A kind of probe modified polyquaternium composite material and its preparation method and application

A polyquaternary ammonium salt and composite material technology, which is applied in the direction of analysis by chemical reaction of materials, chemical instruments and methods, and material analysis by observing the impact on chemical indicators, etc., can solve the problem of limited binding capacity of target metal ions. , The number of materials per unit surface is low, and the composite materials are difficult to pure water, so as to achieve the effects of green environmental protection, low cost and simple equipment in the detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

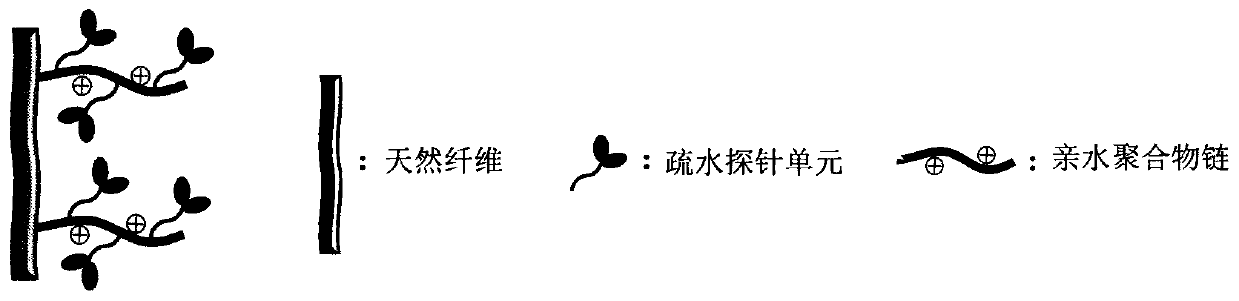

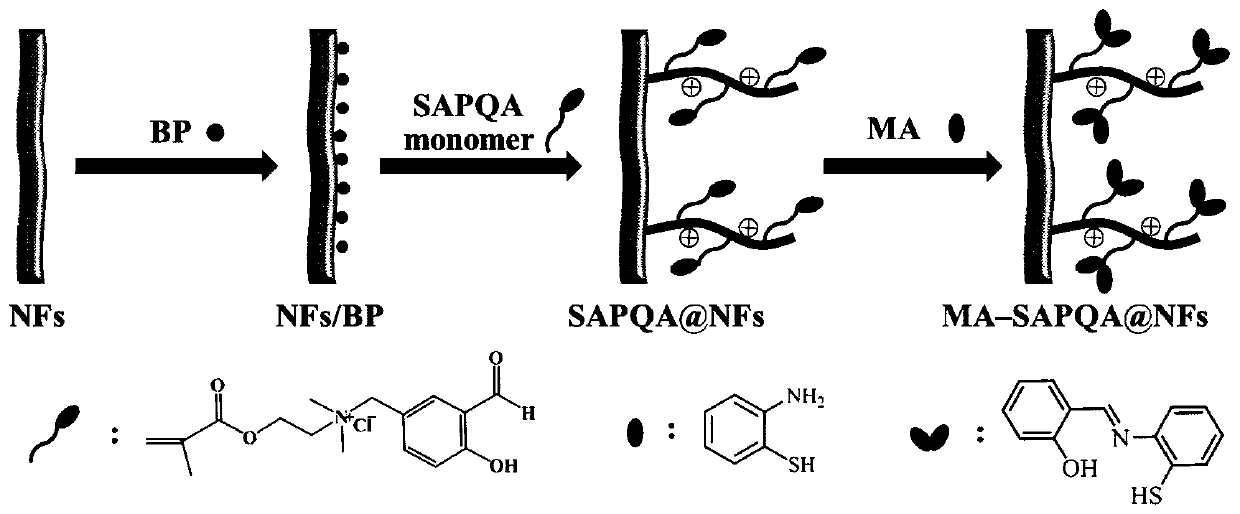

[0043] Synthesis of natural fiber / benzophenone complex (NFs / BP): Weigh 100mg of NFs and place in 20mL of ethanol solution containing 0.1% BP, oscillate ultrasonically for 5min, rotary evaporate, and vacuum dry at 70°C to obtain NFs / BP;

[0044] Synthetic salicylaldehyde polyquaternium monomer / natural fiber composite (SAPQA@NFs): Weigh 200mg NFs / BP and 200mg SAPQA into 2mL deionized water, fill with N 2 30min, under the condition of 50℃, irradiate with ultraviolet lamp for 1h, filter with suction, wash with deionized water and ethanol, and dry under vacuum at 70℃ to obtain SAPQA@NFs;

[0045] Synthetic structure such as figure 1 The probe-modified polyquaternium composite material MA-SAPQA@NFs shown: Weigh 200mgSAPQA@NFs and 20mg MA in 20mL of absolute ethanol, heat to reflux at 85°C, react for 8h, cool to room temperature, and filter with suction , and washed with absolute ethanol, and dried in vacuum to obtain the probe-modified polyquaternium composite material MA-SAPQA@NF...

Embodiment 2

[0074] Synthesis of NFs / BP: Weigh 60 mg of NFs and place in 15 mL of ethanol solution containing 0.1% BP, sonicate for 5 min, rotary evaporate, and vacuum-dry at 70°C to obtain NFs / BP;

[0075] Synthesis of SAPQA@NFs: Weigh 80mg NFs / BP and 110mg SAPQA into 4mL deionized water, fill with N 2 30min, under the condition of 45°C, irradiate with ultraviolet light for 45min, filter with suction, wash with deionized water and ethanol, and dry in vacuum at 70°C to obtain SAPQA@NFs;

[0076] Synthesis of probe-modified polyquaternium composite material MA-SAPQA@NFs: Weigh 120mg SAPQA@NFs and 30mg MA into 5mL absolute ethanol, heat to reflux at 80°C, react for 7h, cool to room temperature, and filter with suction. And washed with absolute ethanol, vacuum-dried to obtain the probe-modified polyquaternium composite material MA-SAPQA@NFs.

Embodiment 3

[0078] Synthesis of NFs / BP: Weigh 1 g of NFs and place in 100 mL of ethanol solution containing 0.1% BP, sonicate for 5 min, rotary evaporate, and vacuum dry at 70°C to obtain NFs / BP;

[0079] Synthesis of SAPQA@NFs: Weigh 1.1g NFs / BP and 1.2g SAPQA into 10mL deionized water, fill with N 2 30min, under the condition of 55°C, irradiate with ultraviolet light for 75min, filter with suction, wash with deionized water and ethanol, and dry in vacuum at 70°C to obtain SAPQA@NFs;

[0080] Synthesis of probe-modified polyquaternium composite material MA-SAPQA@NFs: Weigh 1.3g SAPQA@NFs and 0.4g MA in 60mL absolute ethanol, heat to reflux at 78°C, react for 10h, cool to room temperature, pump Filtered, washed with absolute ethanol, and dried in vacuum to obtain the probe-modified polyquaternium composite material MA-SAPQA@NFs.

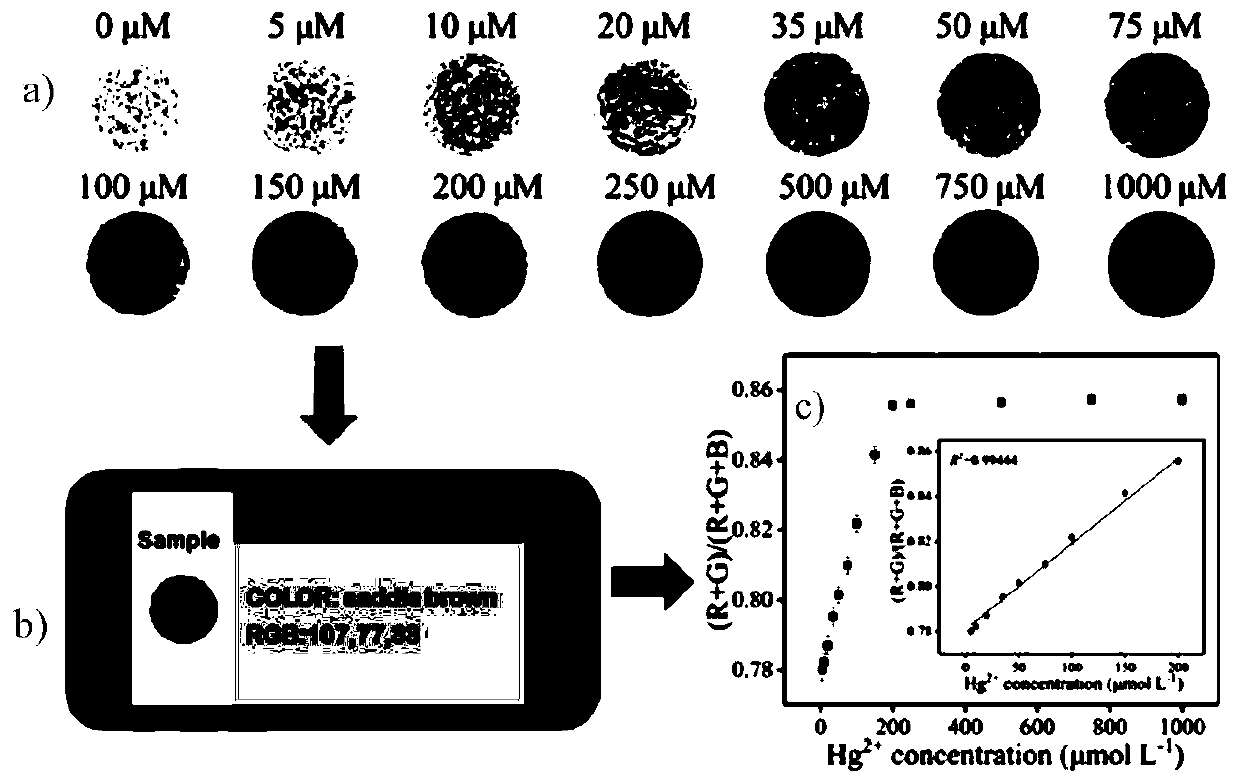

[0081] The probe-modified polyquaternary ammonium salt composite material MA-SAPQA@NFs prepared by the present invention improves the water solubility of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com