A high electron transport core-shell znin 2 the s 4 Nanosheet/ta 3 no 5 Preparation method and application of composite photocatalyst

A composite photocatalysis, znin2s4 technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of undiscovered, reduced light absorption, limited wide application, etc. Improve the effect of electron transmission, non-toxic and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] (1) Weigh 0.178g of zinc nitrate, 0.382g of indium nitrate, and 0.225g of thioacetamide (TAA), dissolve it in 25ml of deionized water, stir for 15min until it dissolves, and obtain a clear solution; weigh hexadecane Add 0.15 g of trimethylammonium bromide (CTAB) into the above clear solution, and stir for 15 min to obtain a mixed solution.

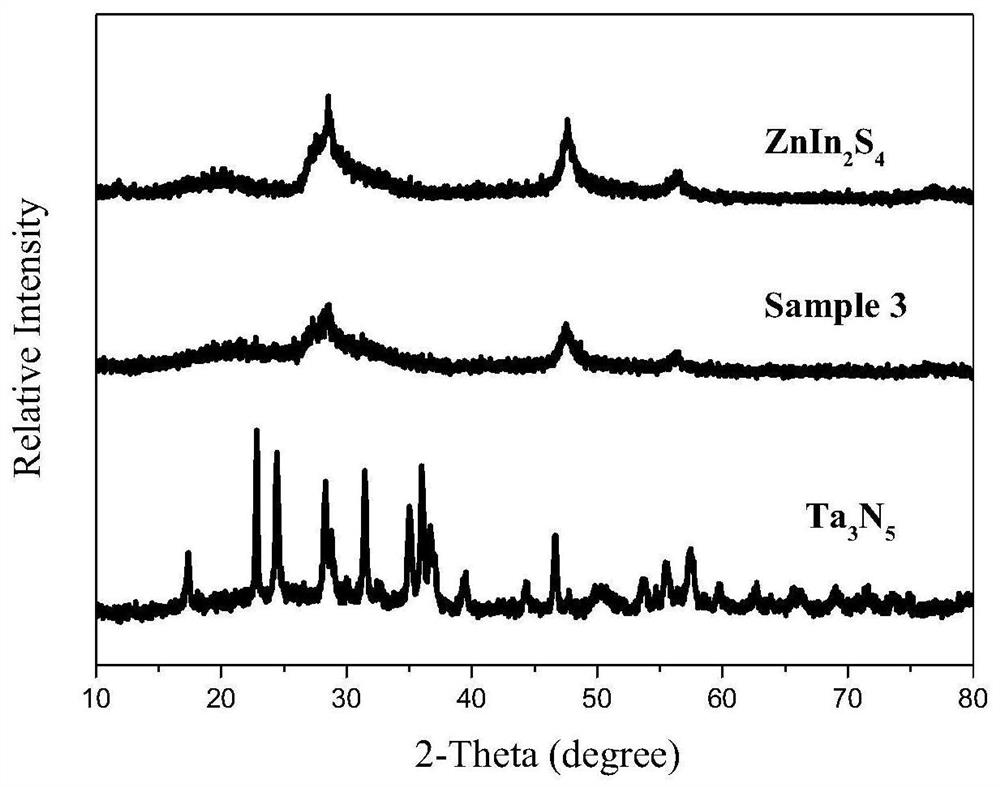

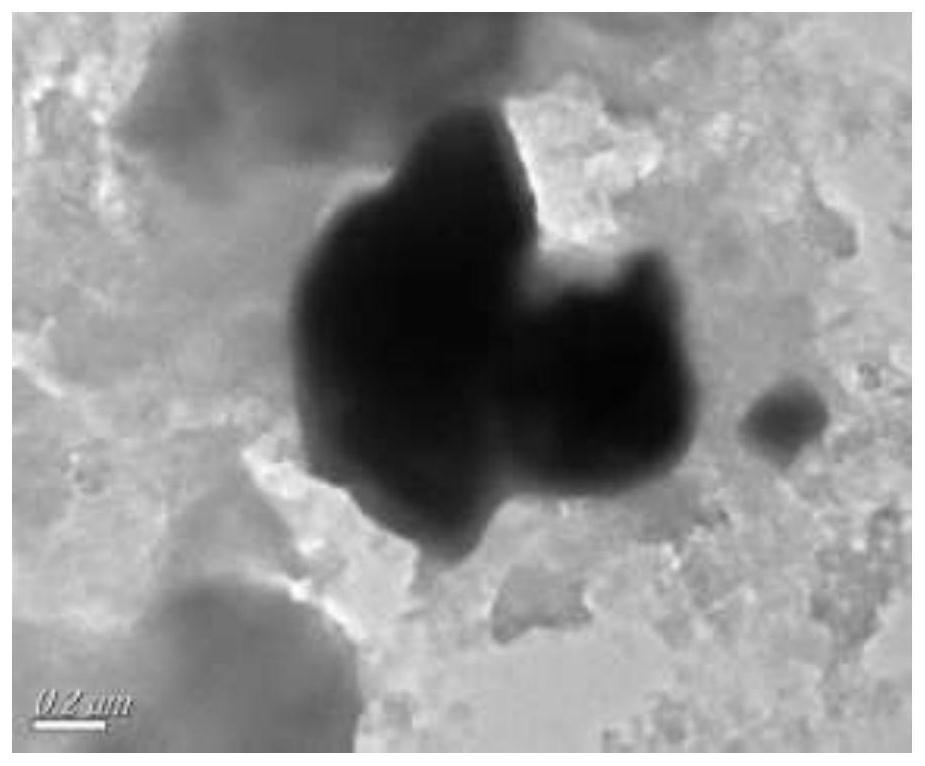

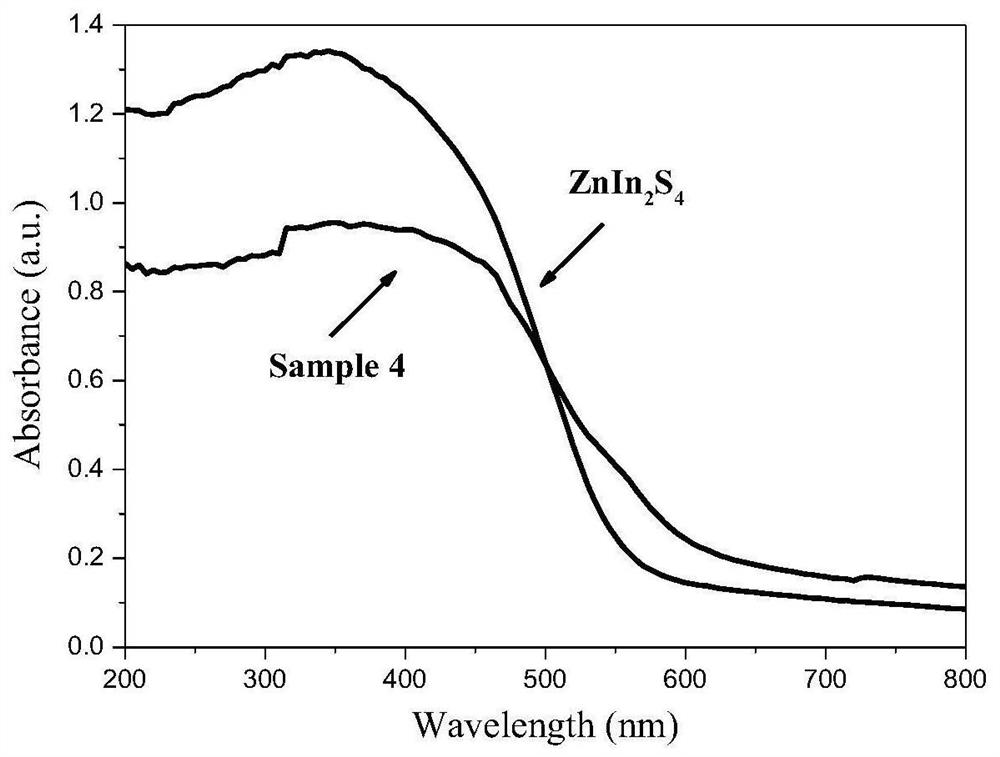

[0026] (2) Weigh Ta 3 N 5 0.0026g was added to the mixed solution in step (1), stirred for 4 minutes, ultrasonicated for 3 minutes, repeated twice to obtain a light red dispersion, which was transferred to a reaction kettle for constant temperature reaction, the reaction temperature was 120 ° C, and the reaction time was 3 hours. After the reaction is finished, cool to room temperature, centrifuge the obtained substance, wash repeatedly with deionized water and absolute ethanol, and then put it in a vacuum drying oven to dry to obtain ZnIn 2 S 4 / Ta 3 N 5 Composite photocatalytic materials. Among them Ta 3 N 5 The content o...

example 2

[0029] (1) Weigh 0.3204g of zinc nitrate, 0.6876g of indium nitrate, and 0.405g of thioacetamide (TAA), dissolve them in 30ml of deionized water, stir for 20min until they dissolve, and obtain a clear solution; weigh hexadecane Add 0.27 g of trimethylammonium bromide (CTAB) into the above clear solution, and stir for 20 min to obtain a mixed solution.

[0030] (2) Weigh Ta 3 N 5 0.0138g was added to the mixed solution of step (1), stirred for 6 minutes, ultrasonicated for 6 minutes, repeated twice to obtain a light red dispersion, which was transferred to a reaction kettle for constant temperature reaction, the reaction temperature was 140 ° C, and the reaction time was 5 hours. After the reaction is finished, cool to room temperature, centrifuge the obtained substance, wash repeatedly with deionized water and absolute ethanol, and then put it in a vacuum drying oven to dry to obtain ZnIn 2 S 4 / Ta 3 N 5 Composite photocatalytic materials. Among them Ta 3 N 5 The cont...

example 3

[0034] (1) Weigh 0.534g of zinc nitrate, 1.146g of indium nitrate, and 0.675g of thioacetamide (TAA), dissolve it in 30ml of deionized water, stir for 15min until it dissolves, and obtain a clear solution; weigh hexadecane Add 0.45 g of trimethylammonium bromide (CTAB) into the above clear solution, and stir for 25 minutes to obtain a mixed solution.

[0035] (2) Weigh Ta 3 N 5 0.0385g was added to the mixed solution of step (1), stirred for 8 minutes, ultrasonicated for 6 minutes, repeated twice to obtain a light red dispersion, which was transferred to a reaction kettle for constant temperature reaction, the reaction temperature was 140 ° C, and the reaction time was 6 hours. After the reaction is finished, cool to room temperature, centrifuge the obtained substance, wash repeatedly with deionized water and absolute ethanol, and then put it in a vacuum drying oven to dry to obtain ZnIn 2 S 4 / Ta 3 N 5 Composite photocatalytic materials. Among them Ta 3 N 5 The conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com