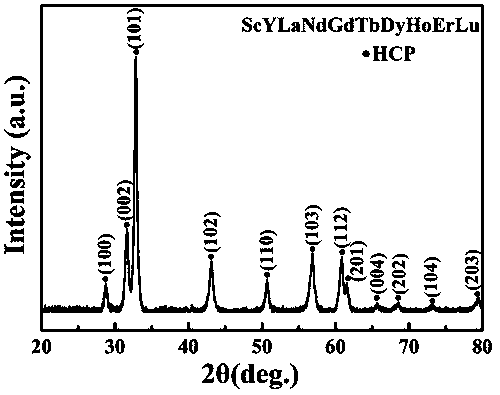

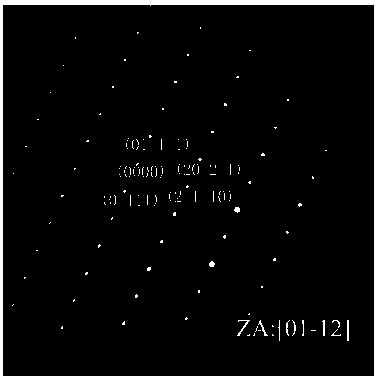

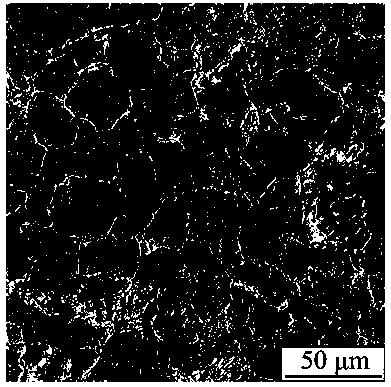

[0027] In this embodiment, rare earth elements with a purity of 99.99% are used as raw materials, and the composition is S 10 Y 10 La 10 Nd 10 Gd 10 Tb 10 Dy 10 Ho 10 Er 10 Lu 10 High-entropy alloys with a single-phase hexagonal close-packed structure.

[0028] The specific implementation process is as follows:

[0029] Step 1. Ingredients:

[0030]The molar ratio of each principal component in the alloy is converted into a mass ratio, and three parts are prepared respectively, and the total mass of each part is 10 grams. The purity of the elemental metal raw materials used in the experiment is as high as 99.99%. Polish the surface of each metal raw material to remove scale, cut the corresponding mass and put it into a beaker filled with alcohol, use an ultrasonic cleaner to remove impurities on the surface of the material, take out the metal after cleaning and dry it with a hair dryer; finally, use an electronic balance (accurate to 0.001g), repeated weighing 3 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com