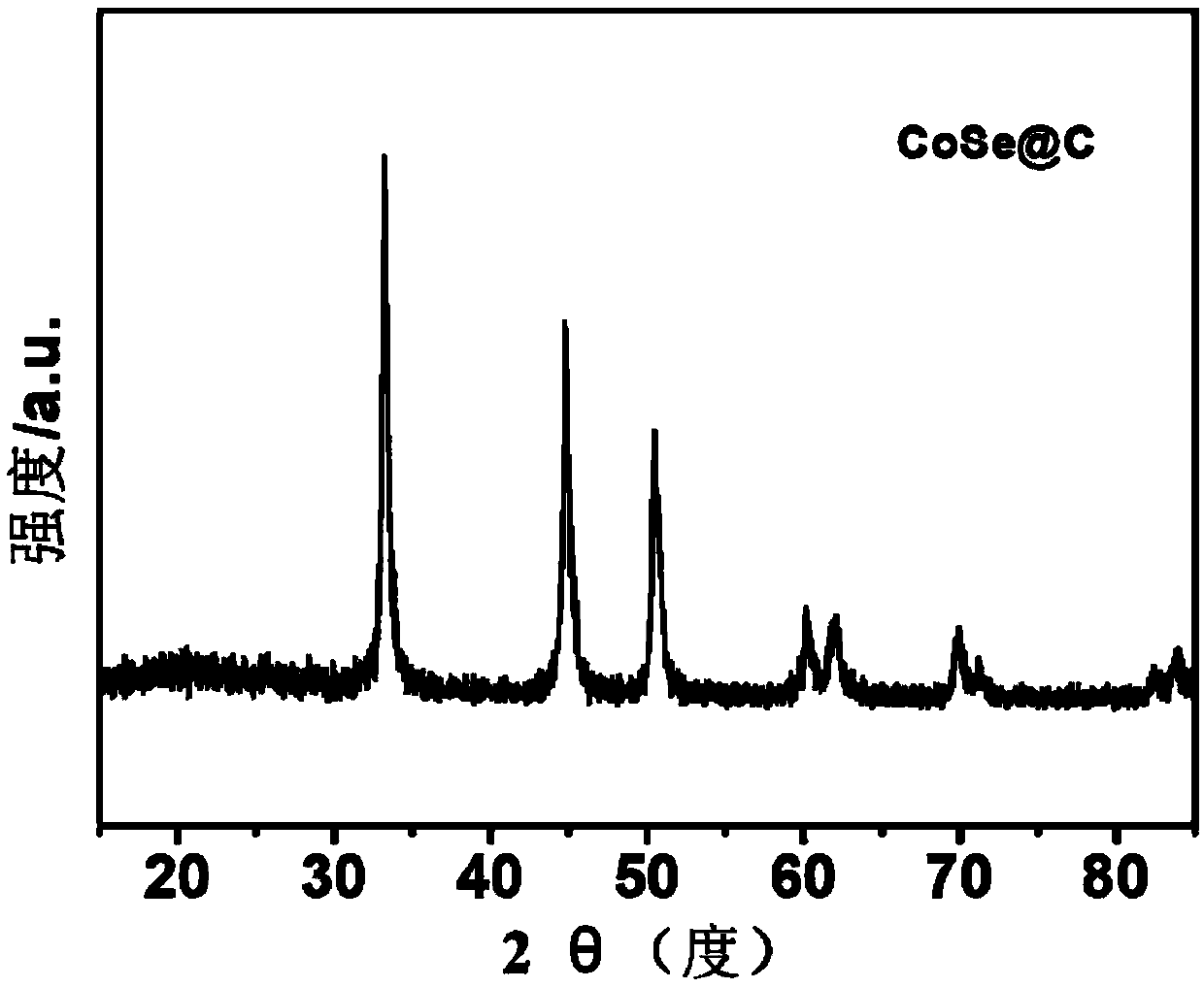

Preparation method and application of in-situ carbon-coated cobalt selenide nano materials

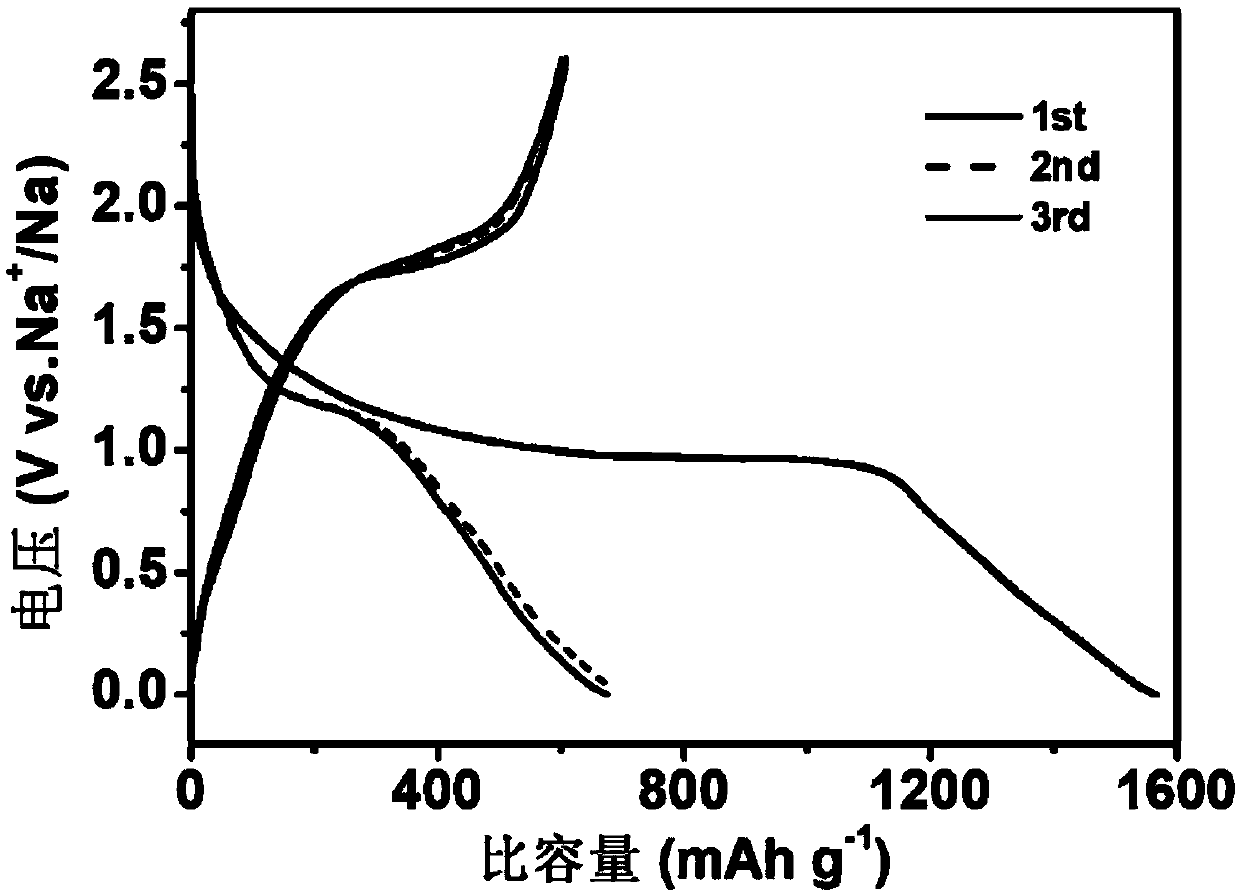

A nano-material and carbon-coated technology, which is applied in the preparation and application of cobalt selenide electrode materials, can solve the problems of cumbersome experimental process, low yield, and high cost, and achieve improved stability and conductivity, high capacity, long-term The effect of cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

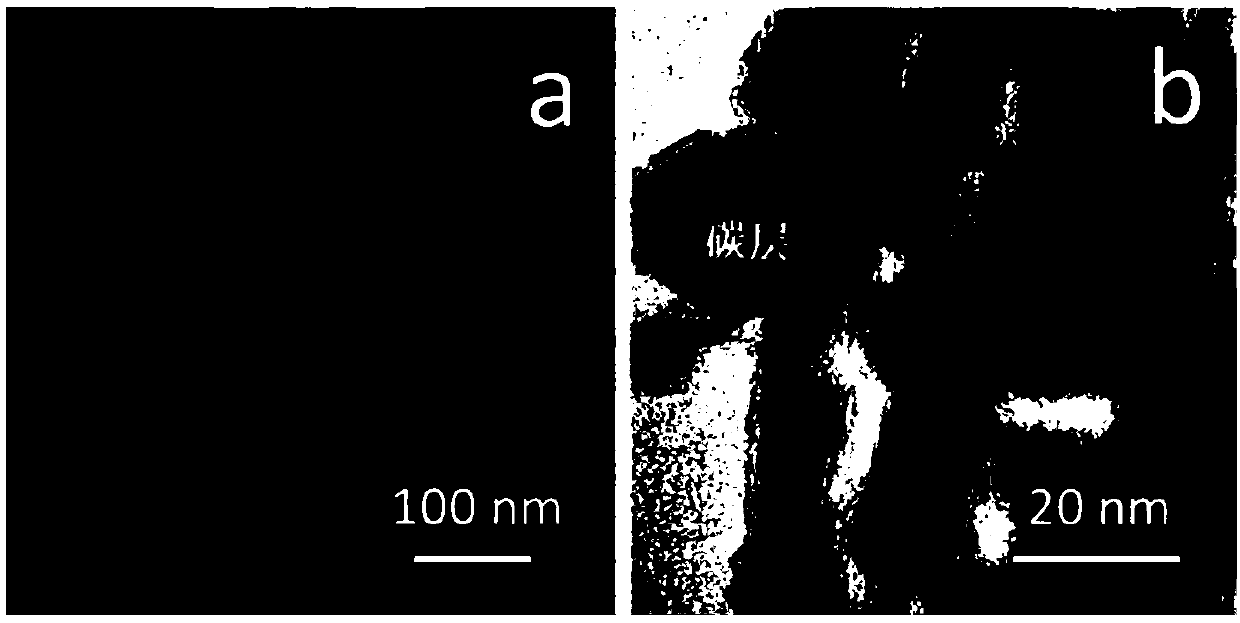

[0020] A method for preparing in-situ carbon-coated cobalt selenide nanomaterials. In this method, without adding any template agent or surfactant, firstly, a one-dimensional rod-shaped precursor is synthesized by hydrothermal method, and then simultaneously Cobalt selenide nanomaterials were prepared by carbon coating and selenization. Specific steps are as follows:

[0021] 1) Weigh 1.5g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 0.6 g of nitrogen triacetic acid (NTA) were dissolved in a mixed solution of 30 mL of distilled water and 10 mL of isopropanol, and stirred evenly to obtain a pink solution.

[0022] 2) Transfer the above mixed solution to a 50mL stainless steel autoclave, put it in a constant temperature oven at 180°C for 6 hours, and after cooling to room temperature, filter the obtained product with suction, and wash it with distilled water and absolute ethanol several times, and put it in a vacuum Drying in an oven yields a pink precursor.

[0023] 3) ...

Embodiment 2

[0029] A method for preparing in-situ carbon-coated cobalt selenide nanomaterials. In the method, without adding any template agent or surfactant, firstly, a one-dimensional rod-shaped precursor is synthesized by hydrothermal method, and then simultaneously Cobalt selenide nanomaterials were prepared by carbon coating and selenization. Specific steps are as follows:

[0030] 1) Weigh 1.5g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 0.6 g of nitrogen triacetic acid (NTA) were dissolved in a mixed solution of 20 mL of distilled water and 20 mL of isopropanol, and stirred evenly to obtain a pink solution.

[0031] 2) Transfer the above mixed solution to a 50mL stainless steel autoclave, put it in a constant temperature oven at 180°C for 6 hours, and after cooling to room temperature, filter the resulting product with suction, wash it with distilled water and absolute ethanol several times, and put it in a vacuum Drying in an oven yields a pink precursor.

[0032] 3) Mix ...

Embodiment 3

[0034] A method for preparing in-situ carbon-coated cobalt selenide nanomaterials. In the method, without adding any template agent or surfactant, firstly, a one-dimensional rod-shaped precursor is synthesized by hydrothermal method, and then simultaneously Cobalt selenide nanomaterials were prepared by carbon coating and selenization. Specific steps are as follows:

[0035] 1) Weigh 1.5g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 0.6 g of nitrogen triacetic acid (NTA) were dissolved in a mixed solution of 10 mL of distilled water and 30 mL of isopropanol, and stirred evenly to obtain a pink solution.

[0036] 2) Transfer the above mixed solution to a 50mL stainless steel autoclave, put it in a constant temperature oven at 180°C for 6 hours, and after cooling to room temperature, filter the resulting product with suction, wash it with distilled water and absolute ethanol several times, and put it in a vacuum Drying in an oven yields a pink precursor.

[0037] 3) Mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com