Process for continuously separating antimony from gold in antimony-gold concentrate

A technology of antimony-gold and gold concentrates in mines, which is applied in the field of non-ferrous metallurgy, can solve the problems of complicated processes, limited development, increased operating costs, etc., achieve good gas fluidity, eliminate "thickness, no dead angle" Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

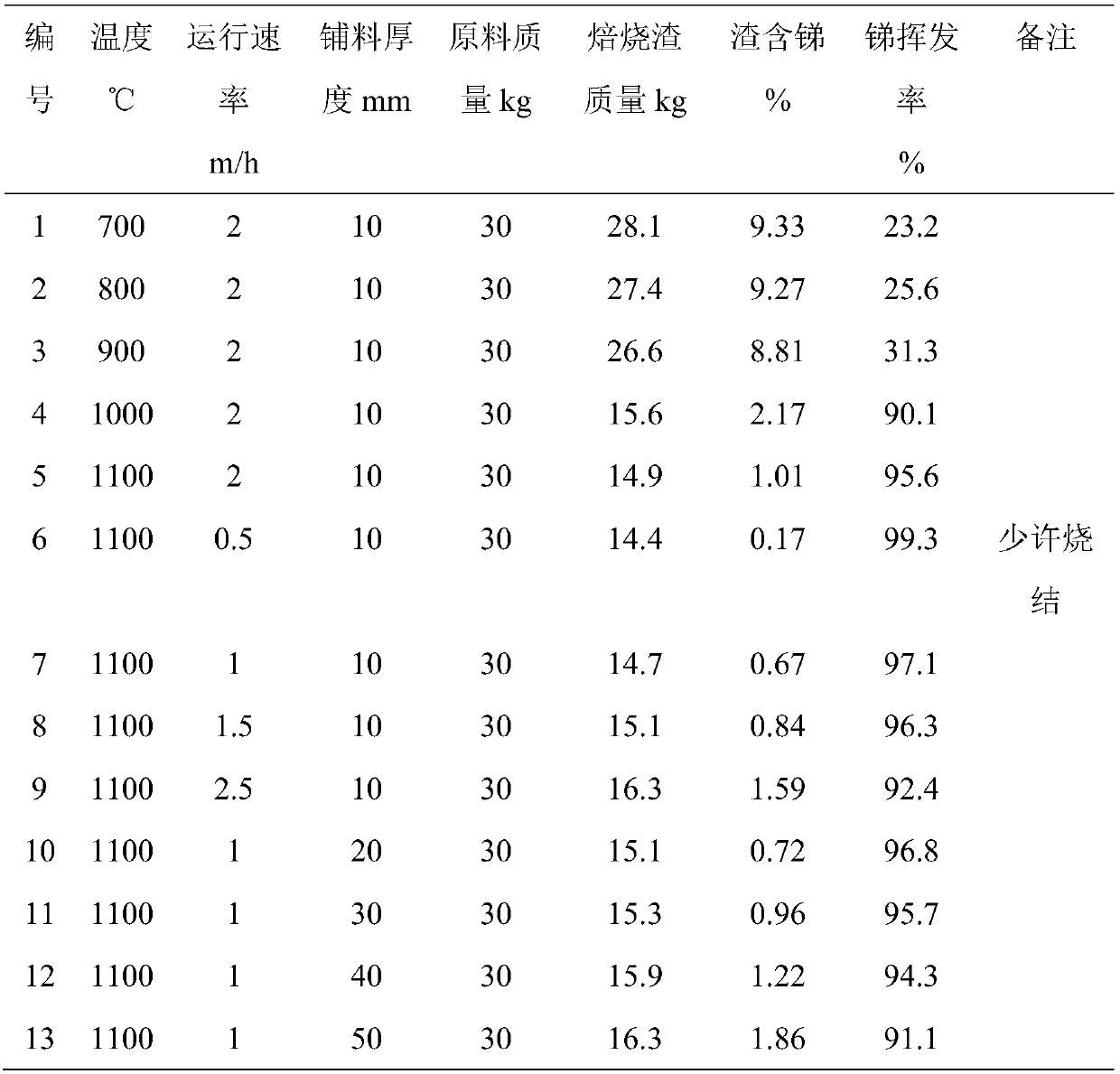

Method used

Image

Examples

Embodiment 1

[0031] The present invention takes the antimony-gold concentrate of a certain antimony smelter in Lengshuijiang, Hunan as the research object, and distributes 37.8kg of antimony-gold concentrate (Sb24.47%; Au 71.10g / t) on the steel strip with a width of 280mm and a thickness of 40mm and control the temperature of the furnace at 1050°C. After the temperature is stabilized, the steel strip is opened at a running speed of 2m / h for 2h, and finally 16.7kg of volatile slag is obtained. The slag contains 0.81% antimony, 157.80g / t gold, and The recovery rate was 98.54%, and the loss rate of gold was only 1.95%.

Embodiment 2

[0033] The present invention takes the antimony-gold concentrate of a certain antimony smelter in Huaihua, Hunan as the research object, and distributes 37.8kg of antimony-gold concentrate (Sb41.53%; Au 32.50g / t) on the steel strip with a width of 280mm and a thickness of 40mm , and control the temperature of the furnace at 950°C. After the temperature is stabilized, the steel strip is opened at a running speed of 2m / h for 3h, and finally 20.62kg of volatile slag is obtained. The slag contains 1.02% antimony and 58.96g / t gold, and the recovery of antimony The rate was 98.66%, and the gold loss rate was 1.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com