A kind of desulfurization desiccant and preparation method thereof

A desiccant and desiccant removal technology, which is applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of zeolite molecular sieve application limitations, complex preparation process, and desiccant failure, and achieve simple and feasible solid-liquid separation steps , The recycling process is simple and the effect of reducing the cost of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

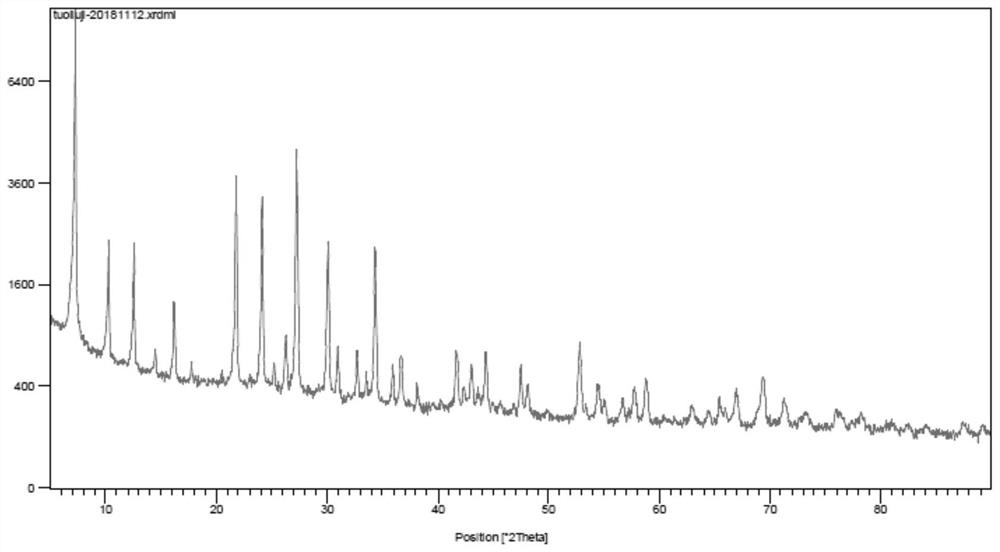

Image

Examples

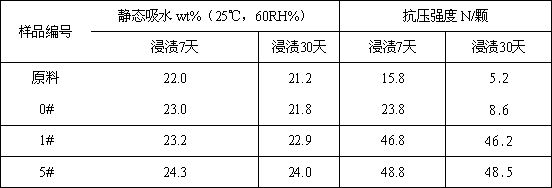

Embodiment 1

[0027] Preparation of a desulfurization desiccant: Use 6% NaOH solution to carry out alkali treatment on the formed 4A molecular sieve: keep it at 65°C~95°C for 4 hours, filter and wash it before use; according to the proportion of the metal salt component in the calcium chloride solution 0.5~8%, take 0.03mol / L.LaCl 3 Mix with 1.2mol / L calcium chloride in proportion; take 100g pretreated 4A strip molecular sieve, add to 300g containing 0.03mol / L.LaCl 3 In a mixed solution of 1.2mol / L calcium chloride, stirred and reacted at 85°C for 3h, after solid-liquid separation and washing, dried in an oven at 105°C for 3 hours, and then roasted in a muffle furnace at 500°C for 1h to obtain desulfurization Desiccant, recorded as 1# product.

Embodiment 2

[0029] With 0.03mol / LLaCl in embodiment 1 3 Replaced with 0.045mol / L ZnCl 2 Solution, other steps are with embodiment 1, and gained product is recorded as 2# product.

Embodiment 3

[0031] With 0.03mol / L LaCl in embodiment 1 3 Replaced with 0.02mol / L PdCl 2 Solution, other steps are with embodiment 1, and gained product is recorded as 3# product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com