Integrated contra-rotating double-rotor electric wheel integrated structure

An integrated technology of rotating dual-rotor electric wheels, which is applied in the field of integrated structure of integrated counter-rotating dual-rotor electric wheels, can solve the problems that it is difficult to meet the needs of vehicle operation, and the torque/power density of hub motors is high. Achieve the effects of improving system efficiency and operating stability, improving work efficiency and stability, and facilitating disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

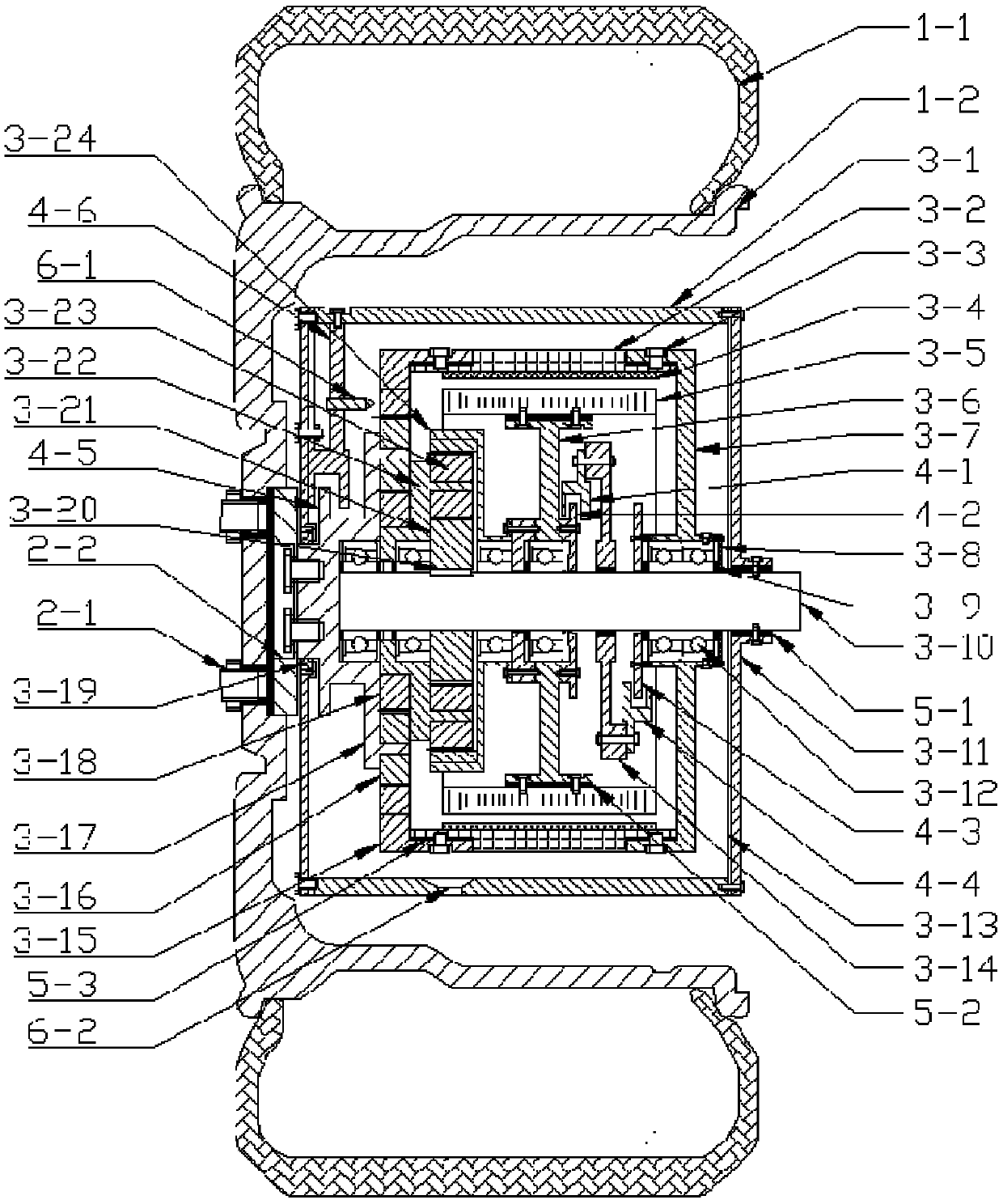

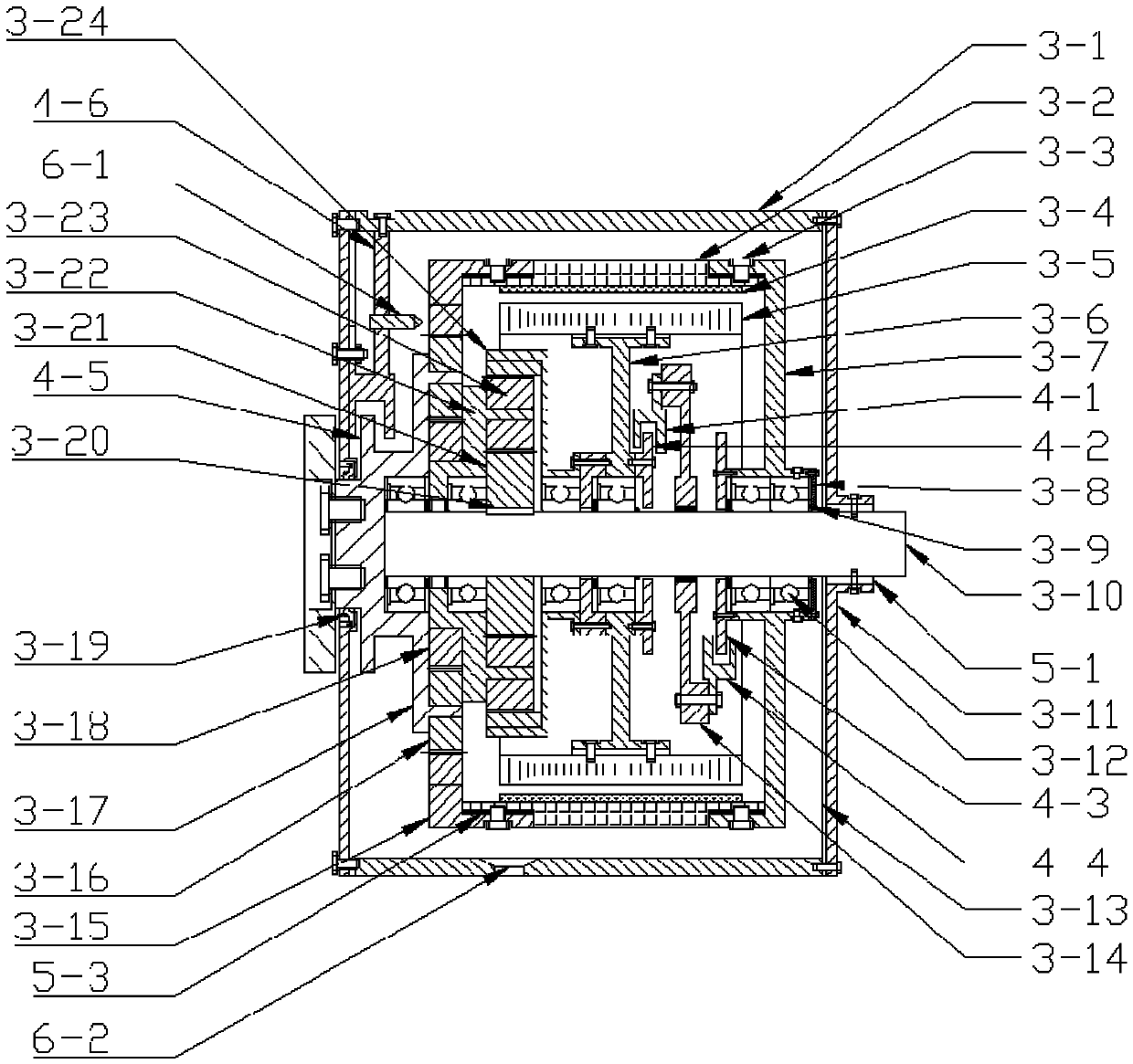

[0031] Figure 4 It is a structural principle diagram of Embodiment 1 of the present invention for vehicles. The structure and principle of embodiment 1 are as follows:

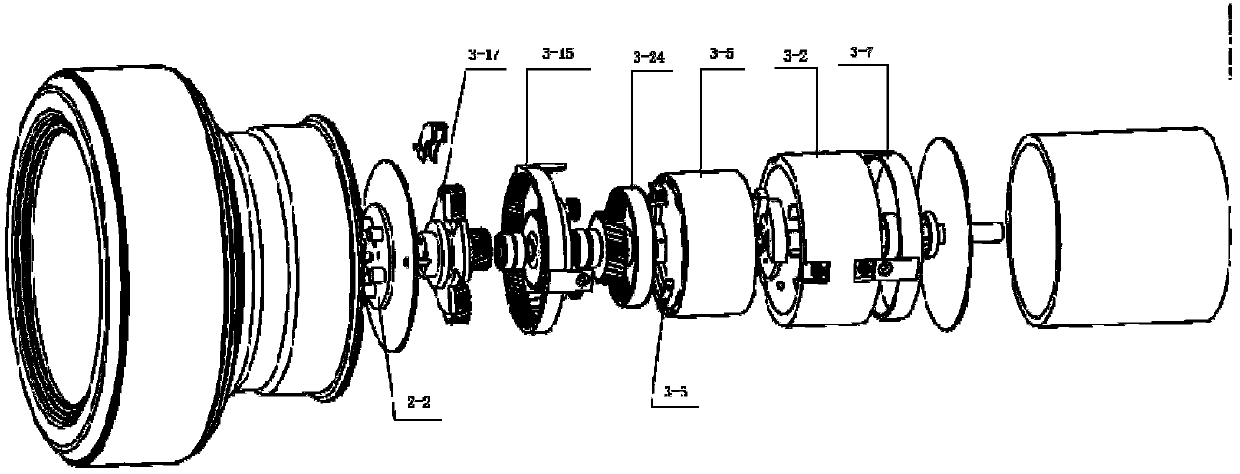

[0032] The inner rotor 3-5 is assembled on the fixed shaft 3-10 through the stator support 3-6, the rubber gasket 5-2 (acting as connection, support, and damping), the bearing 3-12 and bolts, etc., and the bearing 3-12 The left and right ends are equipped with end covers 4-2 for sealing and positioning. The left end cover is connected with the stator ring gear 3-24. The stator ring gear 3-24 is connected to the shaft 3-10 through the bearing 3-12 to rotate. The ring gear 3-24 Planetary gear 3-23, planet carrier 3-22, sun gear 3-21 are installed inside (the sun gear 3-21 is connected and fixed on the shaft 3-10 through the key 3-20), the right end cover 4-2 and the brake caliper 4 -1 Cooperate installation, the brake caliper 4-1 is installed on the brake bracket 3-14; the outer rotor 3-2 rotates on the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com