Lubricating oil viscosity index improver as well as preparation method and application thereof

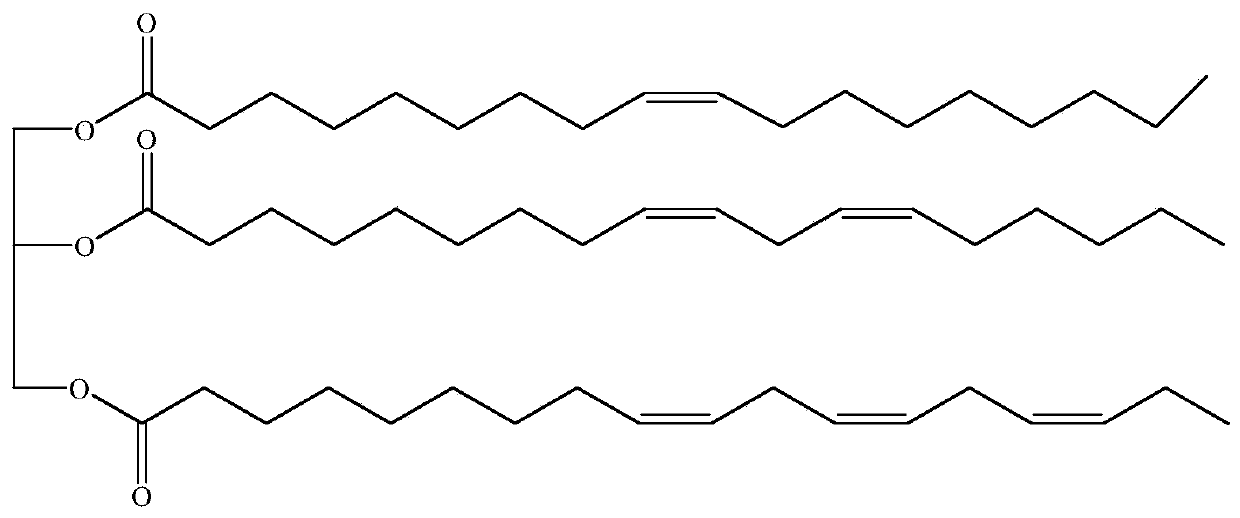

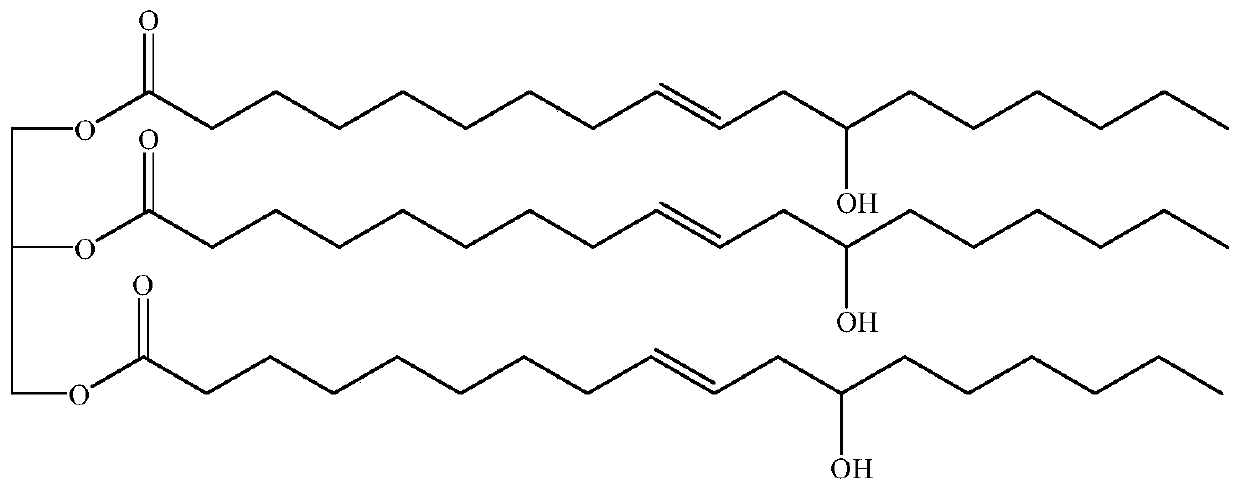

A viscosity index improvement and viscosity index technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of poor parallel reproducibility, wide relative molecular mass distribution, uncontrollable molecular mass, etc., and achieve excellent biodegradability, The relative molecular mass is controllable and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

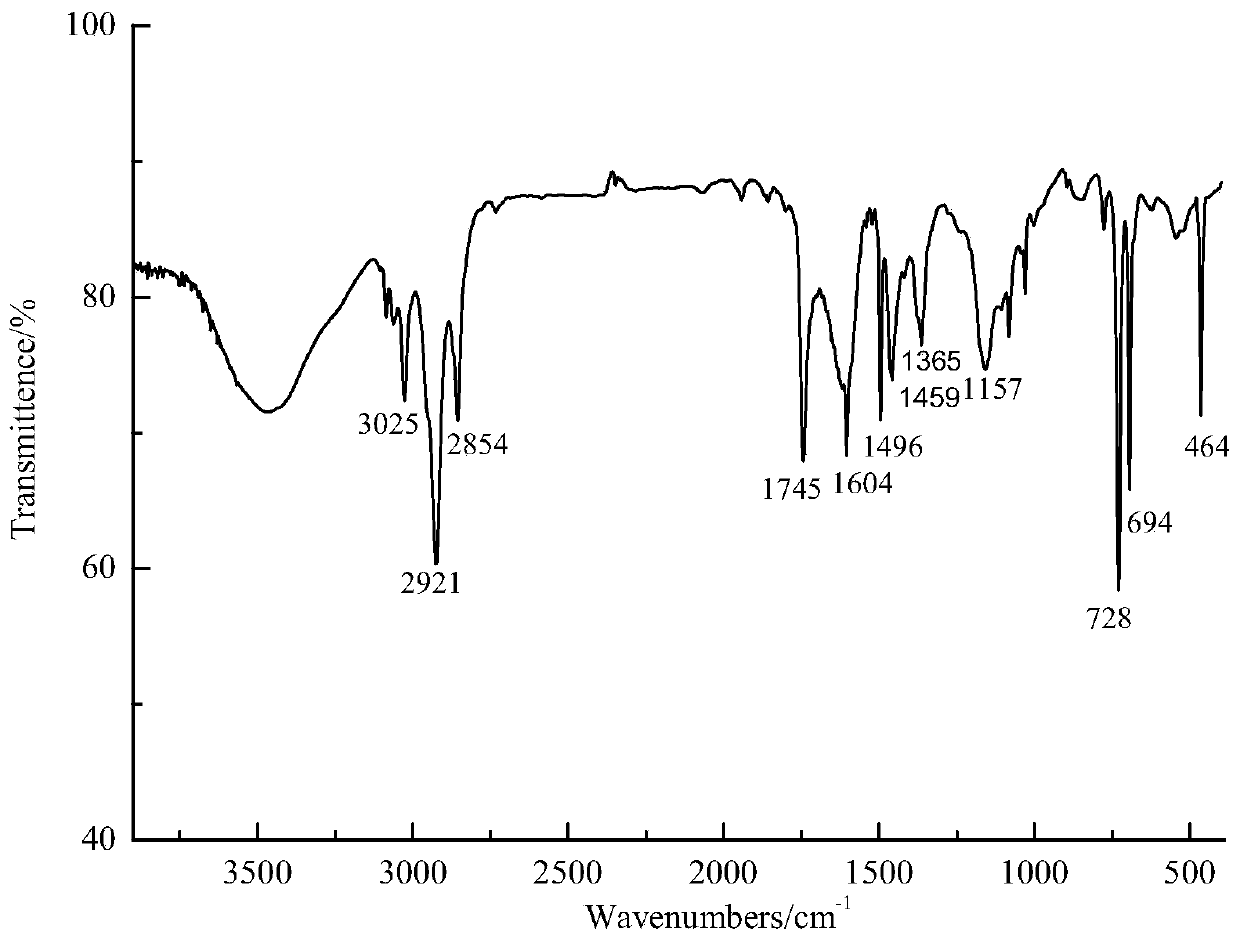

Image

Examples

Embodiment 1

[0053] A preparation method of viscosity index improver for lubricating oil, at room temperature, take 2.7g of styrene, 0.3g of soybean oil, 1.8×10 -5 mol catalyst, 5mL toluene in a dry three-necked round-bottom flask, anhydrous and oxygen-free operation, evacuated for 3 minutes, filled with nitrogen for 6 minutes, repeated twice, placed in a constant temperature oil bath, heated and stirred at 50°C for 30 minutes to obtain Homogeneous solution; inject the toluene solution of azobisisobutyronitrile in a nitrogen atmosphere, wherein the amount of azobisisobutyronitrile is 1% of the total monomer (styrene and soybean oil) quality, which is 0.03g, and it is dissolved In 3mL of toluene, react the reaction system in a constant temperature oil bath at 90°C for 8h; after the reaction, pour the solution in the flask into a beaker filled with 100mL of cold methanol at about 10°C, and filter it out after the solution is clarified. In the supernatant, the precipitate was vacuum-dried at ...

Embodiment 2

[0056] A preparation method of lubricating oil viscosity index improver, at room temperature, take 0.9g of styrene, 2.1g of castor oil, 1.8 × 10 -5 mol catalyst, 5mL toluene in a dry three-necked round-bottom flask, anhydrous and oxygen-free operation, evacuated for 3 minutes, filled with nitrogen for 6 minutes, repeated twice, placed in a constant temperature oil bath, heated and stirred at 50°C for 30 minutes to obtain Homogeneous solution; Then inject the toluene solution of azobisisobutyronitrile in a nitrogen atmosphere, wherein the amount of azobisisobutyronitrile is 0.1% of the total monomer (castor oil, styrene) quality, which is 0.0072g, which Dissolve in 5mL of toluene, and react the reaction system in a constant temperature oil bath at 90°C for 6 hours; after the reaction, pour the solution in the reaction tube into a beaker filled with 100mL of cold methanol at about 10°C, and filter it out after the solution is clarified In the supernatant, the precipitate was vac...

Embodiment 3

[0058] A preparation method of a viscosity index improver for lubricating oil, at room temperature, take 1.8g of styrene, 1.2g of soybean oil, 1.8×10 -5 mol catalyst, 5mL toluene in a dry three-necked round-bottom flask, anhydrous and oxygen-free operation, evacuated for 3 minutes, filled with nitrogen for 6 minutes, repeated twice, placed in a constant temperature oil bath, heated and stirred at 50°C for 30 minutes to obtain Homogeneous solution; inject the toluene solution of azobisisobutyronitrile in a nitrogen atmosphere, wherein the amount of azobisisobutyronitrile is 1% of the total monomer (styrene and soybean oil) quality, which is 0.03g, and it is dissolved In 3mL of toluene, react the reaction system in a constant temperature oil bath at 90°C for 8h; after the reaction, pour the solution in the flask into a beaker filled with 100mL of cold methanol at about 10°C, and filter it out after the solution is clarified. For the supernatant, the precipitate was vacuum-dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com