A kind of energy-saving and environment-friendly phosphorus pentoxide production process

A phosphorus pentoxide and production process technology, applied in the field of phosphorus pentoxide production process, can solve the problems of heavy air pollution, inability to recycle, not green enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]An energy-saving and environment-friendly phosphorus pentoxide production process, the steps are as follows:

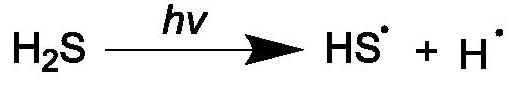

[0055] (1) Air drying: the air is passed into the drying chamber, so that the air pressure in the drying chamber is 1.8atm, and the drying chamber contains a desiccant, and the content of the desiccant in the chamber is 200g / m 3 , the drying chamber is equipped with an ultraviolet lamp, the wavelength of ultraviolet light is 280nm, and the ultraviolet light is irradiated for 45 minutes to obtain dry gas;

[0056] The desiccant is P 2 S 5 ;

[0057] (2) Melting of yellow phosphorus: heating yellow phosphorus to 70°C to melt to obtain fused yellow phosphorus;

[0058] (3) Oxidation: Pass dry gas and melted yellow phosphorus into the oxidation chamber, the amount of air introduced is 0.3 times the amount of air required for yellow phosphorus combustion theory, oxidation reaction occurs, crude product A is obtained, and the outlet temperature is 620°C;

[0059] ...

Embodiment 2

[0067] Preparation process is identical with embodiment 1, only impurity remover is different;

[0068] Described impurity remover is ferric tartrate / acid activated carbon;

[0069] The preparation method of the impurity remover is to add activated carbon to 0.2mol / L ferric nitrate aqueous solution, 300W / 40kHz ultrasonic for 30 minutes, add tartaric acid, adjust the pH value to 2.0, stir at 400rpm for 2 hours after the adjustment is completed, and pass through a 500-mesh sieve , the obtained solid was washed once with 1.5 times the volume of ferric nitrate aqueous solution, and dried at 100 ° C to obtain;

[0070] The amount of activated carbon added per liter of ferric nitrate aqueous solution is 60 mg.

Embodiment 3

[0072] Preparation process is identical with embodiment 1, only impurity remover is different;

[0073] Described impurity remover is lanthanum tartrate / acid activated carbon;

[0074] The preparation method of the impurity remover is to add activated carbon to 0.2mol / L lanthanum nitrate aqueous solution, 300W / 40kHz ultrasonic for 30 minutes, add tartaric acid, adjust the pH value to 2.0, stir at 400rpm for 2 hours after the adjustment is completed, and pass through a 500-mesh sieve , the obtained solid was washed once with water of 1.5 times the volume of the lanthanum nitrate aqueous solution, and dried at 100°C to obtain it;

[0075] The amount of activated carbon added per liter of lanthanum nitrate aqueous solution is 60 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com