Method for increasing filtering speed of filter material

A technology of filtration speed and filter material, applied in the fields of filtration treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., which can solve the problem of management workload, increased labor intensity, slower filtration speed of filter tanks, and substandard water. and other problems, to achieve the effect of reducing sludge production, easy implementation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

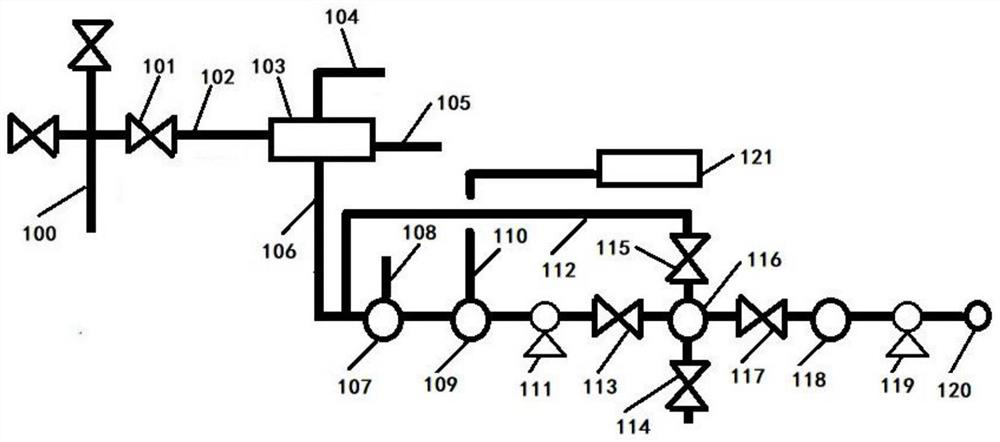

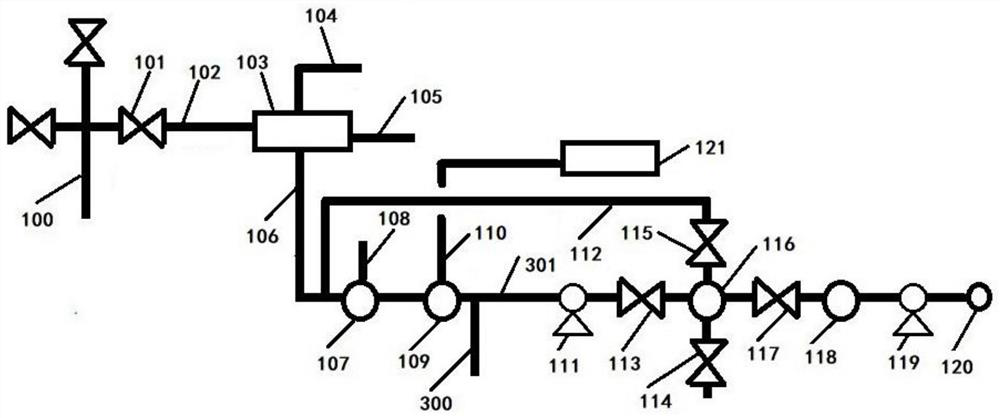

[0124] see image 3 Shown, a kind of method that improves filter material filtering speed, comprises the steps:

[0125] 1) First, add strong oxidant gas into the sewage pipeline 301 before the sewage pump 111 through the dosing pipeline 300, so as to oxidize and decompose or / and break the water-soluble polymer or / and polymer residue in the sewage, so as to reduce the sludge production, Enhance the ability of sewage to pass through the filter material;

[0126] 2) Then let the sewage containing strong oxidant gas pass through the sewage pump 111 and the sewage inlet valve 113 successively to enter the filter device 116 to continue to oxidize and decompose or / and crush the water-soluble polymer or / and polymer residue, and use the filter device 116 The filter material filters out the suspended solids and emulsified oil in the sewage, so that the sewage can be injected into the oil layer or formation after being filtered through the sewage outlet valve 117, the water injection s...

Embodiment 2

[0135] see Figure 5 Shown, repeat embodiment 1, and its difference is: in order to accelerate the speed of strong oxidant gas oxidative decomposition water-soluble polymer, in step 1), first by dosing pipeline 300, strong oxidant gas is added to the sewage before sewage pump 111 In the pipeline 301, the sewage containing the strong oxidant gas is then passed through the catalyst 500 and contacted with the catalytic packing therein, so as to accelerate the oxidative decomposition of the strong oxidant gas or / and break the water-soluble polymer or / and polymer residue in the sewage and efficiency.

[0136] Further, see Figure 6 As shown, the catalytic converter 500 includes a housing 600, a filler grid 601, a catalytic filler 604, a sewage inlet 602, and a sewage outlet 605; one end of the housing 600 is connected to the sewage inlet 602, and the other end is connected to the sewage outlet 605; A filler grid 601 is placed inside the casing 600, and holes 603 are evenly distri...

Embodiment 3

[0141] see Figure 8 As shown, repeat Example 1, the difference is: in order to strengthen the diffusion rate of strong oxidant gas, and then enhance its oxidative decomposition rate, reduce its waste, in step 1), use strong oxidant gas dosing system 800, strong oxidant gas The gas pipeline 801 adds the strong oxidant gas into the sewage pipeline 301 before the sewage pump 111; the strong oxidant gas dosing system refers to a packed tower, a spray tower, a plate tower, a bubble tower, an agitator, a static mixer, Any one of filler static mixer, bubbler or any combination of two or more.

[0142]It can be seen from the known knowledge in the art that the dissolution rate and diffusion rate of gas in water are relatively slow; taking the third joint station of Shenyang Oilfield as an example, the length of the sewage pipeline from the sewage pump to the filter tank is less than 100 meters, and the flow time of sewage in it is less than 2 minutes; ozone is difficult to decompose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com