Preparation method of ZnO/Zinc-indium-sulfur nanoheterojunction

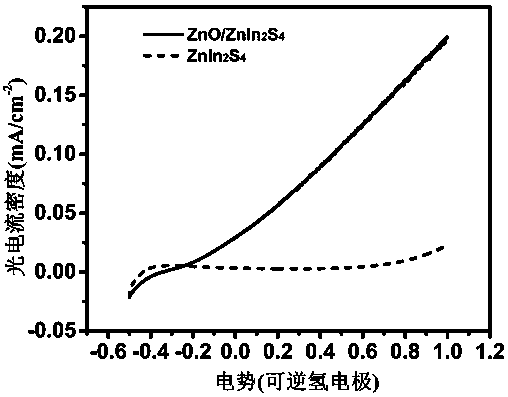

A zinc-indium-sulfur nano-heterojunction technology, which is applied in chemical instruments and methods, hydrogen production, hydrogen/synthesis gas production, etc., can solve the problems of low repeatability, complex preparation process of nano-film catalysts, effective separation of catalysts and Recycling problems and other problems, to achieve high repeatability, increase the absorption rate of visible light, and improve the effect of photocurrent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

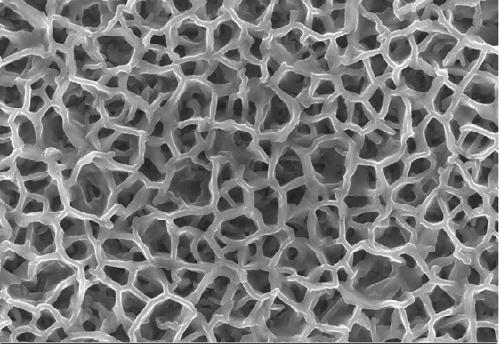

[0024] A preparation method of ZnO / zinc indium sulfur nano-heterojunction, the molecular formula of zinc indium sulfur is ZnIn 2 S 4 , combining atomic layer deposition and hydrothermal methods to achieve ZnIn on fluorine-doped tin oxide (FTO) substrates 2 S 4 In situ growth of nanosheet array structure, followed by atomic layer deposition (ALD) technology to deposit a certain thickness of ZnO thin film to construct ZnO / ZnIn with high-efficiency visible light catalytic activity 2 S 4 A nano-heterojunction structure comprising the following steps:

[0025] (1) On the surface of the cleaned FTO conductive glass, a 100 nm ZnS seed layer was deposited by ALD technology at a deposition temperature of 150 °C;

[0026] (2) Mix zinc nitrate, indium chloride, and thioacetamide into the inner tank of the reactor according to the molar ratio of 1:3:4, then add 40 ml of ethylene glycol, and then stir or ultrasonically dissolve to form A homogeneous solution with an indium salt concen...

Embodiment 2

[0030] A ZnO / ZnIn 2 S 4 The preparation method and application of the nano-heterojunction, comprising the following steps:

[0031] (1) On the surface of the cleaned FTO conductive glass, a 50 nm ZnS seed layer was deposited by ALD technology at a deposition temperature of 200 °C;

[0032] (2) Mix zinc sulfate, indium nitrate, and thioacetamide into the inner tank of the reactor according to the molar ratio of 1:2:4, then add 40 ml of ethylene glycol, and then stir or ultrasonically dissolve to make indium A homogeneous solution with a salt concentration of 0.3M; the reaction temperature was maintained at 180°C, and the reaction time was 6h.

[0033] (3) Take out the sample after the reaction in (2), wash and dry it, and then deposit a 100nm ZnO nano film on its surface by ALD technology to obtain ZnO / ZnIn 2 S 4 nanoheterojunction.

Embodiment 3

[0035] A ZnO / ZnIn 2 S 4 The preparation method and application of the nano-heterojunction, comprising the following steps:

[0036] (1) On the surface of the cleaned FTO conductive glass, a 200 nm ZnS seed layer was deposited by ALD technology at a deposition temperature of 250 °C;

[0037] (2) Mix zinc chloride, indium acetate, and thiourea into the inner tank of the reactor according to the molar ratio of 1:4:4, then add 40ml of ethylene glycol, and then stir or ultrasonically dissolve to make the indium salt concentration It is a 0.4M homogeneous solution; the reaction temperature is maintained at 220°C, and the reaction time is 2h.

[0038] (3) Take out the sample after the reaction in (2), wash and dry it, and then deposit a 150nm ZnO nano film on its surface by ALD technology to obtain ZnO / ZnIn 2 S 4 nanoheterojunction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com