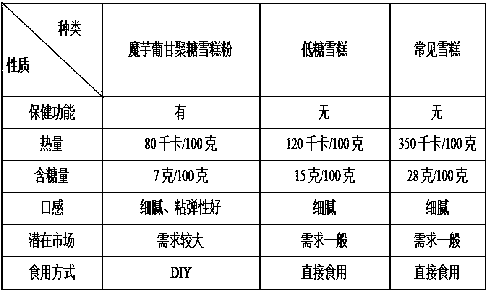

Konjac glucomannan ice cream powder and preparation method thereof

A technology of konjac glucomannan and ice cream powder, which is applied in the direction of food ingredients as taste improver, frozen desserts, functions of food ingredients, etc. problem, to achieve the effect of small specific surface area, improved edible value, and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of preparation method of konjac glucomannan ice cream powder comprises the following steps:

[0029] (1) Mixing of raw materials: prepared according to parts by mass, take 0.07 parts of konjac glucomannan, 0.03 parts of stevia, 95 parts of milk powder, 75 parts of glutinous rice flour, 10 parts of whipped cream, 70 parts of eggs, 0.8 parts of maltose syrup, trehalose 0.7 parts, 4 parts of xylitol and 75 parts of water, mix well to make a mixture, set aside;

[0030] (2) Sterilization: Take the mixture in step (1), and sterilize it with high-pressure steam. The sterilization temperature is controlled at 80°C for 10 seconds;

[0031] (3) Vacuum concentration: Concentrate the sterilized mixture in step (2) under a vacuum of 650mmHg and a temperature of 55°C to remove part of the water;

[0032] (4) High-pressure homogenization: the mixture concentrated in step (3) is graded and homogenized in a high-pressure homogenizer, and the homogenization temperat...

Embodiment 2

[0034] Embodiment 2 A kind of preparation method of konjac glucomannan ice cream powder comprises the following steps:

[0035] (1) Raw material mixing: prepared according to mass parts, take 0.08 parts of konjac glucomannan, 0.05 parts of stevia, 98 parts of milk powder, 80 parts of glutinous rice flour, 13 parts of whipped cream, 72 parts of eggs, 1.0 parts of malt syrup, trehalose 0.9 parts, 5 parts of xylitol and 77 parts of water, mix well to make a mixture, set aside;

[0036] (2) Sterilization: Take the mixture in step (1), and sterilize it with high-pressure steam. The sterilization temperature is controlled at 83°C for 12 seconds;

[0037] (3) Vacuum concentration: Concentrate the sterilized mixture in step (2) under a vacuum of 650mmHg and a temperature of 57°C to remove part of the water;

[0038](4) High-pressure homogenization: the mixture concentrated in step (3) is graded and homogenized in a high-pressure homogenizer, and the homogenization temperature is 68°C...

Embodiment 3

[0040] Embodiment 3 A kind of preparation method of konjac glucomannan ice cream powder comprises the following steps:

[0041] (1) Mixing of raw materials: prepared according to parts by mass, take 0.09 parts of konjac glucomannan, 0.08 parts of stevia, 100 parts of milk powder, 85 parts of glutinous rice flour, 15 parts of light cream, 75 parts of eggs, 1.2 parts of malt syrup, trehalose 1 part, 6 parts of xylitol and 80 parts of water, mix well to make a mixture, set aside;

[0042] (2) Sterilization: take the mixture in step (1), and sterilize it with high-pressure steam. The sterilization temperature is controlled at 85°C for 15 seconds;

[0043] (3) Vacuum concentration: Concentrate the sterilized mixture in step (2) under a vacuum of 650mmHg and a temperature of 60°C to remove part of the water;

[0044] (4) High-pressure homogenization: the mixture concentrated in step (3) is graded and homogenized in a high-pressure homogenizer, and the homogenization temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com