Lactobacillus plantarum and method for mixed fermentation of sour plesiopidae

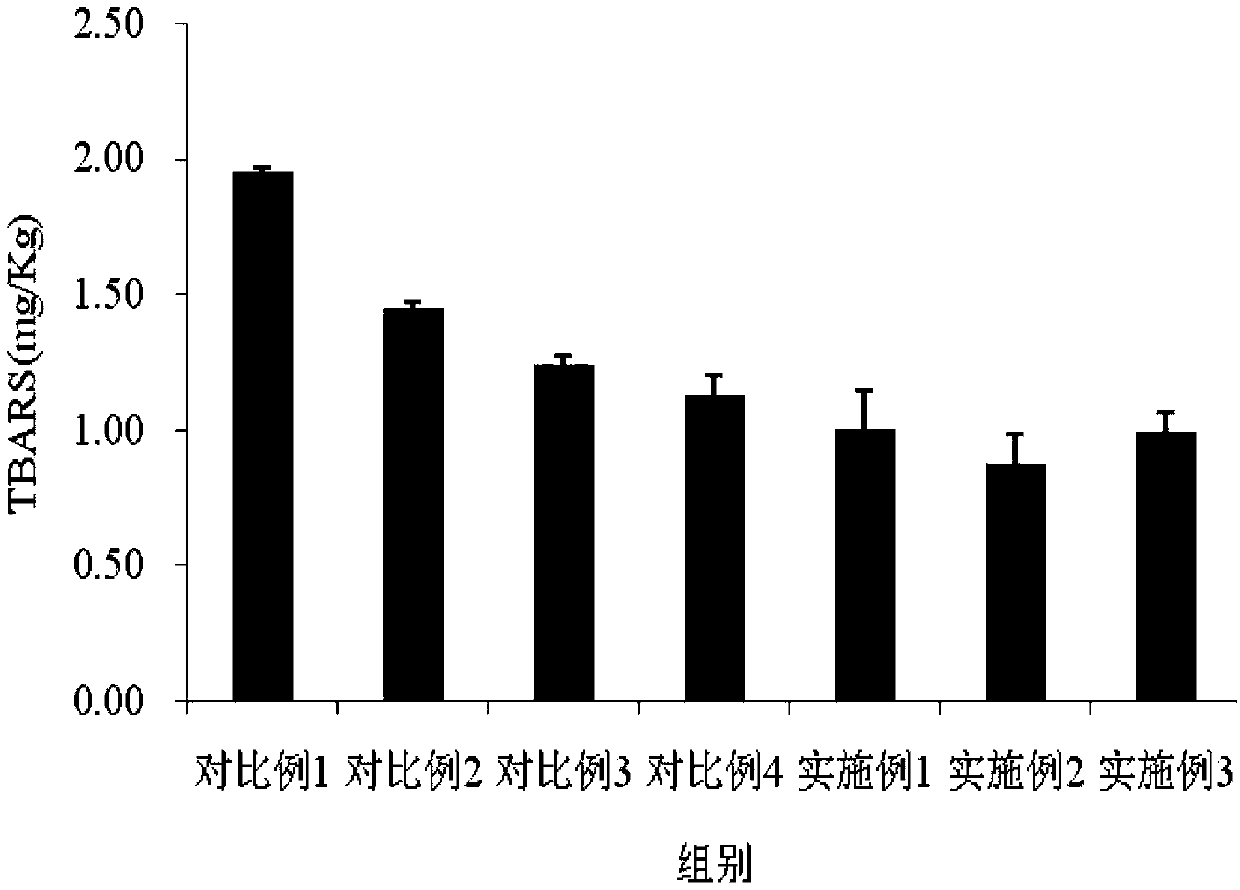

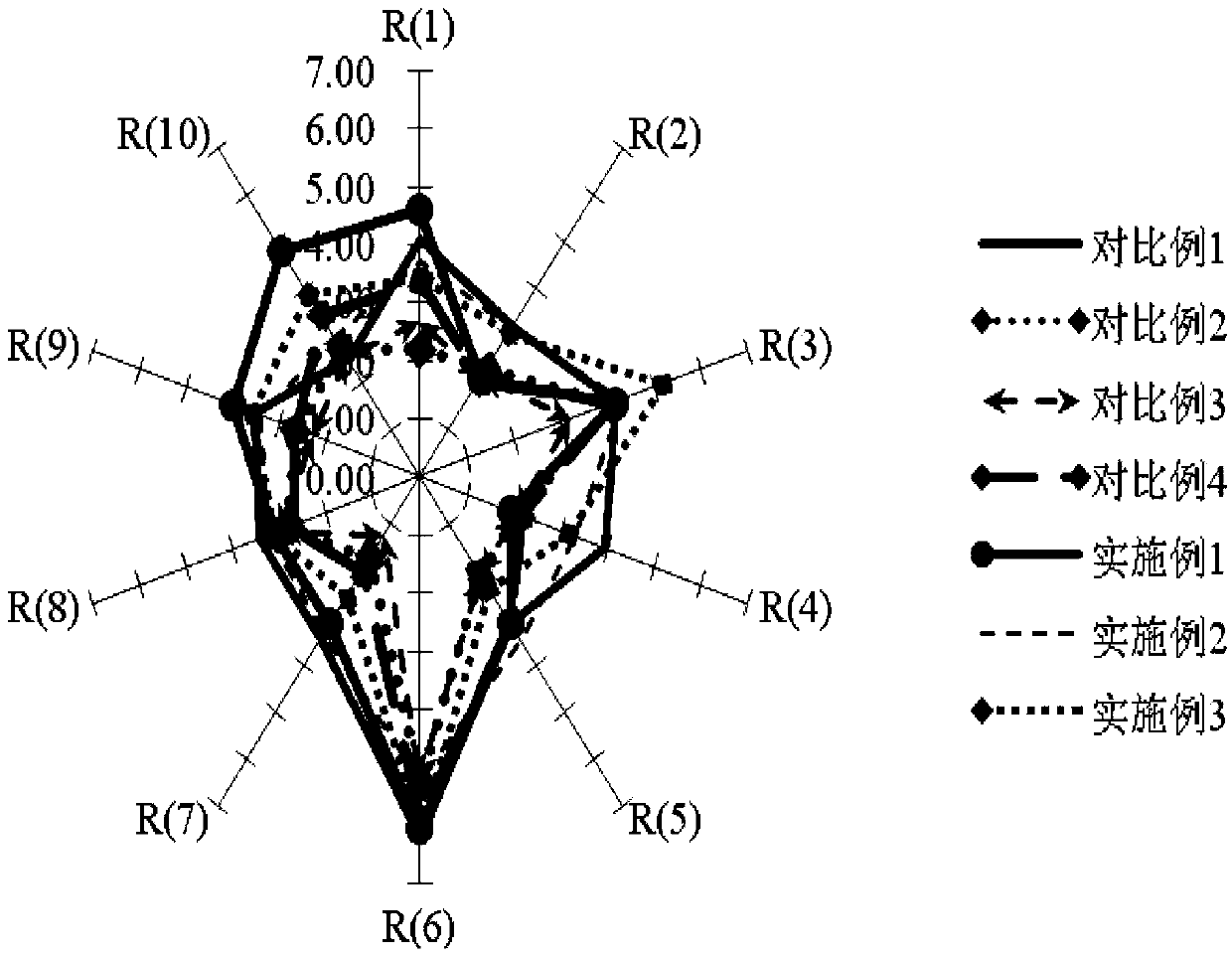

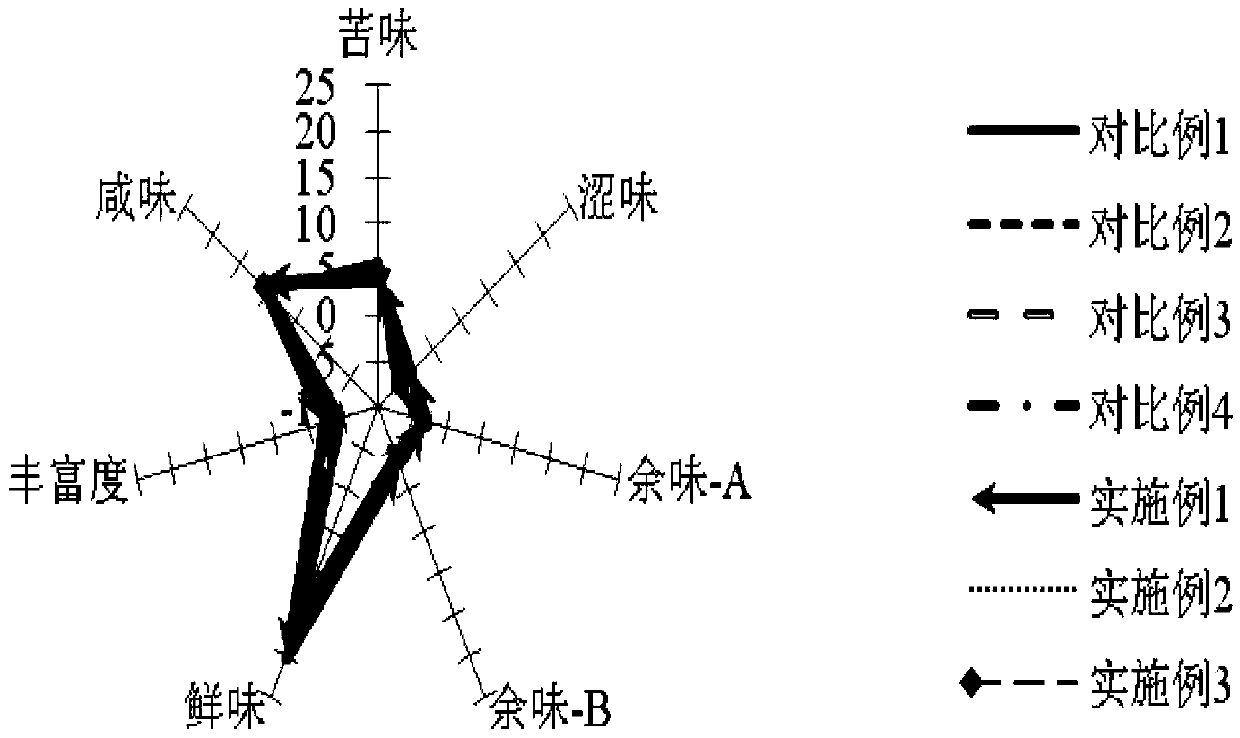

A technology of Lactobacillus plantarum and mixed fermentation, which is applied in the field of food processing, can solve the problems of long release time of endogenous enzymes and slow flavor action, and achieve the effects of improving flavor and taste, inhibiting fat oxidation, and reducing the content of biogenic amines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for mixing fermented sour bream with lactobacillus plantarum comprises the following steps:

[0031] S1. Raw material pretreatment: remove the scales, heads, tails, and viscera of the live carp, and cut the resulting fish body into small pieces for later use, totaling 5Kg;

[0032] S2. Fermentation: Mix the fish nuggets obtained in step S1, rice noodles and salt in a weight ratio of 90:50:2, and add 10 6 Mix CFU / mL Lactobacillus plantarum 24 bacteria liquid and 15000U / mL papain enzyme liquid evenly; put it into a tank for mixed fermentation, seal the top layer with rice flour, tighten the lid, and leave it sealed at 20°C for 30 days to obtain sour bream fish; Wherein, the rice noodles are powders ground from fried rice, and the added amount of the plantarum Lactobacillus 24 bacterial solution is 0.0006mL / g 鱼块 (Totally add 3 mL of Lactobacillus plantarum 24 bacterial liquid); the amount of papain liquid added is 0.0066 mL / g 鱼块 , (add papain solution 33mL alt...

Embodiment 2

[0036] The method for mixed fermentation of sour bream with lactobacillus plantarum comprises the following steps:

[0037]S1. Raw material pretreatment: remove scales, heads, tails and viscera of live grass carp, and cut the fish body into small pieces for later use, totaling 5Kg;

[0038] S2. Fermentation: Mix the fish nuggets obtained in step S1, rice noodles and salt in a weight ratio of 100:65:3, and add 10 7 CFU / mL Lactobacillus plantarum 24 bacteria liquid and 10000U / mL papain enzyme liquid were stirred evenly; put them into a tank for mixed fermentation, sealed the top layer with rice flour, tightened the lid, and kept it sealed at 25°C for 28 days to obtain sour bream fish; Wherein, the rice noodles are powders ground from fried rice, and the addition amount of the plantarum Lactobacillus 24 bacterium solution is 0.006mL / g 鱼块 (Add 30mL of Lactobacillus plantarum 24 bacteria solution in total); the amount of papain solution added is 0.005mL / g 鱼块 , (add papain solutio...

Embodiment 3

[0042] The method for mixing fermented sour bream with lactobacillus plantarum comprises the following steps:

[0043] S1. Raw material pretreatment: remove the scales, heads, tails and viscera of the live bighead carp, and cut the resulting fish body into small pieces for later use, totaling 5Kg;

[0044] S2. Fermentation: Mix the fish nuggets obtained in step S1, rice noodles and salt in a weight ratio of 115:70:4, and add 10 8 CFU / mL Lactobacillus plantarum 24 bacteria liquid and 20000U / mL papain enzyme liquid are stirred evenly; put into a tank for mixed fermentation, seal the top layer with rice flour, tighten the lid, and leave it sealed at 20°C for 20 days to obtain sour bream fish; Wherein, the rice flour is ground into fried rice, and the addition amount of the plantarum lactobacillus 24 bacterium liquid is 0.025mL / g 鱼块 (Add 300mL of Lactobacillus plantarum 24 bacteria solution in total); the amount of papain solution added is 0.025mL / g 鱼块 , (add papain liquid 125mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com