A kind of polytetrafluoroethylene material with low coefficient of linear expansion and having adhesive property and preparation method thereof

A polytetrafluoroethylene, linear expansion coefficient technology, used in film/sheet adhesives, adhesives, films/sheets without carriers, etc., can solve the problems of plastic deformation, large expansion coefficient, non-stickiness, etc. The effect of uniform molecular weight distribution, simple synthesis process and controllable relative molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

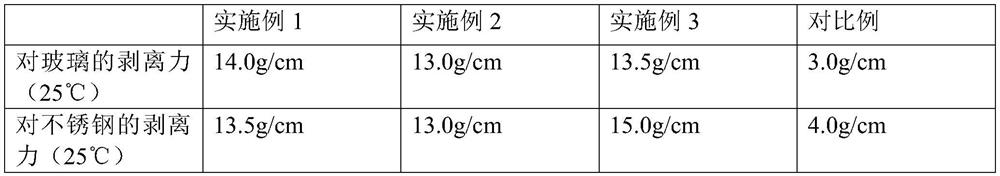

Examples

Embodiment 1

[0022] A kind of preparation method of polytetrafluoroethylene material with low coefficient of linear expansion and stickiness, in parts by weight, comprises the steps:

[0023] In an oxygen-free closed reactor, add 180 parts of water, 30 parts of n-butanol, 6 parts of glycidyl acrylate, 4 parts of 1,6-hexylbismaleimide, 4 parts of perfluorododecane Sodium phenyl sulfonate, 2 parts of polyacrylamide 6000, 1 part of azobisisoamyl imidazoline, 0.1 part of S,S'-bis(α,α'-dimethyl-α"-acetic acid) trithio Carbonate, start the agitator to disperse evenly to obtain a liquid phase, control the liquid phase to account for 15% of the reactor volume; then increase the stirring speed to 1400r / min to atomize the liquid phase in the reactor; Add tetrafluoroethylene, stop feeding tetrafluoroethylene when the pressure of the kettle is 3MPa; then keep the stirring speed at 1400r / min, heat the temperature inside the reactor to 100°C, and the reactor is connected with constant pressure nitrogen ...

Embodiment 2

[0026] A kind of preparation method of polytetrafluoroethylene material with low coefficient of linear expansion and stickiness, in parts by weight, comprises the steps:

[0027] In an oxygen-free closed reactor, add 150 parts of water, 40 parts of N,N-diethylformamide, 4 parts of hydroxyethyl methacrylate, 6 parts of p-phenylbismaleimide, 3 parts Add perfluorohexadecyltrimethylammonium bromide, 3 parts of polyvinylpyrrolidone, 0.8 parts of azobisisoheptyl imidazoline, 0.2 parts of α-dithiobenzyl p-benzylidene chloride Pyridinium salt, start the agitator to disperse evenly to obtain a liquid phase, control the liquid phase to account for 12% of the volume of the reactor; then increase the stirring speed to 1600r / min to atomize the liquid phase in the reactor; Add tetrafluoroethylene, stop feeding tetrafluoroethylene when the pressure of the kettle is 2.5MPa; then keep the stirring speed at 1600r / min, heat the temperature in the reactor to 90°C, and the reactor is connected wit...

Embodiment 3

[0030] A kind of preparation method of polytetrafluoroethylene material with low coefficient of linear expansion and stickiness, in parts by weight, comprises the steps:

[0031] In an oxygen-free closed reactor, add 130 parts of water, 50 parts of dimethyl sulfoxide, 3 parts of hydroxyisopropyl acrylate, and 8 parts of N,N'-(4,4'-methylenediphenyl) Bismaleimide, 2 parts of sodium perfluorooctyl carboxylate, 4 parts of polyethylene glycol 8000, 0.5 part of azodicyanovaleric acid, 0.3 part of dithiophenylacetic acid, and start the mixer to disperse evenly to obtain Liquid phase, control the liquid phase to account for 10% of the volume of the reactor; then the stirring speed is raised to 1800r / min to atomize the liquid phase in the reactor; Stop feeding tetrafluoroethylene at 2MPa; then keep the stirring speed at 1800r / min, heat the temperature in the reactor to 70°C, and keep the reactor pressure at 2MPa by connecting the reactor with constant pressure nitrogen during the whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com