Desulfurization-sterilization-corrosion inhibition integrated treating agent and preparation method thereof

A treatment agent and corrosion inhibition technology, applied in the field of sulfur removal-sterilization-corrosion inhibition integrated treatment agent and its preparation, can solve the problems of secondary pollution of oilfields, increase oilfield production and operation load, etc. Good corrosion effect and wide purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

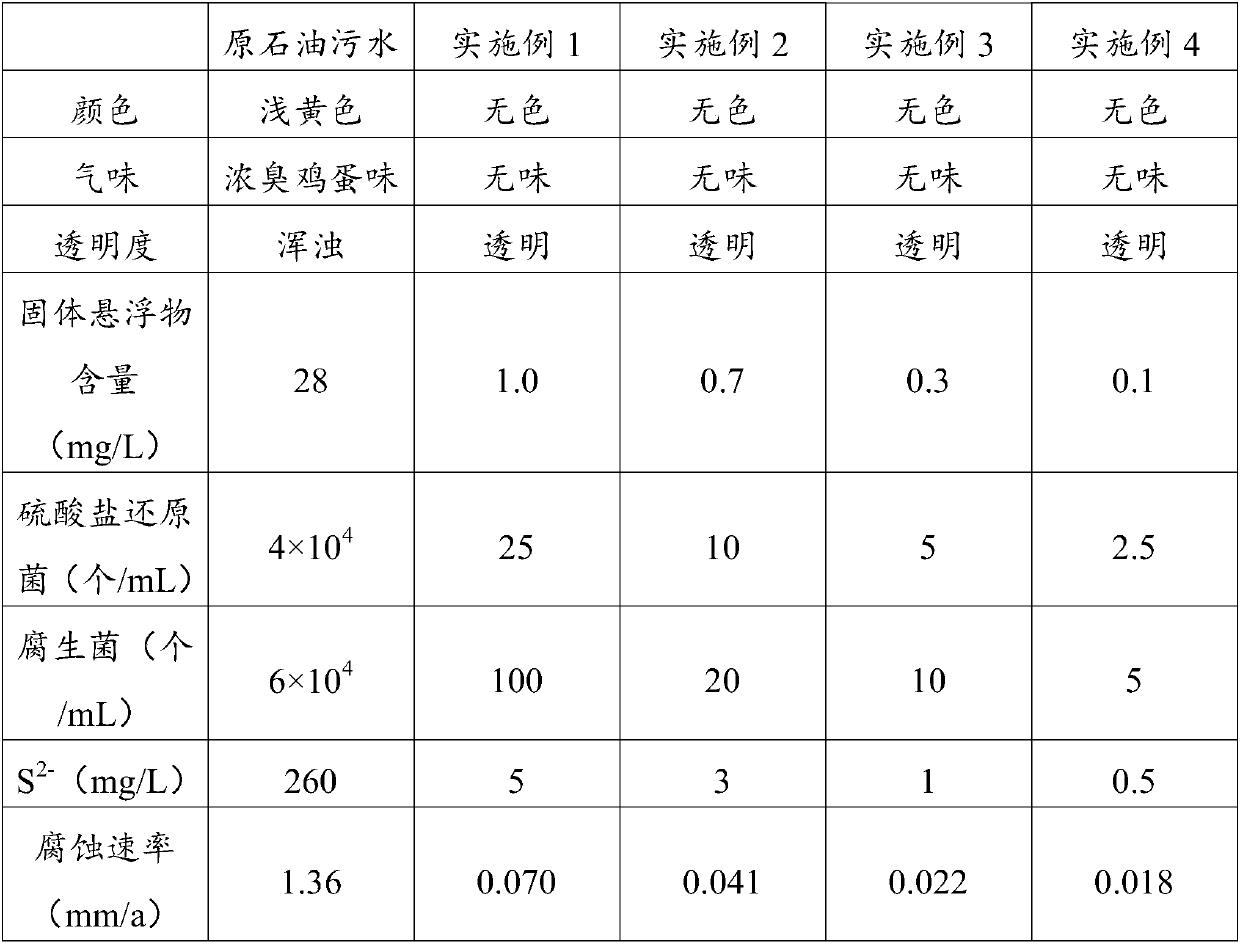

Examples

Embodiment 1

[0033] The present invention provides an integrated treatment agent for sulfur removal-sterilization-corrosion inhibition, which comprises the following components in weight percent:

[0034] Diallyl sulfide and diallyl thiosulfonate 25%,

[0035] Organic amines: polyethylene polyamine, diethylene diamine and triethylene tetramine 50%,

[0036] Formaldehyde 5%,

[0037] Cationic polyacrylamide and dimethylformamide 10%,

[0038] Alcohol 8%,

[0039] The remainder is water;

[0040] The molecular weight of the cationic polyacrylamide is 3-5 million;

[0041] The diallyl sulfide is diallyl trisulfide.

[0042] The preparation method of the described desulfurization-sterilization-corrosion inhibition integrated treatment agent comprises the following steps:

[0043] (1) Add the organic amine to the reaction kettle, stir and heat up to 65°C, then slowly add formaldehyde dropwise to the reaction kettle, after the dropwise addition, control the temperature at 75°C, and the rea...

Embodiment 2

[0048] The present invention provides an integrated treatment agent for sulfur removal-sterilization-corrosion inhibition, which comprises the following components in weight percent:

[0049] Diallyl sulfide and diallyl thiosulfonate 20%,

[0050] Organic amines: polyethylene polyamine, diethylene diamine and triethylene tetramine 40%,

[0051] Formaldehyde 10%,

[0052] Cationic polyacrylamide and dimethylformamide 5%,

[0053] Hydrophobically modified chitosan 10%,

[0054] Alcohol 5%,

[0055] The remainder is water;

[0056] The molecular weight of the cationic polyacrylamide is 3-5 million;

[0057] The diallyl sulfide is diallyl trisulfide and diallyl disulfide in a molar ratio of 3:1.

[0058] The preparation method of the described desulfurization-sterilization-corrosion inhibition integrated treatment agent comprises the following steps:

[0059] (1) Add the organic amine to the reaction kettle, stir and raise the temperature to 68°C, then slowly add formaldehy...

Embodiment 3

[0064] The present invention provides an integrated treatment agent for sulfur removal-sterilization-corrosion inhibition, which comprises the following components in weight percent:

[0065] Diallyl sulfide and diallyl thiosulfonate 30%,

[0066] Organic amines: polyethylene polyamine, diethylene diamine and triethylene tetramine 42%,

[0067] Formaldehyde 6%,

[0068] Cationic polyacrylamide 2% and dimethylformamide 3%,

[0069] Hydrophobically modified chitosan 8%,

[0070] Alcohol 6%,

[0071] The remainder is water;

[0072] The molecular weight of the cationic polyacrylamide is 3-5 million;

[0073] The diallyl sulfide is diallyl trisulfide and diallyl disulfide in a molar ratio of 2:1;

[0074] The weight ratio of the hydrophobically modified chitosan to the cationic polyacrylamide is 4:1.

[0075] The preparation method of the described desulfurization-sterilization-corrosion inhibition integrated treatment agent comprises the following steps:

[0076] (1) Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com