Three-dimensional micro-carrier cell adsorption culture method

A technology of cell adsorption and cell culture, applied in general culture methods, tissue culture, biochemical equipment and methods, etc., can solve the problem that the two-dimensional microenvironment cannot simulate and reproduce the three-dimensional microenvironment, the survival rate and function of stem cells Reduce, repair and regenerate the function of decline, etc., to achieve the effect of simple cultivation, simplified operation, and promotion of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1, the method that adopts stirrer rotation adsorption method to carry out three-dimensional microcarrier cell adsorption

[0030] 1. Microcarrier preparation: Weigh 200 mg of microcarrier powder, carry out ultraviolet sterilization, and pour it into a sterile built-in impeller cell culture bottle (such as figure 1 shown); prepare three groups;

[0031] 2. Cell preparation: Prepare adipose-derived mesenchymal stem cell suspension in advance, 5×10 6 Cells were resuspended in 60mL complete medium for use; prepare three groups;

[0032] 3. Cell inoculation: mix the above cell suspension into the cell culture flask with built-in impeller, and mix with 200mg microcarrier;

[0033] 4. Cell adsorption: Place the built-in impeller cell culture flask on a low-speed stirrer and put it in a 37°C, 5% carbon dioxide incubator for 80rpm stirring, so that the cells adhere to the microcarrier by rotating;

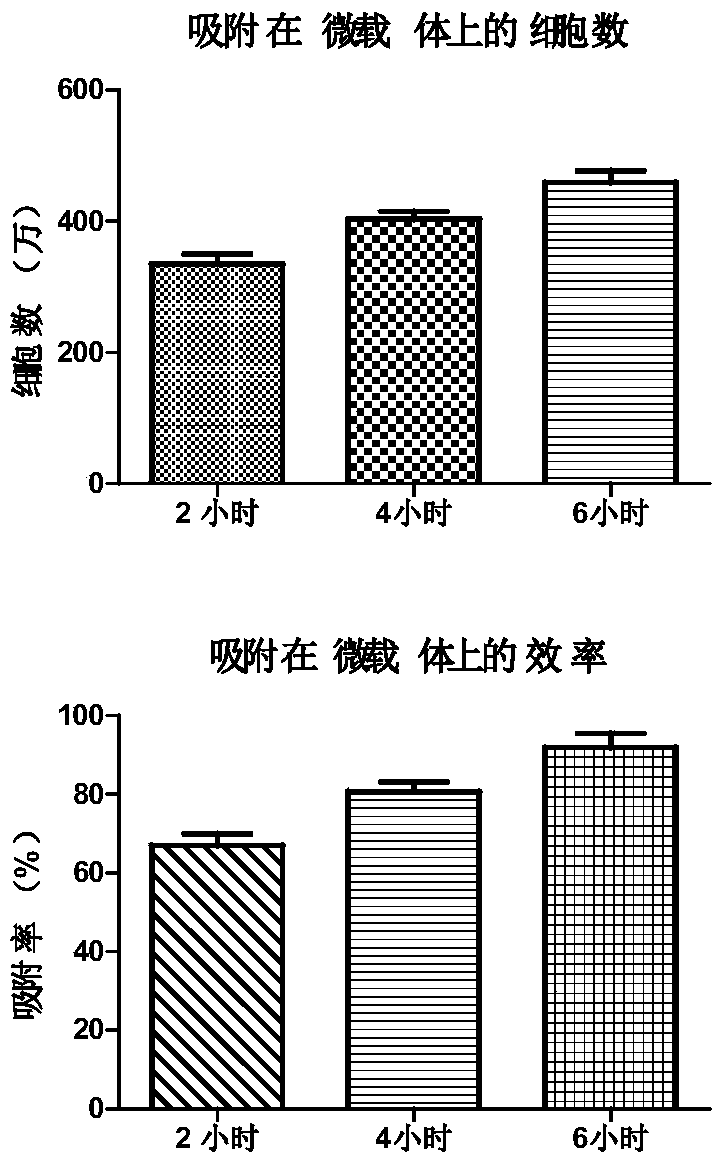

[0034] 5. In situ counting to obtain the adsorption rate:

[0035...

Embodiment 2

[0038] Embodiment 2, the method for the three-dimensional microcarrier cell adsorption of small volume high density swelling adsorption method

[0039] 1. Microcarrier preparation: Weigh 20 mg of microcarrier powder for ultraviolet sterilization and set aside;

[0040] 2. Cell preparation: Prepare adipose-derived mesenchymal stem cell suspension in advance, with a density of 2.5×10 6 cells / mL, prepare 200 μL for every 20 mg of three-dimensional microcarriers;

[0041] 3. Cell inoculation: pipette 200 μL of cell suspension and add dropwise to 20 mg of microcarrier to fully mix the cell suspension and microcarrier;

[0042] 4. Cell adsorption: put the microcarrier of the mixed cell suspension into a 37°C, 5% carbon dioxide incubator and incubate for 2 hours to make the cells adhere to the microcarrier;

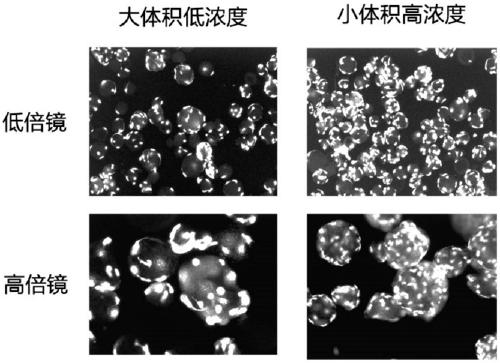

[0043] 5. Cell culture: After the cells adhere, add 3mL of complete medium, put it in a 37°C, 5% carbon dioxide incubator and culture it for 24 hours, then observe the cells; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com