A Load Adaptive Constant Current Generating Circuit

A circuit generation and self-adaptive technology, applied in the direction of adjusting electrical variables, instruments, control/regulation systems, etc., can solve problems such as no over-current power-off protection, load or instrument damage, output current exceeding the limit current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

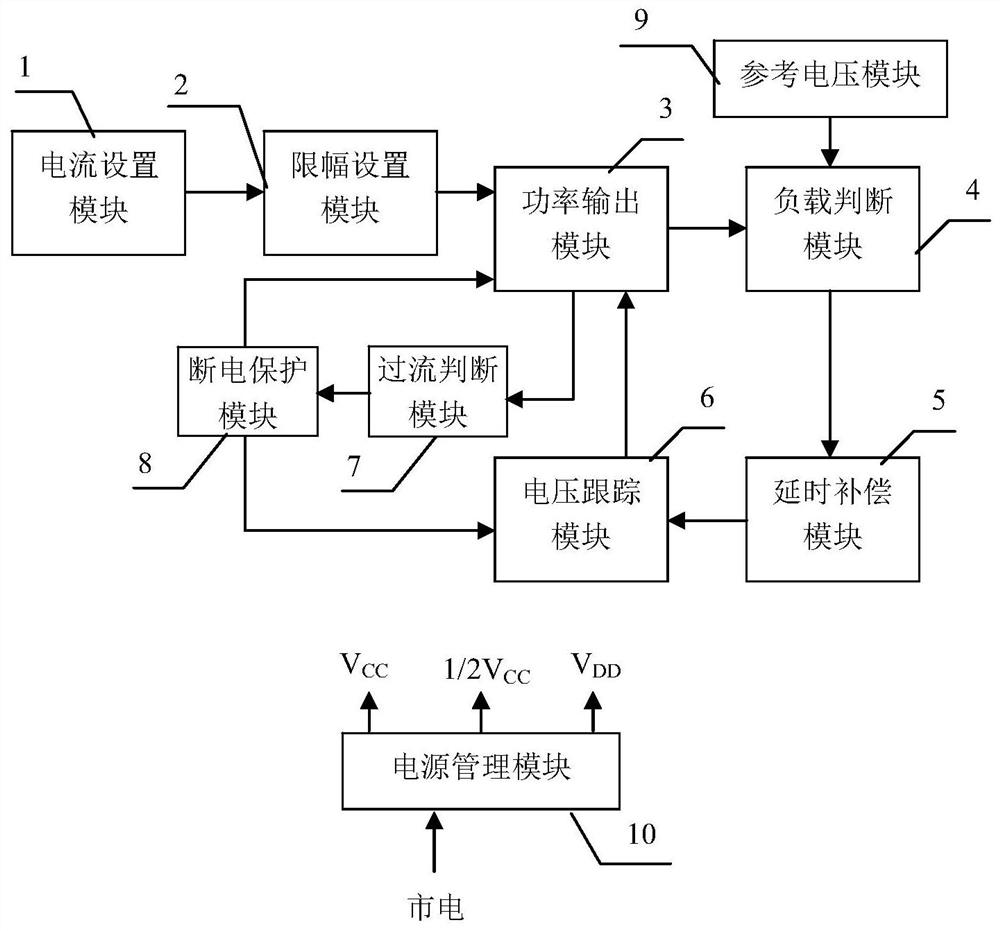

[0033] Embodiment 1 Overall structure of the present invention

[0034] Overall structure of the present invention is as figure 1 As shown, current setting module 1, limiter setting module 2, power output module 3, load judgment module 4, delay compensation module 5, voltage tracking module 6, overcurrent judgment module 7, power-off protection module 8, reference voltage module 9 and a power management module 10; wherein, the current setting module 1 is connected to the limit setting module 2, the limit setting module 2 is connected to the power output module 3, and the power output module 3 is connected to the load judgment module 4 and the overcurrent judgment module 7, The reference voltage module 9 is connected to the load judgment module 4, the load judgment module 4 is connected to the delay compensation module 5, the delay compensation module 5 is connected to the voltage tracking module 6, the voltage tracking module 6 is connected to the power output module 3, and th...

Embodiment 2

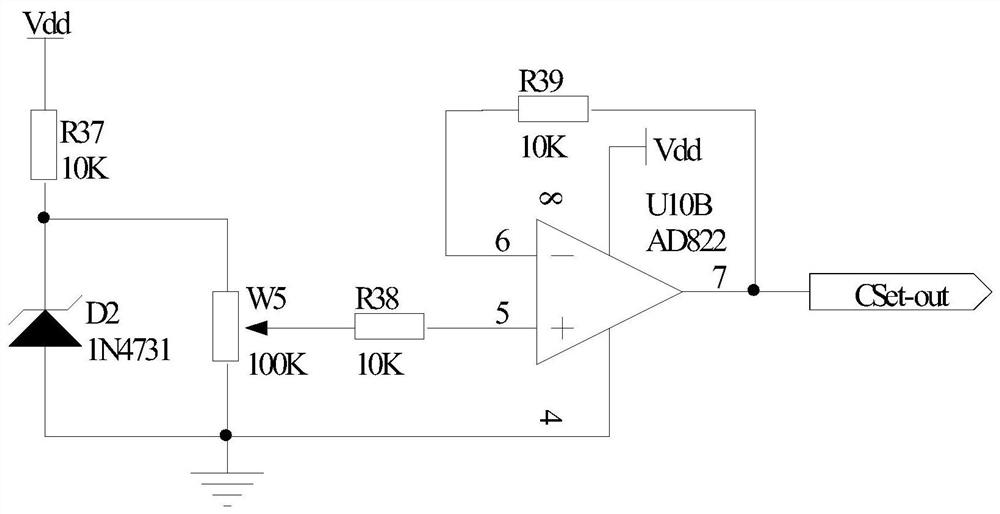

[0035] Embodiment 2 The current setting module of the present invention

[0036] The current setting module 1 of the present invention belongs to conventional technology, can be designed according to specific requirements, and can also adopt the structure provided by this embodiment, such as figure 2 As shown, one end of the resistor R37 is connected to the power supply Vdd, the other end is connected to the cathode of the Zener diode D2 and a fixed end of the sliding rheostat W5, the anode of the Zener diode D2 is grounded, the other fixed end of the sliding rheostat W5 is grounded, and the resistor R38 One end is connected to the sliding wire end of the sliding rheostat W5, the other end is connected to the non-inverting input end of the op amp U10B, the inverting input end of the op amp U10B is connected to one end of the resistor R39, and the other end of the resistor R39 is connected to the output end of the op amp U10B, and used as The output terminal of the current set...

Embodiment 3

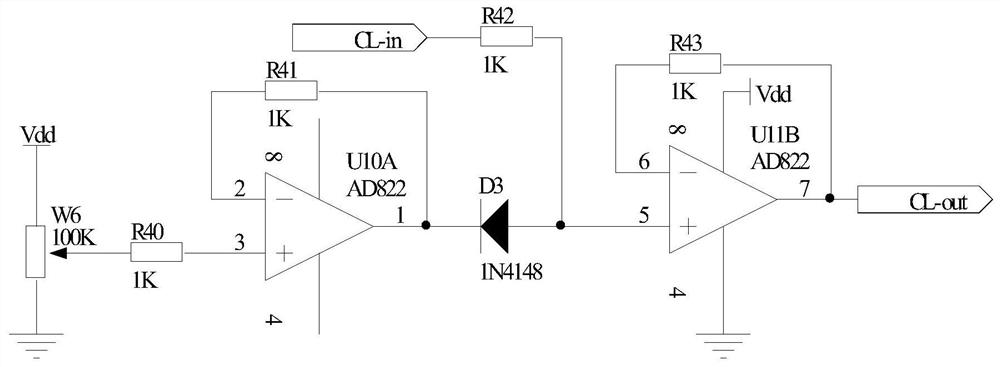

[0038] Embodiment 3 Limit setting module of the present invention

[0039] Limiter setting module 2 of the present invention belongs to conventional technology, can be designed according to specific requirements, and the structure provided by this embodiment can also be adopted, such as image 3 As shown, one end of the resistor R42 is used as the input end of the limiter setting module 2, which is recorded as port CL-in, and the other end is connected to the non-inverting input end of the operational amplifier U11B and the positive pole of the diode D3, and the negative pole of the diode D3 is connected to the output of the operational amplifier U10A end and one end of the resistor R41, the other end of the resistor R41 is connected to the inverting input end of the operational amplifier U10A, the non-inverting input end of the operational amplifier U10A is connected to one end of the resistor R40, and the other end of the resistor R40 is connected to the sliding end of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com