Treatment device for organic contaminant industrial waste gas

A technology for organic pollutants and industrial waste gas, which is applied in gas treatment, membrane technology, and separation of dispersed particles. It can solve problems such as insecure safety, high energy consumption, and inability to solve regeneration problems, and achieves stable filtration efficiency and effects. Wide range of spray purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

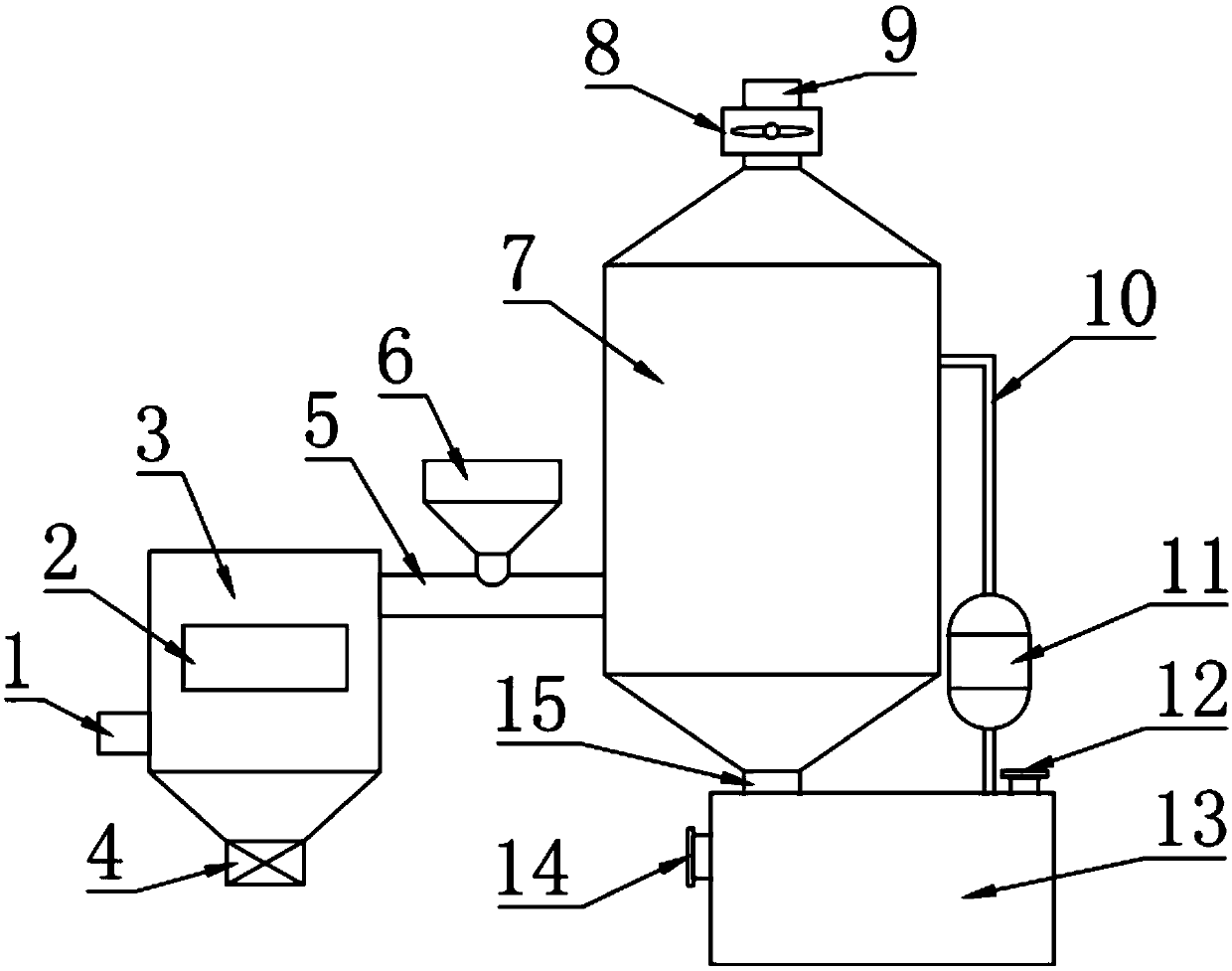

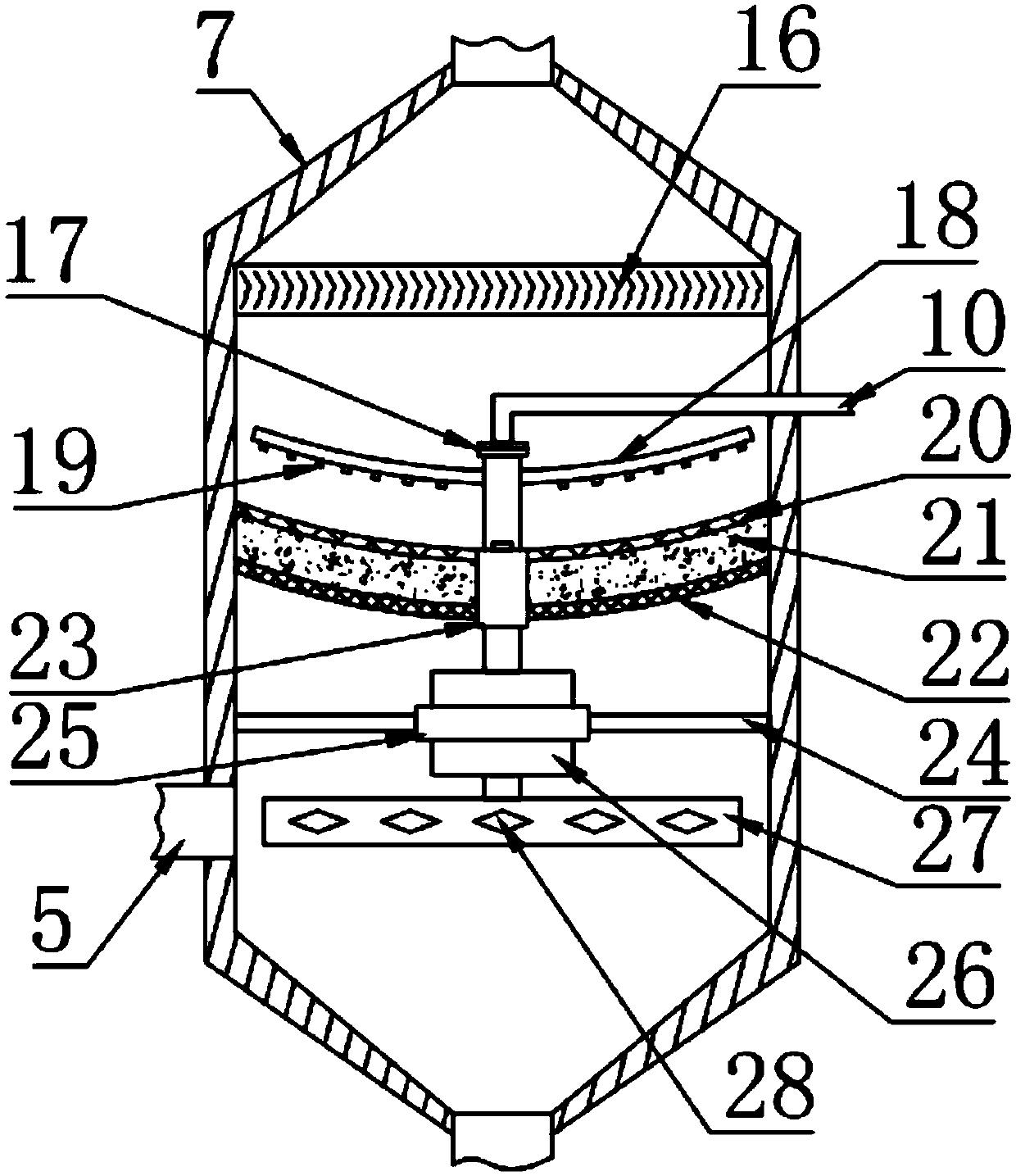

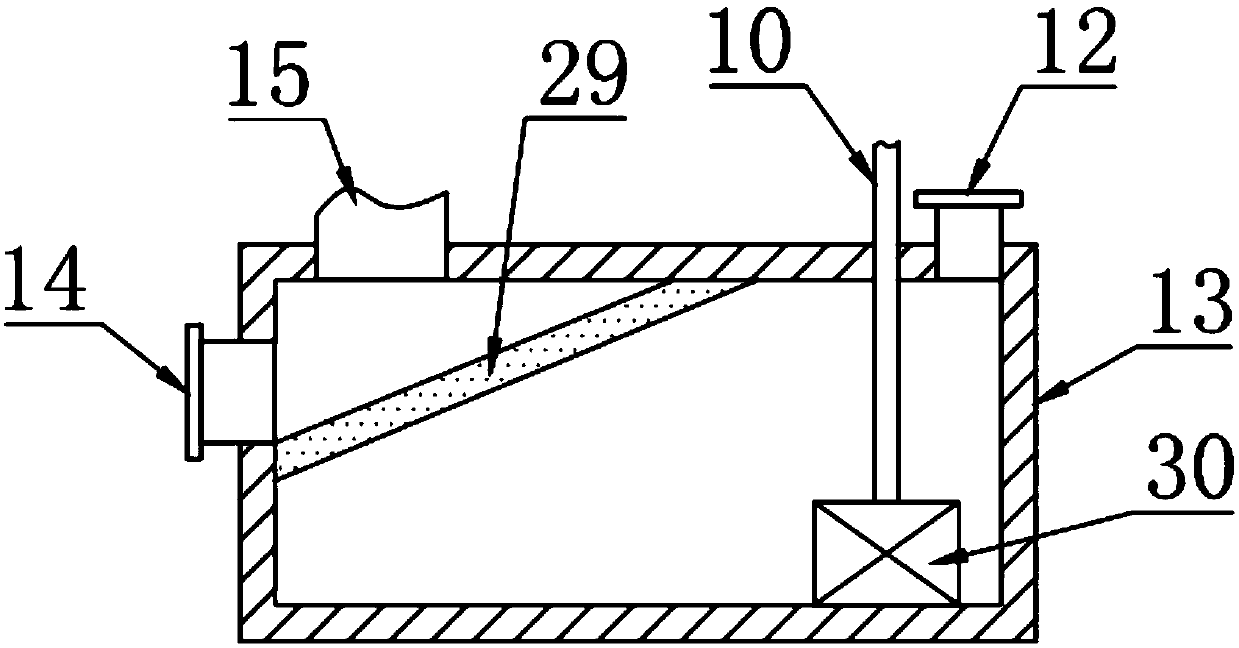

[0031] see Figure 1~4 , in the embodiment of the present invention, an industrial waste gas treatment device for organic pollutants, comprising a pretreatment box 3, a filter 7 and a liquid storage tank 13, the lower part of the pretreatment box 3 is provided with an air inlet 1, and the pretreatment box 3 is provided with an ash outlet 4, and a high-voltage pulse discharger 2 is also provided in the pretreatment box 3. The top of the pretreatment box 3 is connected to the filter 7 through the air outlet pipe 5, and the air outlet pipe 5 is connected to a polyacid The top of the hopper 6, the filter 7 is provided with an exhaust pipe 9, the exhaust pipe 9 is provided with an induced draft fan 8, and the bottom end of the filter 7 is connected to a liquid storage tank 13 through a liquid discharge pipe 15.

[0032] Such as figure 2 As shown, the inner lower part of the filter 7 is supported and fixed with a motor holder 25 by a support frame 24, and a double-axis extension m...

Embodiment 2

[0036] An industrial waste gas treatment system, comprising the organic pollutant industrial waste gas treatment device described in Embodiment 1.

[0037] In this organic pollutant industrial waste gas treatment device, the waste gas containing acid mist and organic pollutants first enters the pretreatment box 3 through the air inlet 1, and the gas passes through the pretreatment box 3 and the filter 7 in turn under the action of the induced draft fan 8, and the pretreatment The high-voltage pulse discharger 2 in the treatment box 3 implements high-voltage pulse discharge to generate ozone, ultrasound and ultraviolet radiation, and oxidizes and decomposes organic pollutants in the waste gas. Exhaust; then the exhaust gas enters the filter 7 along the outlet pipe 5, and at the same time, polyacrylamide powder is added to the exhaust gas of the outlet pipe 5 from the polyacid hopper 6; the exhaust gas mixed with polyacrylamide powder enters the filter 7 and passes through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com