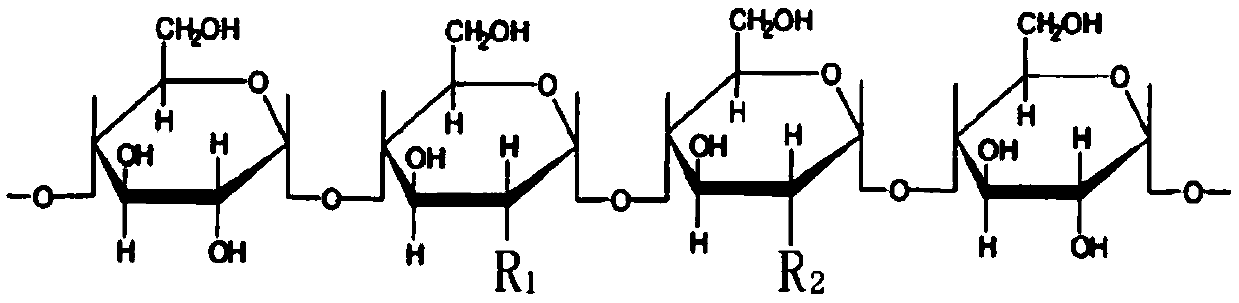

Quaternary ammonium salt cationic starch and preparation method thereof

A quaternary ammonium salt cation and starch technology, which is applied in the field of quaternary ammonium salt cationic starch and its preparation, can solve the problems of limited application field, limited degree of substitution, single variety, etc., and achieves controllable degree of substitution, simple method and excellent antibacterial performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

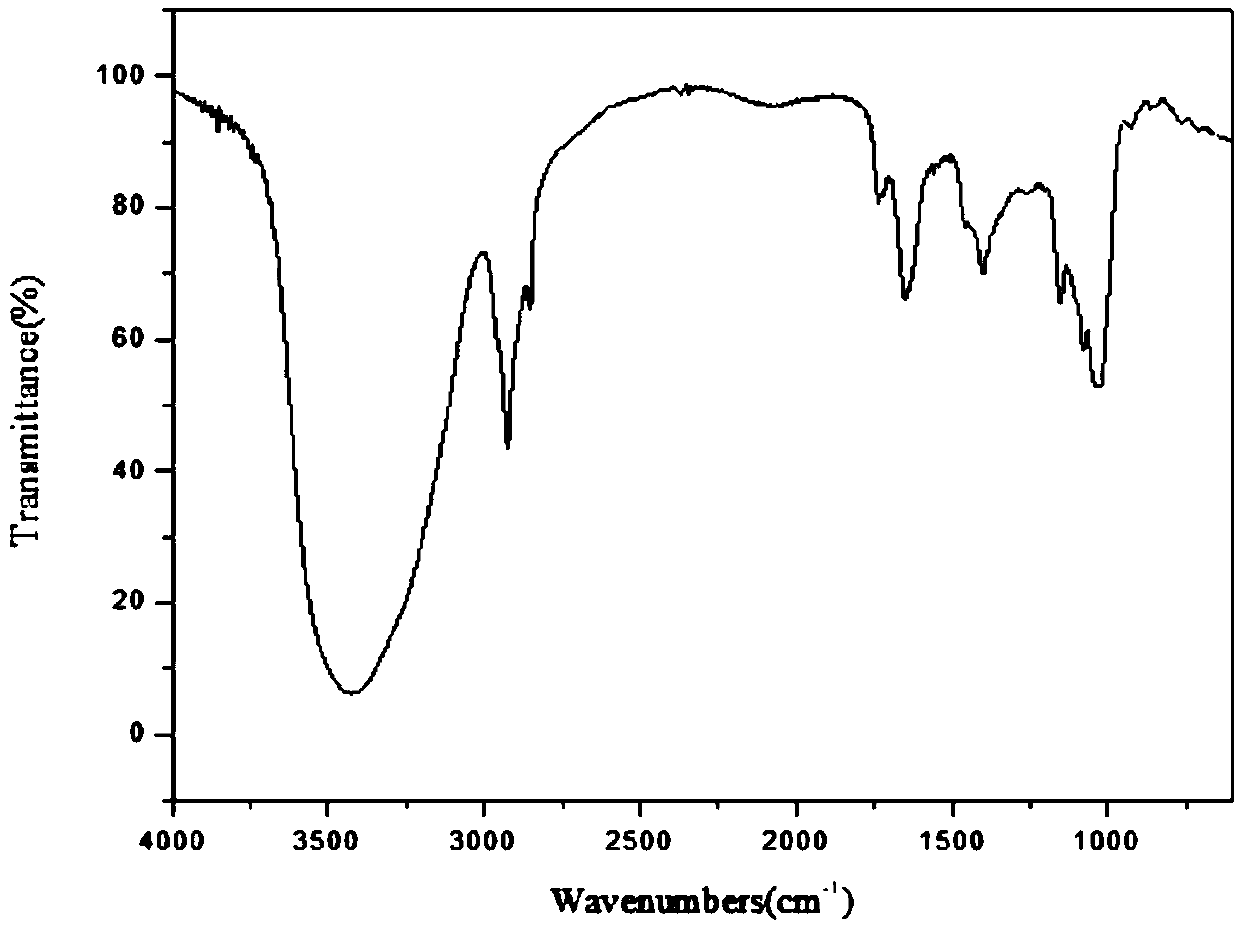

[0039] The preparation method of quaternary ammonium salt cationic starch of the present invention, the detailed steps of this preparation method are as follows:

[0040] a, first add 48.6g cornstarch and 100mL N,N-dimethylformamide solvent to the 250mL four-necked flask of the reaction vessel and stir (the whole process will keep the good stirring state that the materials are evenly mixed), heating, when the temperature Raise to 80°C, add 16.9g of 4-chlorobutyryl chloride dropwise, and finish dropping in 5 minutes. After dropping, keep the temperature of the reaction system at 80°C, and the reaction time under this temperature condition is 4h;

[0041] b. Then add 14.5g of triethylamine dropwise and finish dropping in 2 minutes. Control the temperature of the reaction system to be 80°C and the reaction time to be 6h;

[0042]c. After the reaction, the obtained reaction mixture was precipitated in ethanol, filtered with suction after the precipitation, washed twice with ethano...

Embodiment 2

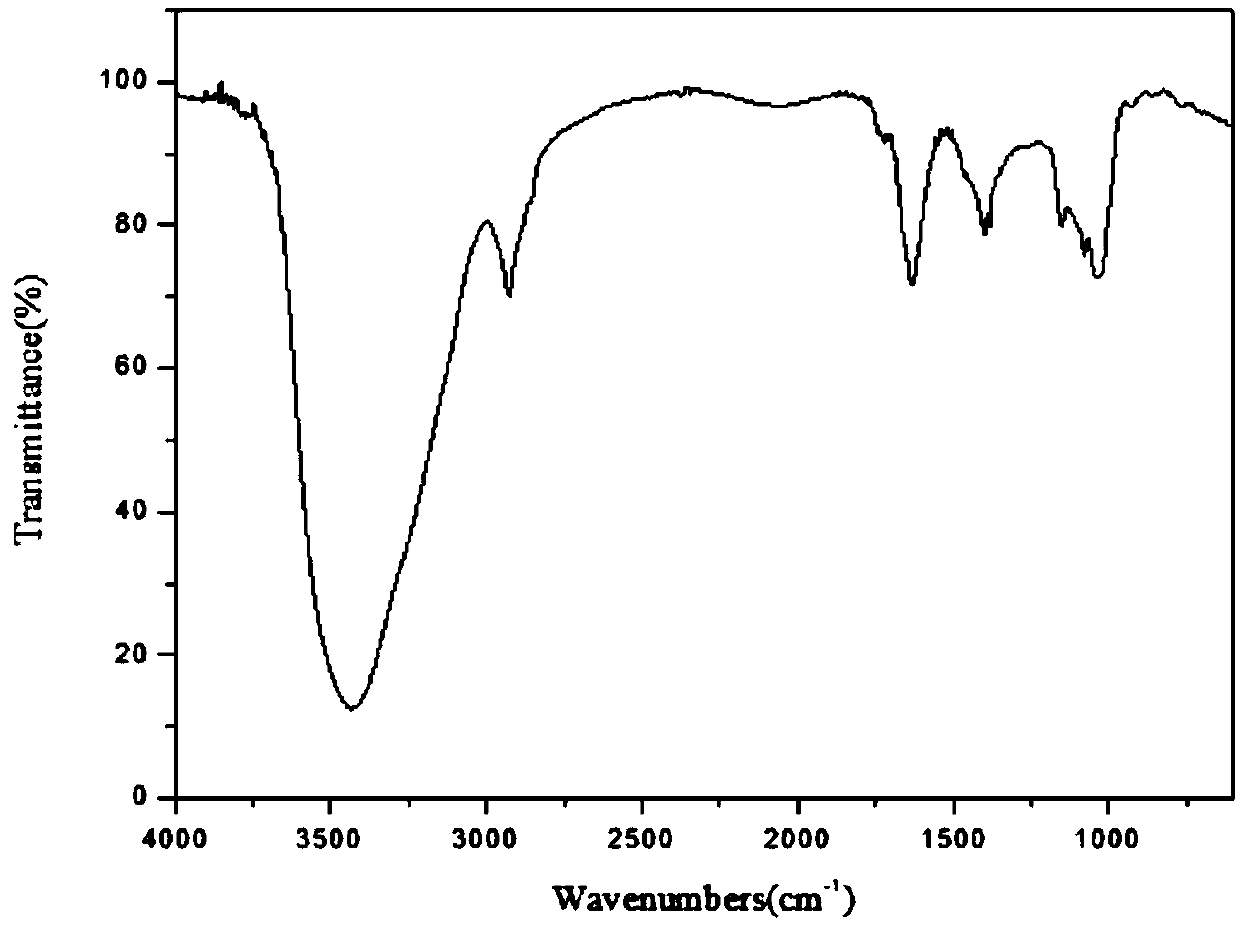

[0046] The preparation method of quaternary ammonium salt cationic starch of the present invention, the detailed steps of this preparation method are as follows:

[0047] a, first add 50.0g tapioca starch and 100mL N,N-dimethylformamide solvent to the reaction vessel 250mL four-necked flask and stir (the whole process will keep the good stirring state of the uniform mixing of materials), heating, when the temperature Raise to 80°C, add 14.1g of 4-chlorobutyryl chloride dropwise, and finish dropping in 5 minutes. After dropping, keep the temperature of the reaction system at 80°C, and the reaction time under this temperature condition is 4h;

[0048] b. Then add 12.1 g of triethylamine dropwise, and finish dropping in 2 minutes. Control the temperature of the reaction system at 80° C., and the reaction time is 8 hours;

[0049] c. After the reaction, the obtained reaction mixture was precipitated in ethanol, filtered with suction after the precipitation, washed twice with ethan...

Embodiment 3

[0053] The preparation method of quaternary ammonium salt cationic starch of the present invention, the detailed steps of this preparation method are as follows:

[0054] a, first add 50.0g sweet potato starch and 100mL N,N-dimethylformamide solvent to the 250mL four-necked flask of the reaction vessel and stir (the whole process will keep the good stirring state that the materials are evenly mixed), heating, when the temperature Raise to 70°C, add 11.2g of chloroacetyl chloride dropwise, and finish dropping in 5 minutes. After dropping, keep the temperature of the reaction system at 70°C, and the reaction time under this temperature condition is 6h;

[0055] b. Then add 17.4g of octyl dimethyl tertiary amine dropwise, and finish dropping in 2 minutes. The temperature of the reaction system is controlled at 100° C., and the reaction time is 8 hours;

[0056] c. After the reaction, the resulting reaction mixture was precipitated in methanol, filtered with suction after the prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com