Wheat fiber powder and preparation method thereof

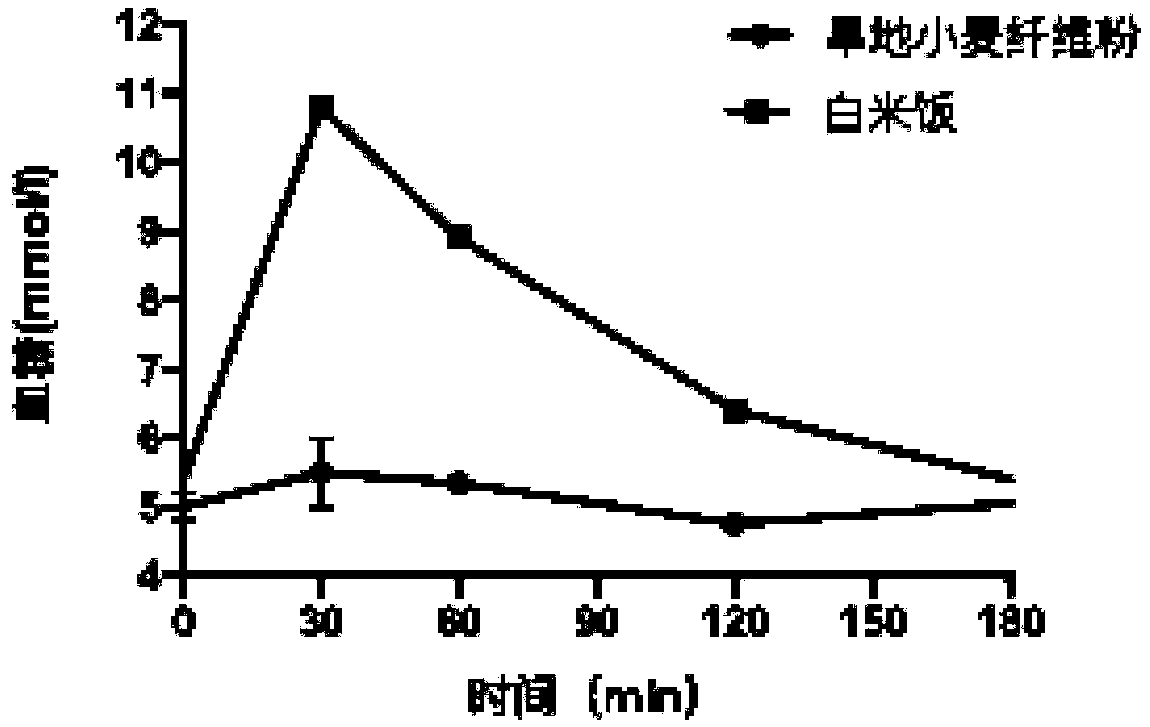

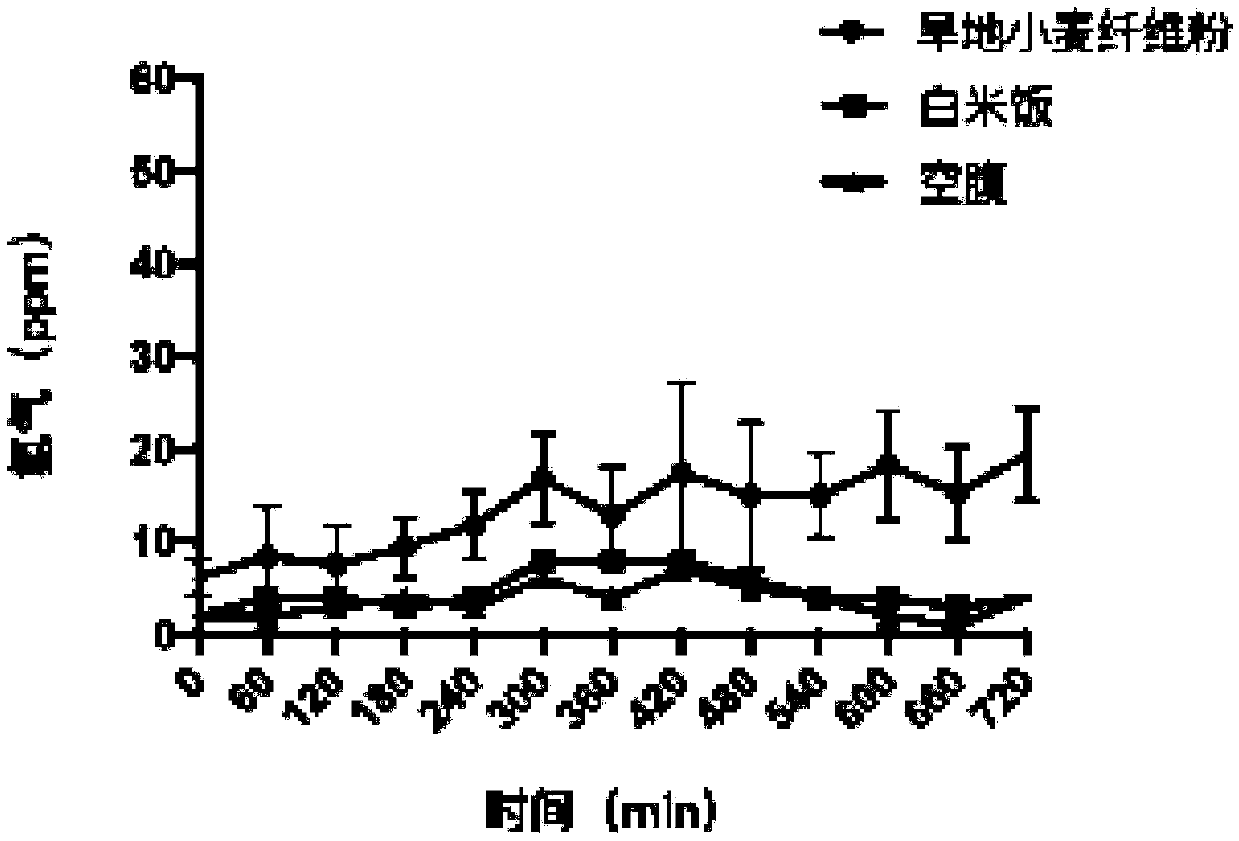

A wheat fiber powder and wheat technology, applied in the field of wheat fiber powder and its preparation, can solve problems such as low efficiency and poor taste, and achieve the effects of high peak hydrogen production, stable blood sugar, and long duration of hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. The preparation process of wheat fiber powder

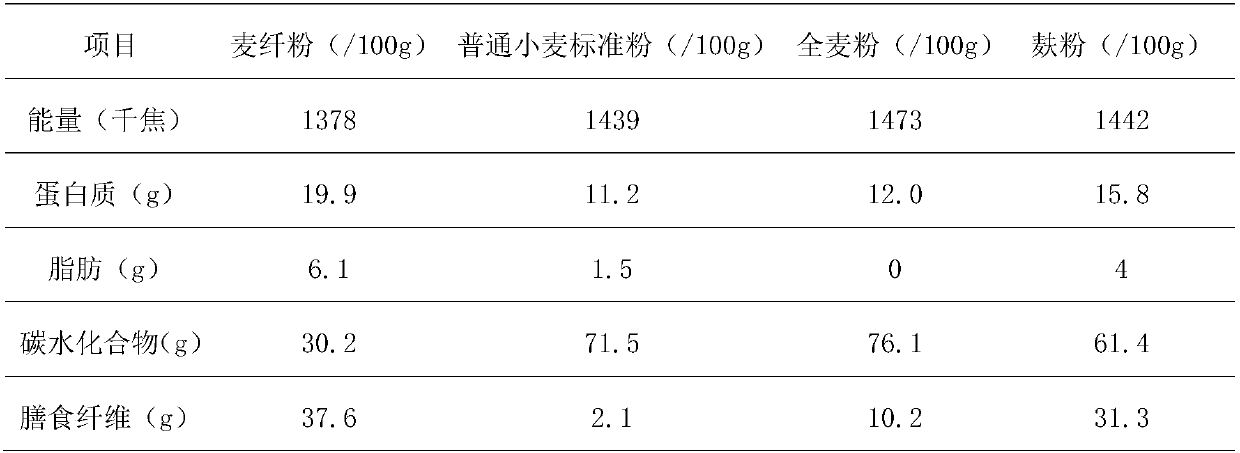

[0040] Wheat fiber powder is composed of upland organic wheat, plateau highland barley, Jingle tartary buckwheat and Youyu oat, wherein the weight percentage content of each component is: 60% (upland wheat), 10% (highland barley), 10% (tartary buckwheat ), 20% (oats).

[0041] The above four grain raw materials all contain the skin and are not dehulled or dehulled.

[0042]The dry land organic wheat, plateau barley, Jingle tartary buckwheat and Youyu oats stored in the cold chain are first cleaned to remove stones, weeds and other substances mixed in the above grain raw materials; then the raw materials are washed with clean water to further remove Adhesive soil and dust; then carry out the wheat moistening process, add an appropriate amount of warm water to the raw materials, then put the above raw materials into the warehouse for a certain period of time, and adjust the moisture content of the raw materials to about ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com