A kind of preparation method of oily dispersible modified graphene powder

A graphene powder and dispersion technology, applied in chemical instruments and methods, dyeing polymer organic compound treatment, fibrous fillers, etc., can solve the problems of poor dispersion and stability of graphene, complicated process, high cost, etc., and achieve repeatability High, mature and stable process, stable dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step, the preparation of PVP-GO water dispersion solution:

[0029] Take the graphene oxide aqueous solution in a 250ml beaker, adjust the pH value to 8, then blend and ultrasonically disperse PVP (K=12~30) for 10 minutes and let it stand for a while (the mass ratio of GO:PVP is 2:3).

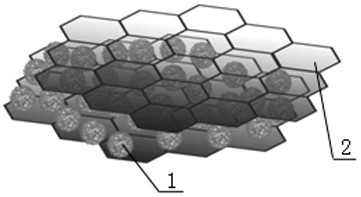

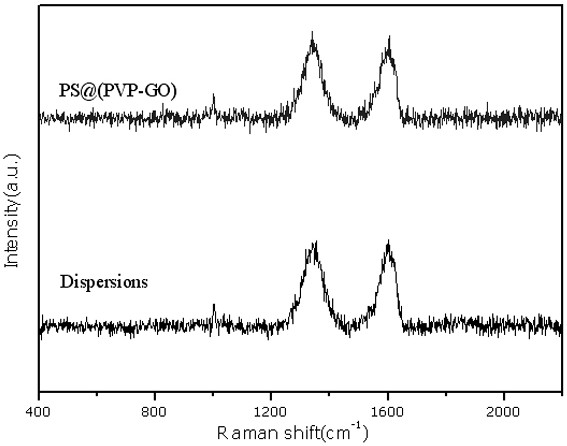

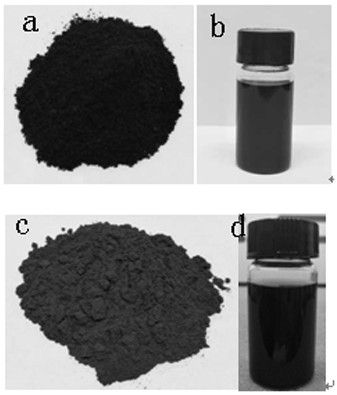

[0030] The second step, the preparation of polymer microspheres @ (PVP-rGO) powder:

[0031] Transfer the PVP-GO solution to a 250ml three-neck flask, weigh styrene (St) or methyl methacrylate (MMA), initiator (mass ratio K 2 S 2 o 8 :NaHSO 3 =1:1), feed into the three-neck flask at one time; pass N 2 Or protected by argon and placed in a 70°C water bath for 5 hours; then heated up to 90°C for condensing and reflux reduction with hydrazine hydrate for 2 hours, the solution gradually turned gray black, and the reduction product was filtered through filter paper (or high-speed centrifugation 8000~12000r / min ) to remove unloaded polymer microspheres, and then dry them in a va...

Embodiment 2

[0034] The adjustment of pH value 8 in the first step in Example 1 was changed to use 5% NaOH solution to wash the styrene monomer. All the other processes are as described in Example 1.

Embodiment 3

[0036] The mass ratio K described in the second step 2 S 2 o 8 :NaHSO 3 =1:1 is changed to 1:1~3, and all the other processes are as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com