A method for preparing p-i-n structure low-voltage driving organic light-emitting diodes by solution method

A p-i-n, light-emitting diode technology, applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of low carrier mobility, reduced device driving voltage, and high device driving voltage, so as to improve transmission performance, lowering the driving voltage, and the effect of lowering the hole injection barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

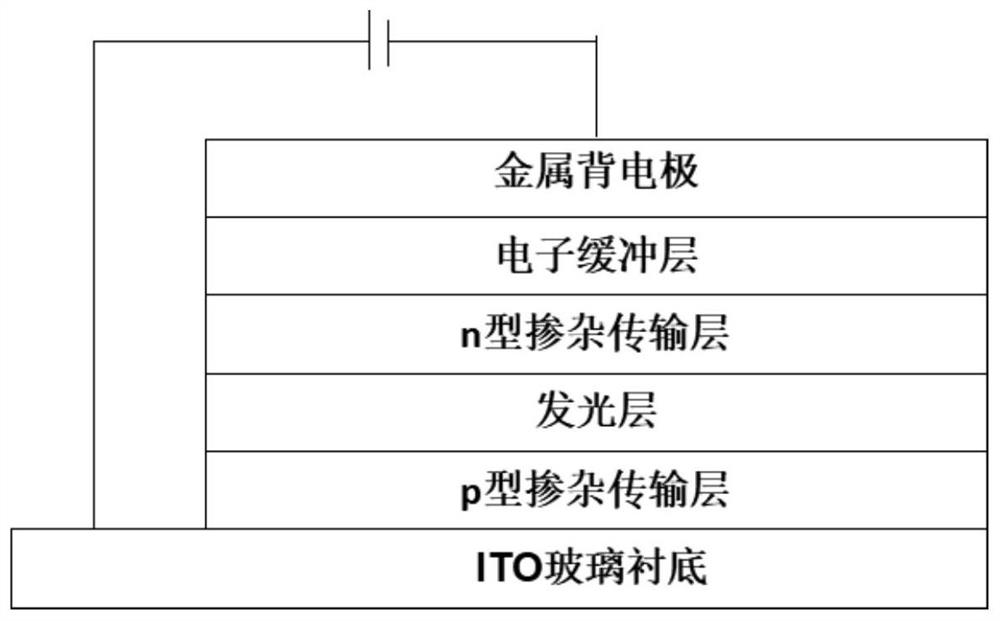

[0032] A method for preparing a p-i-n structure low-voltage driving organic light-emitting diode by a solution method, the specific implementation steps are as follows:

[0033] 1. Etching of ITO glass substrate: The ITO glass substrate is chemically etched to form a strip electrode, and the etched ITO glass substrate is ultrasonically cleaned with ethanol, acetone, and isopropanol for 15 minutes, and then cleaned with deionized water. Rinse and dry at 150°C for 30 minutes;

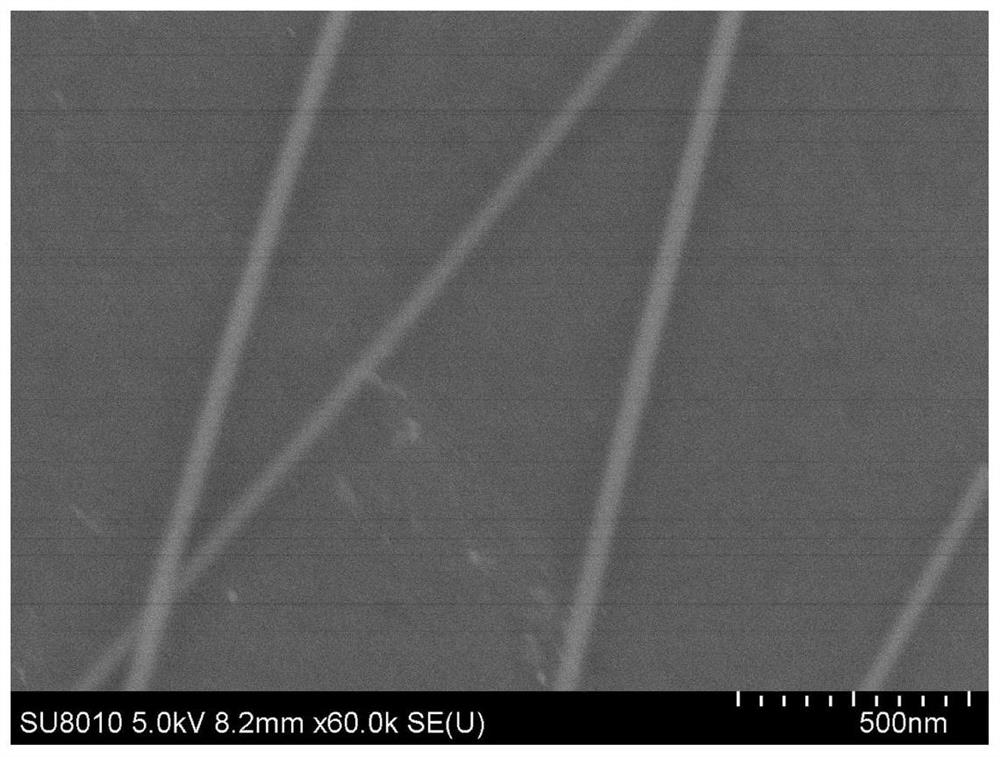

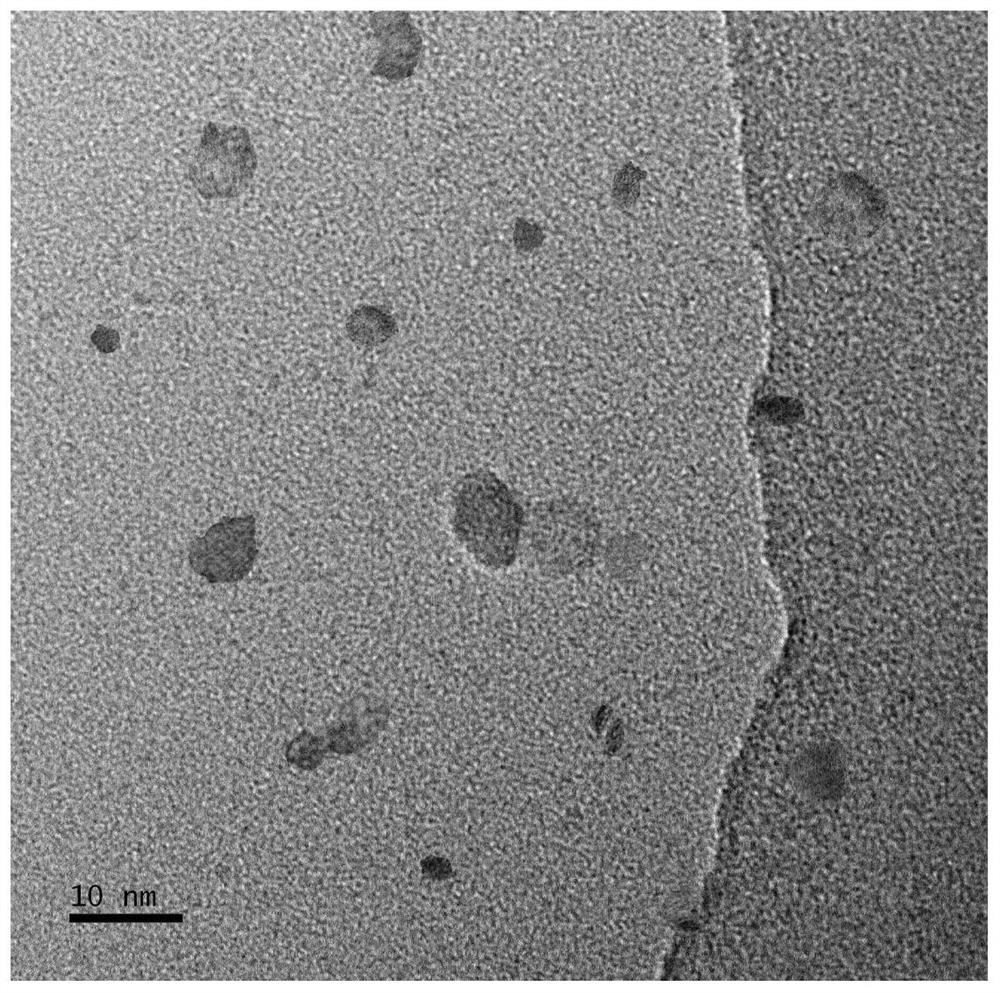

[0034]2. Preparation of the p-type doped transport layer: Weigh 10 mg of PTAA powder with an electronic balance and dissolve it in toluene solution to prepare a PTAA solution with a concentration of 10 mg / ml. AgNWs were dispersed in ethanol solution at a concentration of 10 mg / ml (eg figure 2 shown). The PTAA solution and the AgNWs solution were uniformly mixed at a volume ratio of 20:1 to prepare a PTAA:AgNWs mixed solution. Place the spare ITO glass substrate in step 1 on the homogenizer, take an ap...

Embodiment 2

[0040] The specific implementation method is different except following conditions, and other is identical with embodiment 1:

[0041] Preparation of the p-type doped transport layer: 10 mg of PTAA powder was weighed with an electronic balance and dissolved in toluene solution to prepare a PTAA solution with a concentration of 10 mg / ml. Mix the PTAA solution with the AgNWs solution at a concentration of 10 mg / ml at a volume ratio of 30:1. Place the spare ITO glass substrate in step 1 on the homogenizer, take an appropriate amount of PTAA:AgNWs mixed solution and drop it on the ITO glass substrate, spin-coat at a speed of 1500rpm for 30s, and coat the prepared PTAA:AgNWs The substrate of the film was annealed on a hot stage at 100° C. for 15 minutes, so that a p-type doped transport layer film with a film thickness of 60 nm was prepared on the ITO glass substrate.

Embodiment 3

[0043] The specific implementation method is different except following conditions, and other is identical with embodiment 1:

[0044] Preparation of the p-type doped transport layer: 10 mg of PTAA powder was weighed with an electronic balance and dissolved in toluene solution to prepare a PTAA solution with a concentration of 10 mg / ml. Mix the PTAA solution with the AgNWs solution at a concentration of 10 mg / ml at a volume ratio of 10:1. Place the spare ITO glass substrate in step 1 on the homogenizer, take an appropriate amount of PTAA:AgNWs mixed solution and drop it on the ITO glass substrate, spin-coat at a speed of 1500rpm for 30s, and coat the prepared PTAA:AgNWs The substrate of the film was annealed on a hot stage at 100° C. for 15 minutes, so that a p-type doped transport layer film with a film thickness of 60 nm was prepared on the ITO glass substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com