2MgO.B2O3.H2O/RGO nano-composite flame retardant

A composite flame retardant, 2·6H2O technology, applied in the field of flame retardant, can solve the problems of material mechanical properties reduction, etc., and achieve the effect of improved mechanical properties, good flame retardant effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 3.71g (14mmol) Mg(NO 3 ) 2 ·6H 2 O, 1.73g (28mmol) H 3 BO 3 , 1.60g (40mmol) NaOH and 0.1g GO were added to 10mL deionized water, and ultrasonically dispersed at room temperature for 30 minutes at a power of 100W and a frequency of 60kHz with an ultrasonic cleaner, and then transferred to a PTFE-lined container with a volume of 50mL. In a stainless steel reaction kettle, put the reaction kettle in an oven at 240°C for 24 hours, take out the reaction kettle, and cool it to room temperature naturally in the air. °C for 12 hours to obtain 2MgO·B 2 o 3 ·H 2 O / RGO nanocomposite flame retardant.

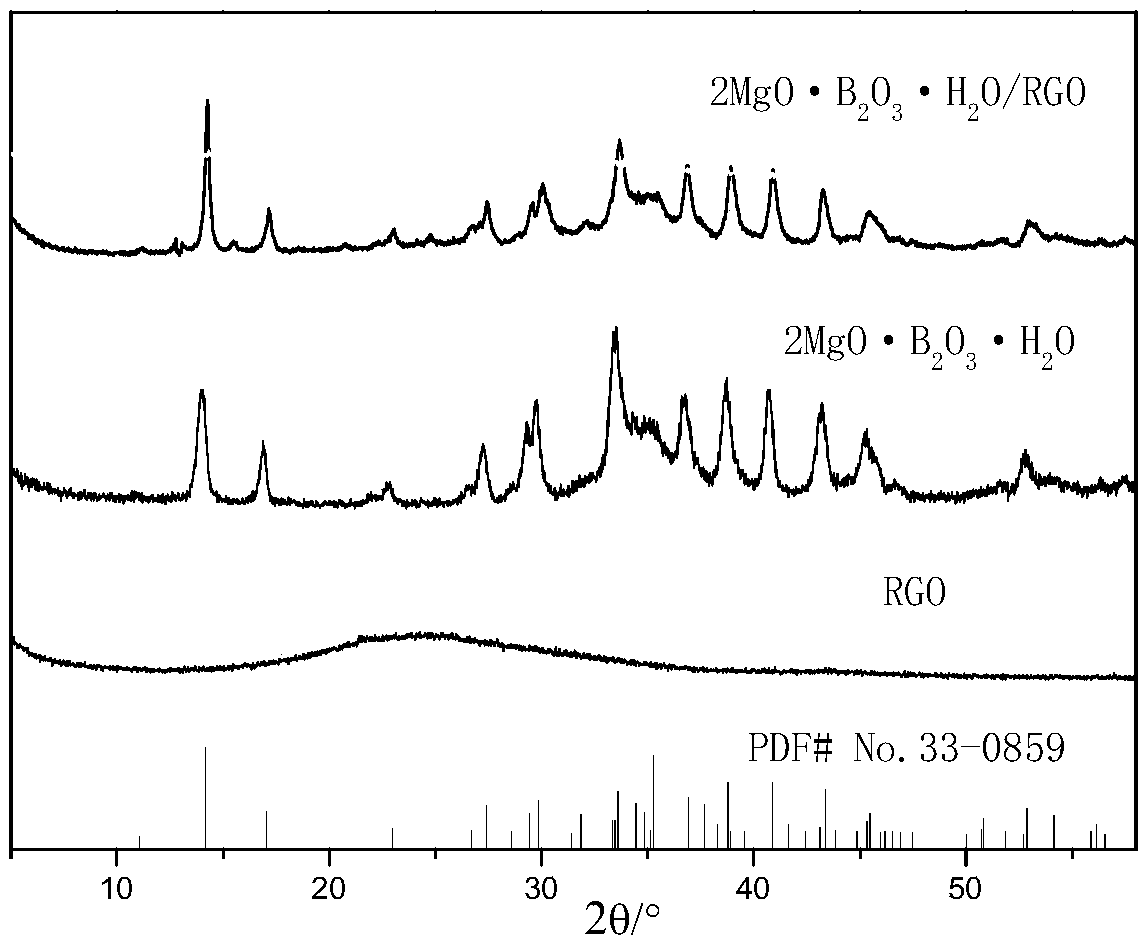

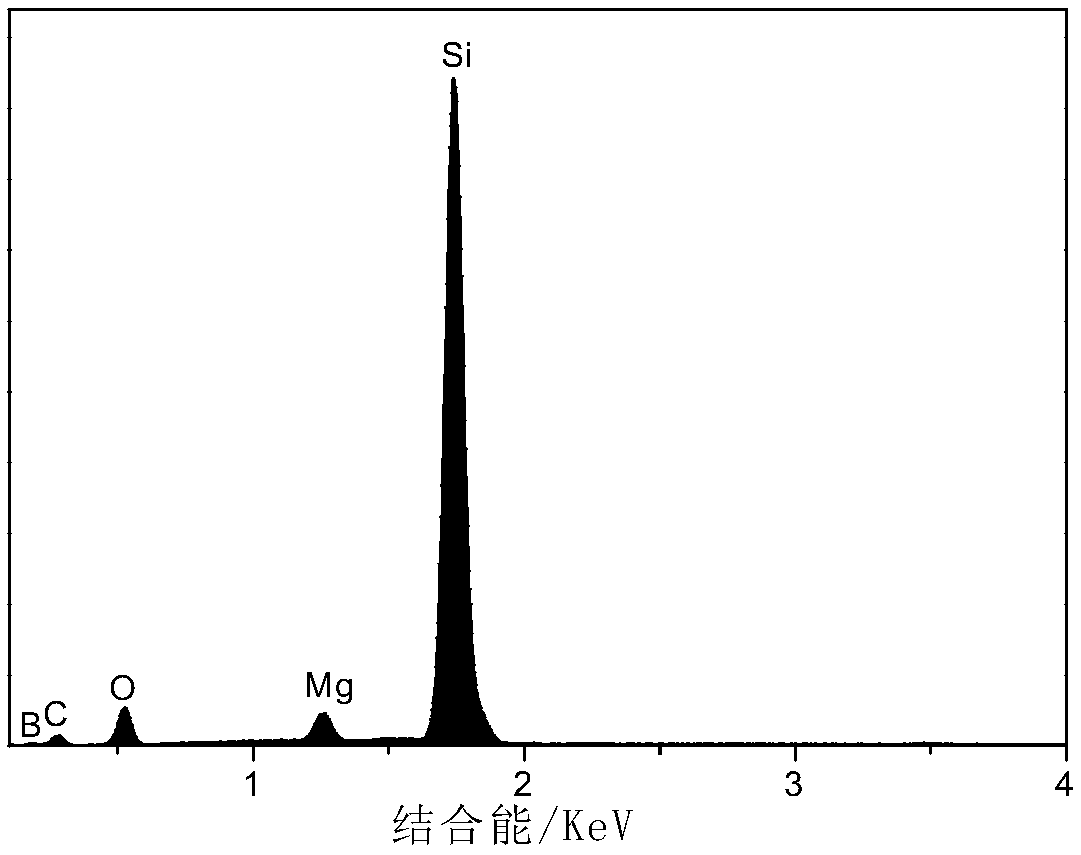

[0027] The inventor adopts X-ray diffractometer, scanning electron microscope and transmission electron microscope to carry out structure and morphology characterization to the sample obtained in embodiment 1 respectively, and the results are shown in Figure 1~4 . Depend on figure 1 It can be seen that the XRD pattern of the sample contains 2MgO·B 2 o 3 ·H 2 Diffractio...

Embodiment 2

[0032] 3.71g (14mmol) Mg(NO 3 ) 2 ·6H 2 O, 1.73g (28mmol) H 3 BO 3 , 1.60g (40mmol) NaOH and 0.1g GO were added to 10mL deionized water, and ultrasonically dispersed at room temperature for 30 minutes at a power of 100W and a frequency of 60kHz with an ultrasonic cleaner, and then transferred to a PTFE-lined container with a volume of 50mL. In a stainless steel reaction kettle, put the reaction kettle in an oven at 200°C for 18 hours, take out the reaction kettle, and cool it to room temperature naturally in the air. °C for 12 hours to obtain 2MgO·B 2 o 3 ·H 2 O / RGO nanocomposite flame retardant. Depend on Figure 6 and Figure 7 It can be seen that the obtained sample can be assigned as 2MgO·B 2 o 3 ·H 2 The complex of O and RGO.

Embodiment 3

[0034] 3.71g (14mmol) Mg(NO 3 ) 2 ·6H 2 O, 1.20g (19mmol) H 3 BO 3 , 0.95g (24mmol) NaOH and 0.2g GO were added to 10mL deionized water, and ultrasonically dispersed at room temperature for 30 minutes at a power of 100W and a frequency of 60kHz with an ultrasonic cleaner, and then transferred to a PTFE-lined container with a volume of 50mL. In a stainless steel reaction kettle, put the reaction kettle in an oven at 240°C for 24 hours, take out the reaction kettle, and cool it to room temperature naturally in the air. °C for 12 hours to obtain 2MgO·B 2 o 3 ·H 2 O / RGO nanocomposite flame retardant. Depend on Figure 8 and Figure 9 It can be seen that the obtained sample can be assigned as 2MgO·B 2 o 3 ·H 2 The complex of O and RGO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com