Waterborne polyurethanes, matte waterborne polyurethane and preparing methods

A water-based polyurethane, matte technology, applied in polyurea/polyurethane coatings, animal husbandry, chemical treatment of small raw hides/large raw hides/leather skins/furs, etc., can solve poor water resistance and abrasion resistance, poor wettability, and low gloss and other issues, to achieve good water resistance, improve wettability, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

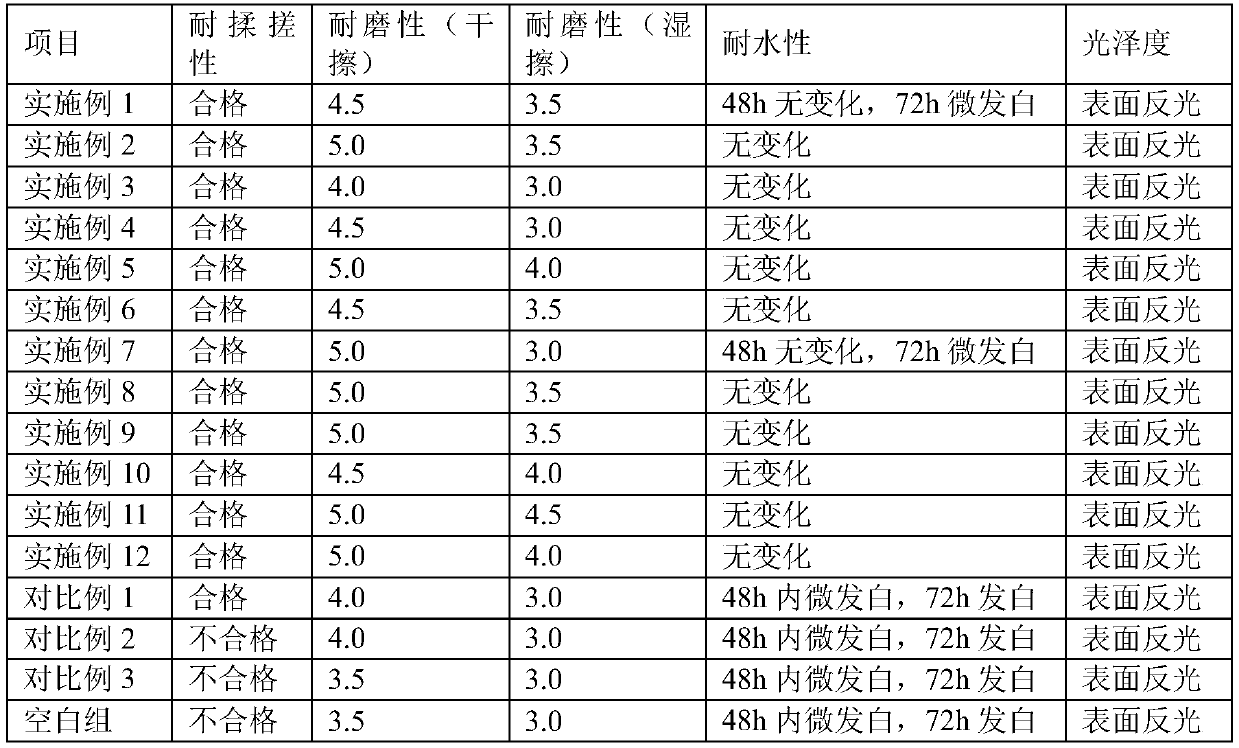

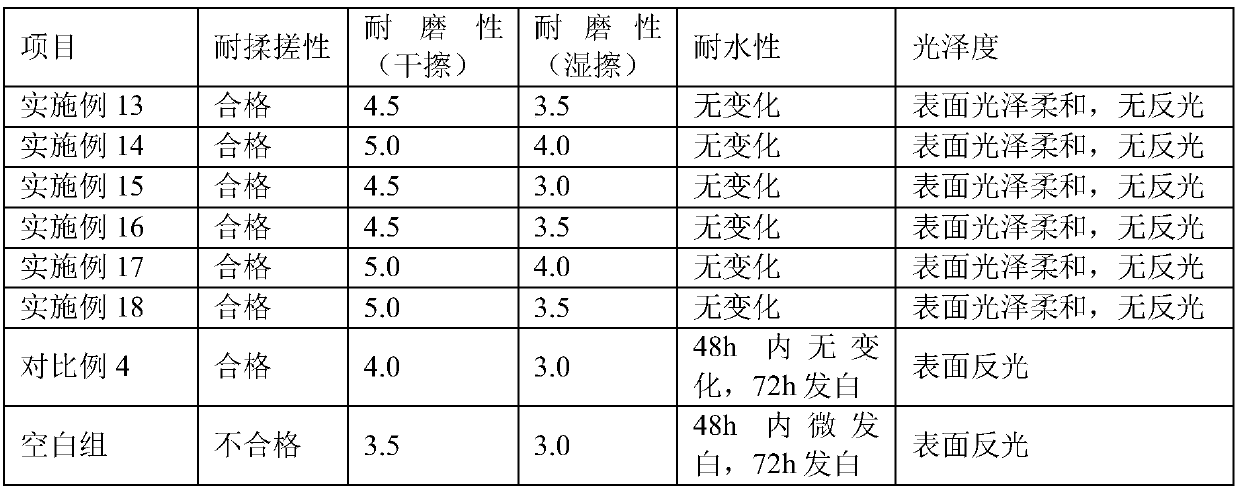

Examples

Embodiment 1

[0032] A kind of water-based polyurethane is prepared through the following steps:

[0033] (1) Heat 40g of diethylaminoethanol to 110°C in a vacuum environment for dehydration treatment for 1.5h (dehydration treatment is a conventional technical means in this field), then add 35g of isocyanic acid, and react for 1h at 75°C, Obtain mixed solution A;

[0034] (2) Add 15 g of thermoplastic polyurethane elastomer and 8 g of 1-4-butanediol to the mixed solution A, and react at 80° C. for 2 hours to obtain the mixed solution B of the polymerization reaction;

[0035] (3) Add a neutralizing agent to the mixed solution B to form a salt, here select ammonia water, adjust the pH to 7.5, add 5 g of deionized water, 1 g of hydrazine hydrate, and stir to disperse and emulsify at a stirring speed of 2000 r / min for 3 min, Then react at 20°C for 30 minutes to obtain a mixture C;

[0036] (4) Stir the mixed solution C at 20°C with a stirring speed of 2400r / min for 40min, and let it stand fo...

Embodiment 2

[0038] A kind of water-based polyurethane is prepared through the following steps:

[0039](1) Heat 40 g of diethylaminoethanol to 110° C. in a vacuum environment for dehydration treatment for 2 hours (dehydration treatment is a conventional technical means in this field), then add 35 g of isocyanic acid, and react for 2 hours at 80° C. to obtain Mixture A;

[0040] (2) Add 15 g of thermoplastic polyurethane elastomer and 8 g of 1-4-butanediol to mixed solution A, and react at 85° C. for 3 hours to obtain mixed solution B;

[0041] (3) Add a neutralizing agent to the mixed solution B to form a salt, select ammonia water here, adjust the pH to 8.5, add 5 g of deionized water, 1 g of hydrazine hydrate, and stir and emulsify at a stirring speed of 2000 r / min for 5 min, then in At 35°C, react for 40 minutes to obtain a mixture C;

[0042] (4) Stir the mixed solution C at 25° C. with a stirring speed of 4000 r / min for 50 minutes, and let it stand for 48 hours to obtain water-base...

Embodiment 3

[0044] A kind of water-based polyurethane is prepared through the following steps:

[0045] (1) Heat 40g of diethylaminoethanol to 110°C in a vacuum environment for dehydration treatment for 1.5h (dehydration treatment is a conventional technical means in this field), then add 35g of isocyanic acid, and react for 3h at 85°C, Obtain mixed solution A;

[0046] (2) Add 15 g of thermoplastic polyurethane elastomer and 8 g of 1-4-butanediol to mixed solution A, and react at 90°C for 4 hours to obtain mixed solution B;

[0047] (3) Add a neutralizing agent to the mixed solution B to form a salt, here select ammonia water, adjust the pH to 9, add 5g of deionized water, 1g of hydrazine hydrate, and stir and emulsify at a stirring speed of 2000r / min for 4min, then in At 50°C, react for 30 minutes to obtain a mixture C;

[0048] (4) Stir the mixed solution C at 25° C. with a stirring speed of 5000 r / min for 60 minutes, and let it stand for 48 hours to obtain water-based polyurethane. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com