Baking stick for weight-reducing fast food and preparation method thereof

A baking and raw material technology, which is applied in the field of baking sticks for weight loss meal replacement and its preparation, can solve the problems of excessive fat intake, obesity, and failure to achieve weight loss meal replacement, so as to maintain color, reduce fat accumulation, and avoid oil The effect of intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

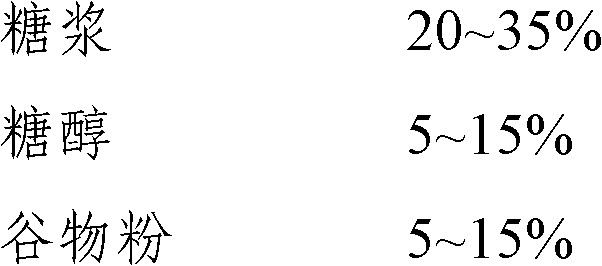

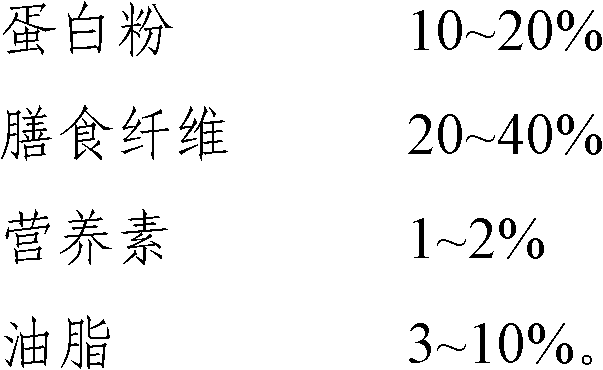

Method used

Image

Examples

Embodiment 1

[0026] Take 5kg of whey protein, 10kg of soybean protein, 5kg of milk protein, 5kg of flour, 5kg of konjac gum, 5kg of oat fiber, 15kg of wheat fiber, 0.034kg of ammonium bicarbonate, 0.34kg of sodium bicarbonate, and 2kg of calcium carbonate in a noodle mixer Mix well to form a powder.

[0027] Get 8kg of medium-chain triglycerides and heat it to cause it to melt.

[0028] Take 10kg of fructose syrup, 10kg of maltose syrup, and 15kg of sorbitol, heat the above syrup and sugar alcohol to boiling and cool to 70°C, add the above medium-chain triglycerides into the syrup, stir evenly and cool to 40-50°C, Add the powder while stirring, stir evenly, and make a dough, and make it into a stick in the mold.

[0029] Put the above-mentioned rod-shaped mixture into an oven and bake at 180°C for 8 minutes to obtain a finished baked rod.

Embodiment 2

[0031] Take 3kg of egg protein, 10kg of peanut protein, 12kg of wheat flour, 5kg of konjac gum, 5kg of citrus fiber, 10kg of oat fiber, 0.34kg of ammonium bicarbonate, and 0.5kg of L-carnitine, and mix them uniformly in a noodle mixer to form powder.

[0032] Get 6kg of medium-chain triglycerides and heat it to cause it to melt.

[0033] Take 28kg of glucose syrup and 5kg of sorbitol, mix the above syrup and sorbitol, heat to boiling and cool to 70°C, add the above medium chain triglycerides to the mixture of syrup and sorbitol, stir evenly and cool to 40°C ~50°C, add powder while stirring, stir evenly, knead into a dough, and make it into a rod shape in the mold.

[0034] Put the above-mentioned rod-shaped mixture into an oven and bake at 200°C for 9 minutes to obtain a finished baked rod.

Embodiment 3

[0036] Take 5kg of whey protein, 5kg of casein protein, 15kg of rice flour, 5.5kg of konjac gum, 15kg of dextrin, 5kg of inulin, 0.38kg of sodium bicarbonate, vitamin B 1 0.0005kg, Vitamin B 2 0.0005kg is mixed evenly in a noodle mixer to form a powder.

[0037] Get 7.5kg of medium-chain triglycerides and heat to cause it to melt.

[0038] Take 20kg of malt syrup, 12kg of corn syrup and 9kg of maltitol, heat the above syrup and sugar alcohol to boiling and cool to 70°C, add the above medium chain triglycerides into the syrup, stir evenly and cool to 40-50°C, Add the powder while stirring, stir evenly, and make a dough, and make it into a stick in the mold.

[0039] Put the above-mentioned rod-shaped mixture into an oven and bake at 190°C for 8 minutes to obtain a finished baked rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com