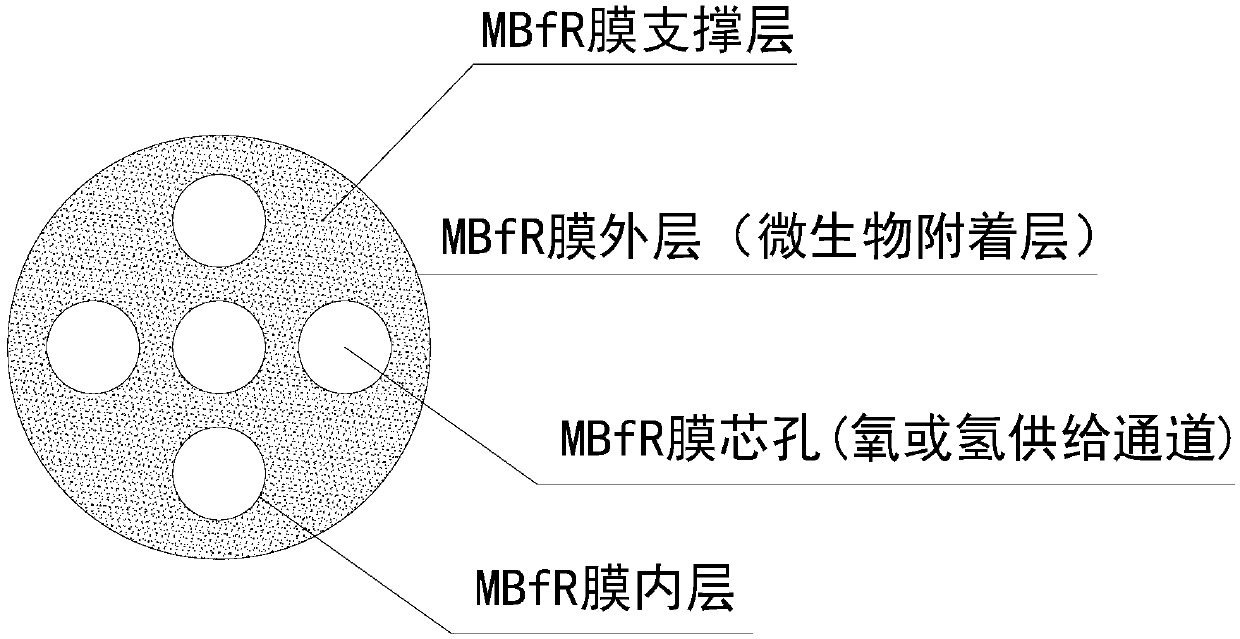

Microbial carrier hybrid MBfR membrane and preparation method thereof

A microbial carrier and hybridization technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as product failure, hollow fiber membranes are easy to break, cortex shedding, etc., and achieve simple operation, simple preparation method, anti The effect of enhancing the ability of water force and soda shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

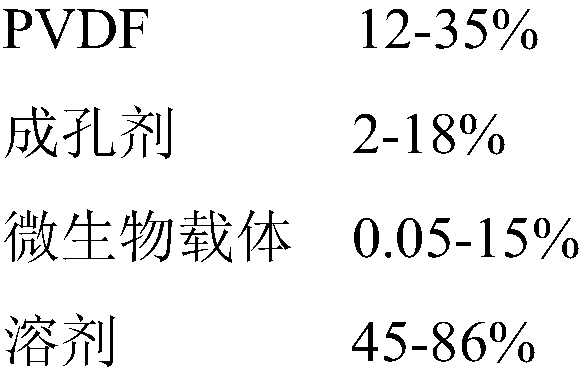

Embodiment 1

[0047] Each component of embodiment 1 prepares the casting solution of MBfR membrane by following weight ratio: weight-average molecular weight is 15% of PVDF resin powder of 700,000, polyvinylpyrrolidone (PVP-K15) powder 12%, polyethylene glycol (PEG- 600) liquid 3%, 200 mesh particle diameter nitric acid modified activated carbon material 2%, commercially available carbon nanotube 3%, dimethylacetamide (DMAc) solvent 65%, with above material by certain order (at first PVP -Add K15 and PEG-600 into DMAC solution, stir for 20 minutes, then add activated carbon and carbon nanotubes, stir for 30 minutes to 2 hours, and finally add PVDF. Activated carbon and carbon nanotubes can also be added first, but not last, Otherwise it will lead to uneven mixing, and uneven mixing will make the final product defective.) Add it to the reactor, keep the jacket temperature of the reactor at 60°C, stir for 12 hours at a stirring speed of 150rpm, and let the material liquid stand for 12 hours F...

Embodiment 2

[0049] Embodiment 2 Each component prepares the casting film solution of MBfR membrane by following weight ratio: weight average molecular weight is 18% of PVDF resin powder of 700,000, polyvinylpyrrolidone (PVP-K15) powder 8%, 600 mesh particle diameter nitric acid modification Activated carbon material 0.5%, commercial carbon nanotube 4.5%, dimethylacetamide (DMAc) solvent 69%. The spinning process is the same as in Example 1, spinning at a speed of 15m / min, and the finished product properties measured are as follows: the fiber tensile elongation at break is 165%, the fiber tensile strength at break is 3.6N, and the outer aperture of the hollow fiber membrane is 0.1 Micron, inner diameter 22 microns.

Embodiment 3

[0051] Embodiment 3 Each component prepares the casting liquid of MBfR membrane by following weight ratio: weight average molecular weight is 25% of PVDF resin powder of 700,000, polyethylene glycol (PEG-600) liquid 15%, commercially available carbon nanotube 5% %, dimethylformamide (DMF) solvent 55%. The spinning process is the same as in Example 1, spinning at a speed of 45m / min, and the finished product properties measured are as follows: the fiber tensile elongation at break is 176%, the fiber tensile strength at break is 4.2N, and the outer diameter of the hollow fiber membrane is 0.05 Micron, the inner hole diameter is 15 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com