Novel local acidic electro-Fenton water treatment device and method

An acidic and partial technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the problems of increasing wastewater treatment costs, increasing water treatment costs, etc., to reduce sludge production and facilitate comprehensive treatment Process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

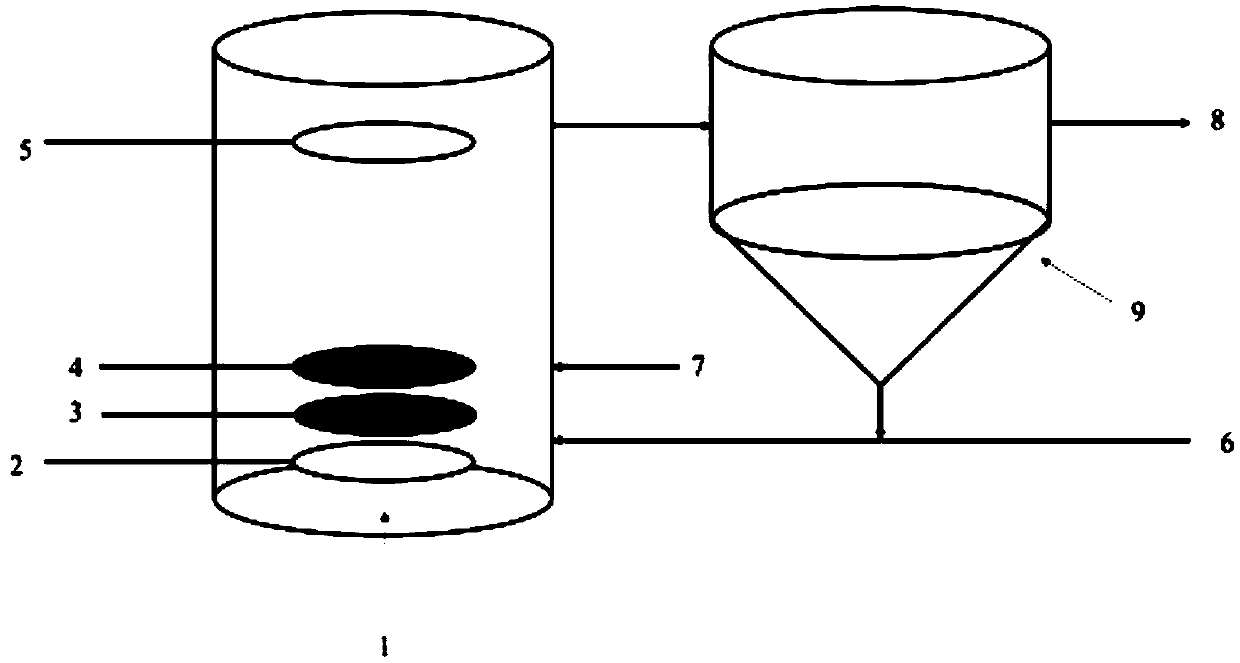

[0043] The simulated wastewater is 1L of 10mg / L rhodamine B (RhB) solution, using figure 1 The processing device; wherein:

[0044] Electrode diameter is 50mm;

[0045] The distance between the oxygen evolution electrode and the iron electrode is 2cm, and the current between the iron electrode and the graphite electrode is set to 5mA / cm 2;

[0046] Add 1mL H 2 o 2 solution, 20mM anhydrous sodium sulfate as electrolyte.

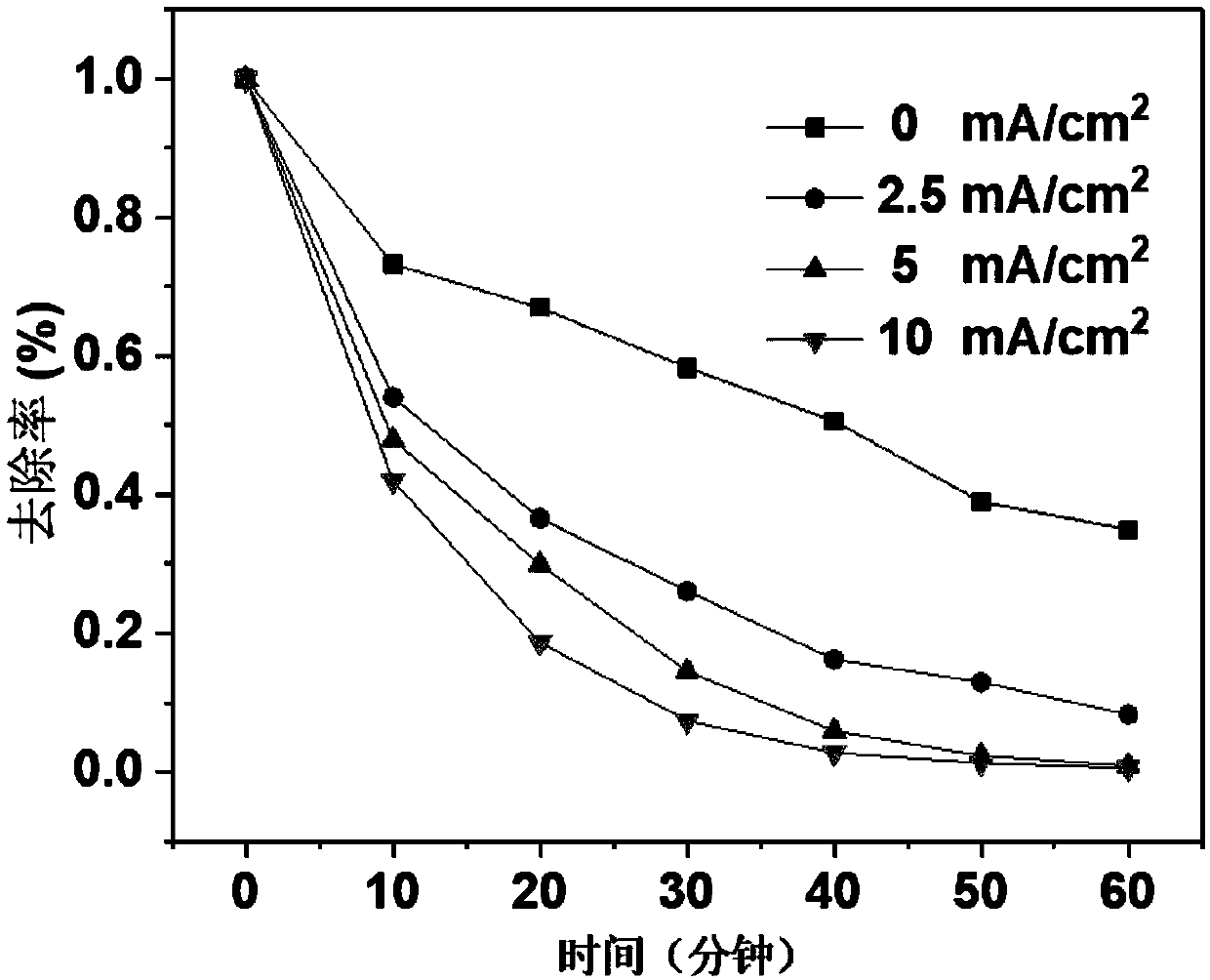

[0047] By changing the current density between the oxygen evolution electrode and the hydrogen evolution electrode, the influence of the current density on the degradation efficiency of the electro-Fenton system was investigated.

[0048] Such as figure 2 As shown, when the oxygen evolution electrode does not pass current, RhB degrades 66% after 1 hour of reaction; when the current density of the oxygen evolution electrode is 2.5mA / cm 2 , RhB was degraded by 92% after 1h of reaction; when the current density continued to increase to 5mA / cm 2 and 10mA / ...

Embodiment 2

[0051] The simulated wastewater is 1L of 10mg / L rhodamine B (RhB) solution, using figure 1 the device. in:

[0052] Electrode diameter is 50mm;

[0053] The current between the iron electrode and the graphite electrode was set at 5mA / cm 2 , the current density at the oxygen evolution anode and hydrogen evolution electrode is 5mA / cm 2 , add 1mL H 2 o 2 solution, 20mM anhydrous sodium sulfate as electrolyte.

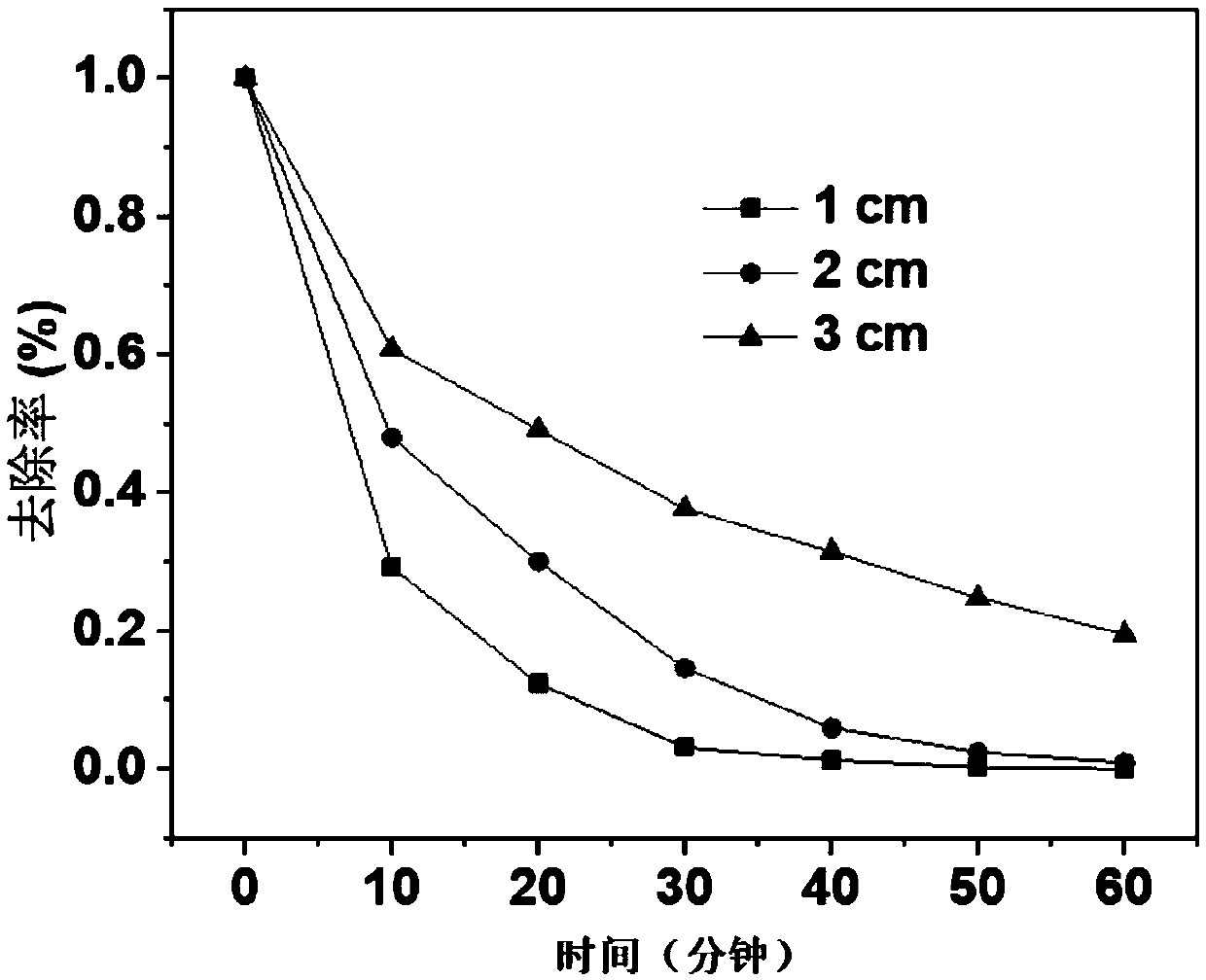

[0054] By adjusting the plate distance between the oxygen evolution electrode and the iron electrode, the effect of the plate distance on the degradation efficiency of the electro-Fenton system was investigated.

[0055] Such as image 3 As shown, when the distance between the oxygen evolution electrode and the iron electrode is 3 cm, after 1 hour of reaction, the degradation efficiency of the electro-Fenton system to RhB is 80%; when the distance between the oxygen evolution electrode and the iron electrode is When it was reduced to 2cm, RhB was almost completely ...

Embodiment 3

[0058] The simulated wastewater is 1L of 10mg / L rhodamine B (RhB) solution, using figure 1 the device. in:

[0059] Electrode diameter is 50mm;

[0060] The current between the iron electrode and the graphite electrode was set at 5mA / cm 2 , the current density of the oxygen evolution anode electrode and the hydrogen evolution electrode is 5mA / cm 2 , The distance between the oxygen evolution electrode and the iron electrode is 2cm, and 20mM anhydrous sodium sulfate is used as the electrolyte.

[0061] By adding different concentrations of hydrogen peroxide, the influence of the concentration of hydrogen peroxide on the efficiency of electro-Fenton system to degrade wastewater was investigated.

[0062] Such as Figure 4 As shown, when the dosage of hydrogen peroxide is 0.5mL / L, the degradation efficiency of RhB is the fastest; when the dosage of hydrogen peroxide is increased to 1mL / L, the degradation efficiency of RhB is slightly decreased; continue to increase the dosage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com