A compound inducer for in situ template-induced synthesis of nano-calcium carbonate and its application

A nano-calcium carbonate and inducer technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, nanotechnology, etc., can solve the problems of lack of development in refinement and functionalization, and excessive pursuit of miniaturization of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

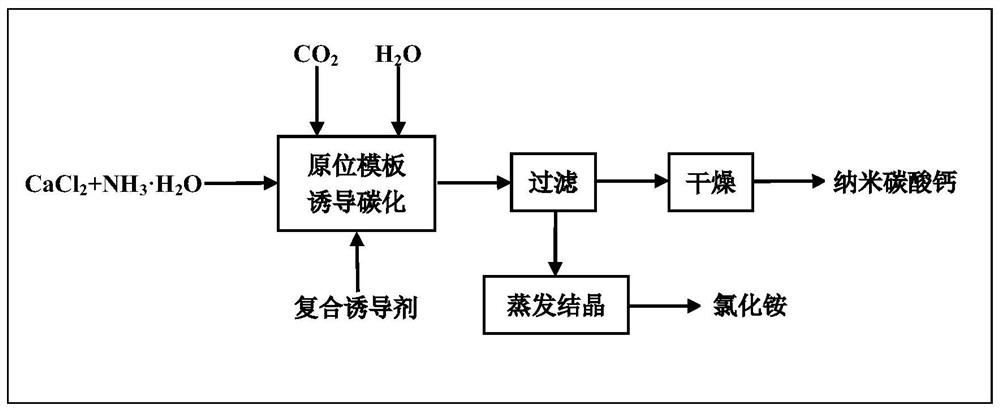

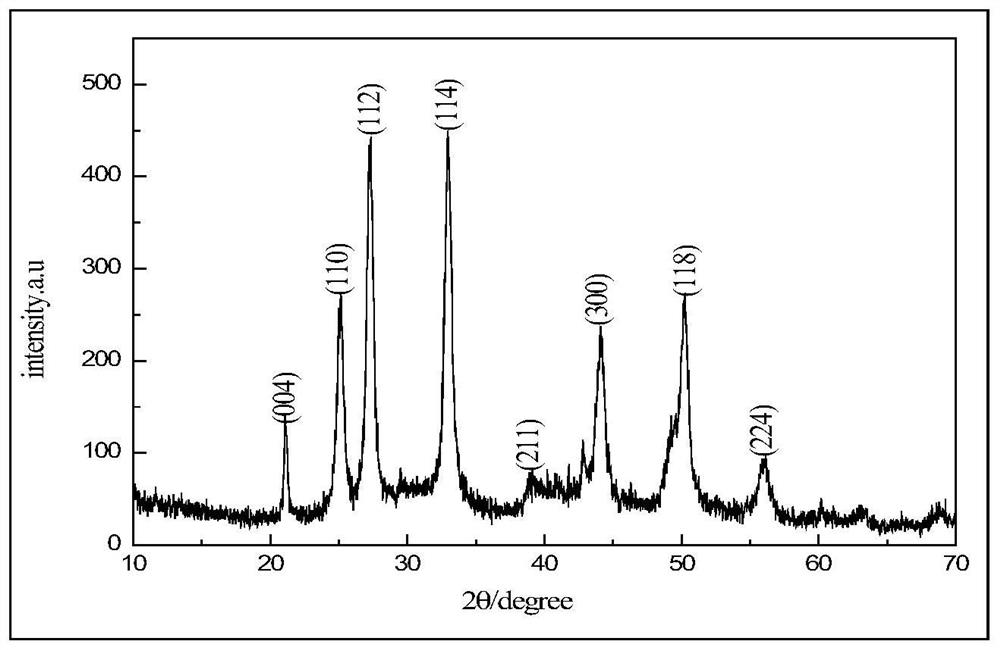

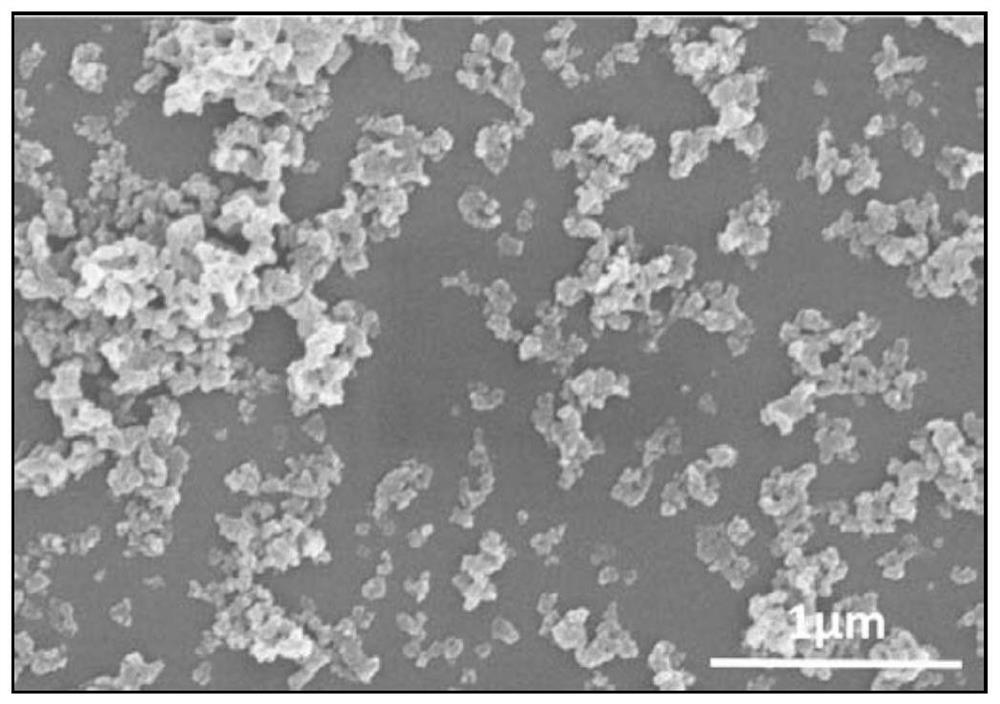

[0032] Take 10gCaCl 2 Add 10ml 25% concentrated ammonia water to 100ml water, then add 0.1g sodium D-gluconate, 0.12g polyethylene glycol and 0.25g sodium polyphosphate, mix well, stir at 15°C and introduce CO 2 , when the pH value of the solution reaches 8, the reaction is terminated, and the reaction solution is filtered to obtain the filtrate (NH 4 Cl solution), after evaporation, concentration and crystallization process, NH 4 Cl sample; the resulting filter cake was washed and dried to obtain nano-CaCO 3 sample. The prepared samples were tested to be pure-phase vaterite-type nano-CaCO 3 , The particle size is 40nm.

Embodiment 2

[0034] Take 15gCaCl 2 Add 20ml of 25% concentrated ammonia water to 100ml of water, then add 0.14g sodium D-gluconate, 0.2g polyethylene glycol and 0.35g sodium polyphosphate, mix well, stir at 20°C and introduce CO 2 , when the pH value of the solution reaches 7.5, the reaction is terminated, and the reaction solution is filtered to obtain the filtrate (NH 4 Cl solution), after evaporation, concentration and crystallization process, NH 4 Cl sample; the resulting filter cake was washed and dried to obtain nano-CaCO 3 sample. The prepared samples were tested to be pure-phase vaterite-type nano-CaCO 3 , The particle size is 55nm.

Embodiment 3

[0036] Take 10gCaCl 2 Add 25ml of 25% concentrated ammonia water to 100ml of water, then add 0.2g of sodium D-gluconate, 0.1g of polyethylene glycol and 0.3g of sodium polyphosphate, mix well, stir at 25°C and pass in CO 2 , when the pH value of the solution reaches 8.5, the reaction is terminated, and the reaction solution is filtered to obtain the filtrate (NH 4 Cl solution), after evaporation, concentration and crystallization process, NH 4 Cl sample; the resulting filter cake was washed and dried to obtain nano-CaCO 3 sample. The prepared samples were tested to be pure-phase vaterite-type nano-CaCO 3 , The particle size is 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com