Natural gas flue gas moisture removal waste heat recycling system

A natural gas and flue gas technology, applied in the field of natural gas flue gas dehumidification waste heat recycling system, can solve the problems of high equipment investment and operating costs, low temperature corrosion, etc., to achieve full heat utilization, reduce the pressure of low temperature corrosion, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

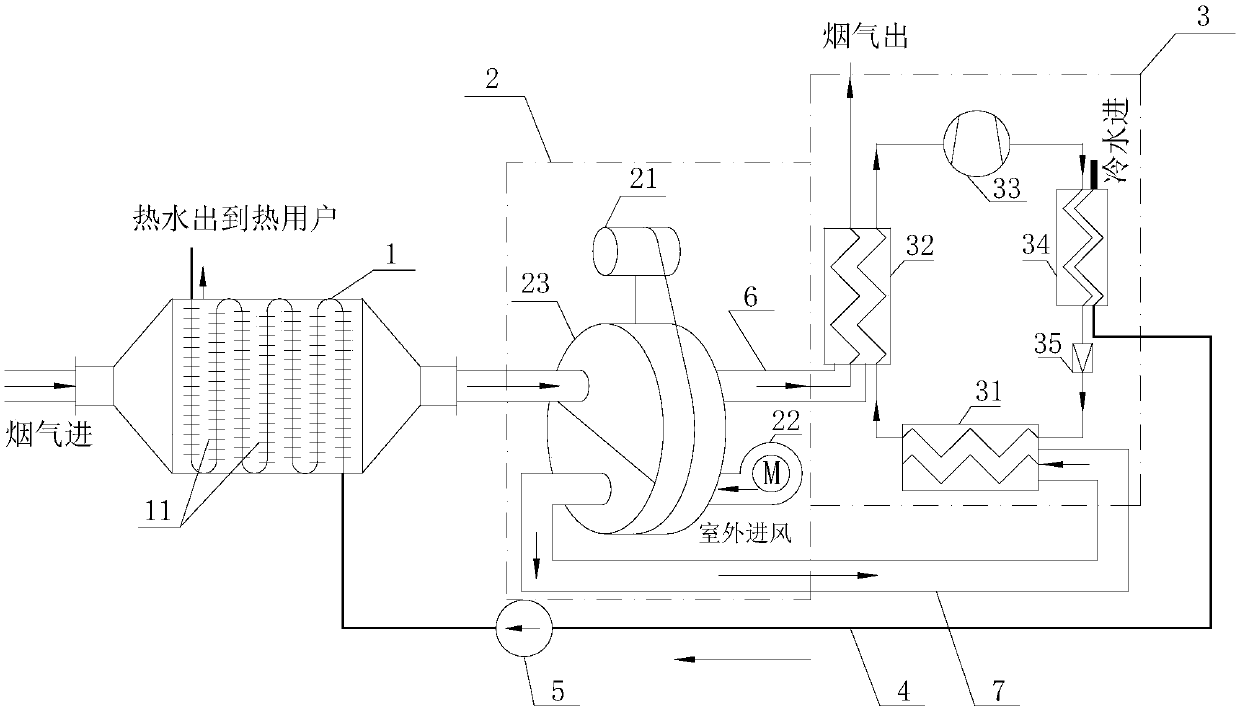

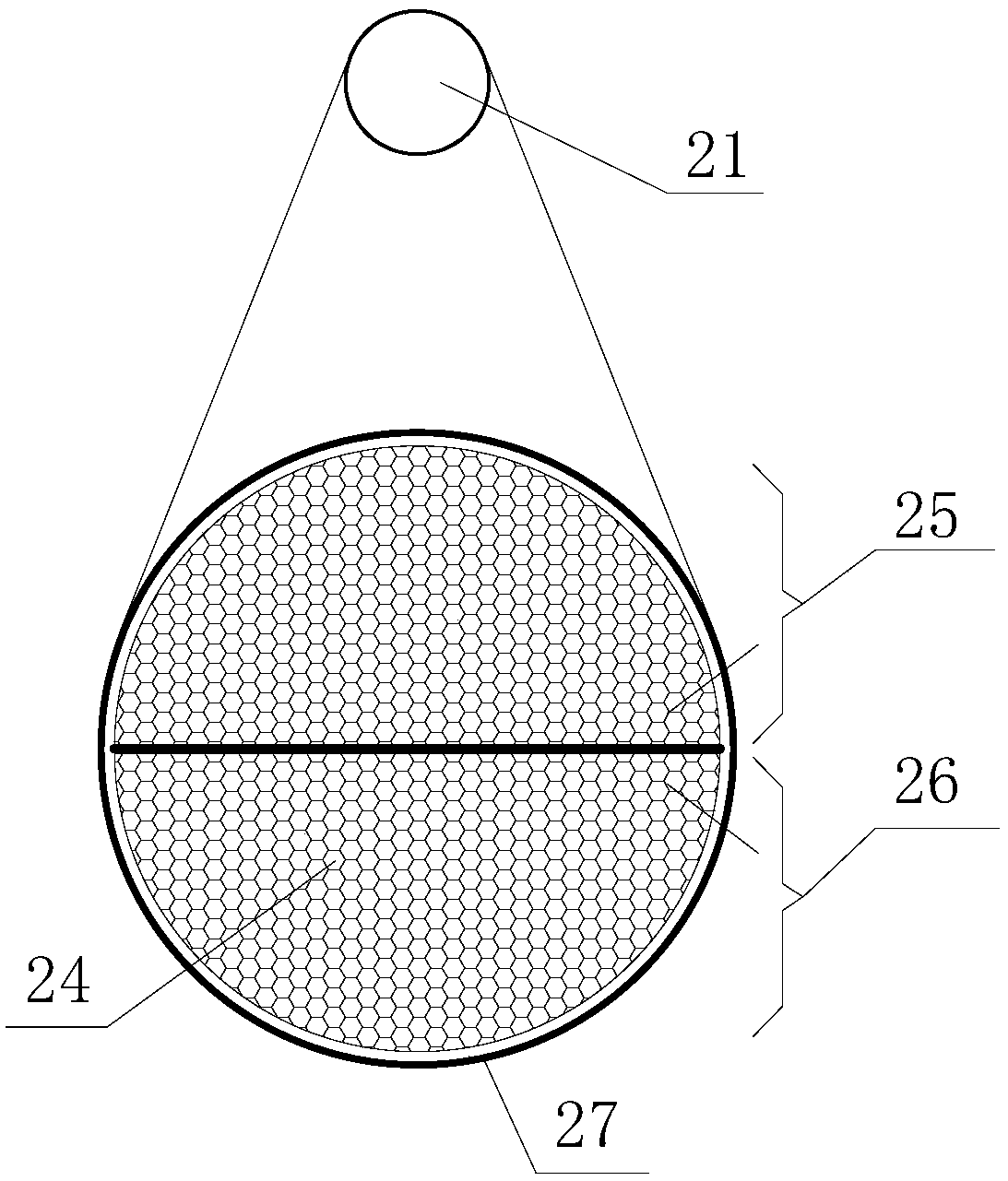

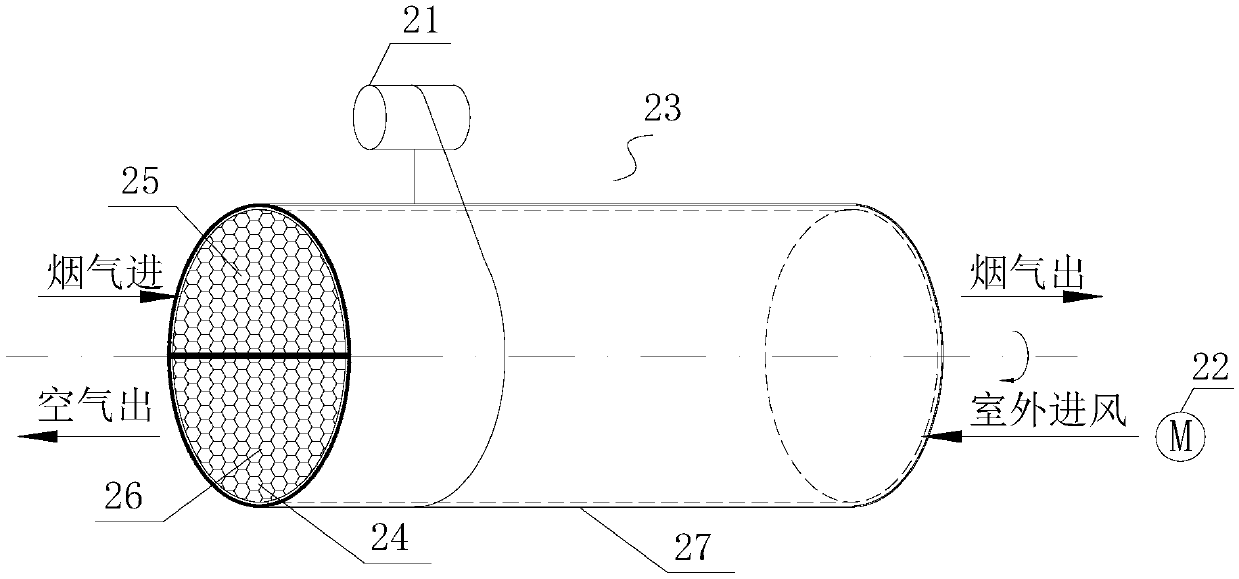

[0027] Such as figure 1 As shown, a natural gas flue gas dehumidification waste heat reuse system of the present invention includes a finned tube heat exchanger 1 , a rotary flue gas dehumidification device 2 and a flue gas source heat pump 3 . Among them, the rotary flue gas dehumidification device 2 includes a drive motor 21 , a fan 22 , a cylindrical dehumidification regenerator 23 and a dehumidifier 24 . The flue gas source heat pump 3 includes a first-stage evaporator 31 , a second-stage evaporator 32 , a compressor 33 , a condenser 34 and a throttle valve 35 . Among them, uniform fins 11 are installed on the tube bundle of finned tube heat exchanger 1; The water inlet o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap