High-strength modified polypropylene material and air-conditioner wind wheel made from high-strength modified polypropylene material

A polypropylene material and modified technology, applied in the field of PP/PTFE plastics, can solve the problems of reduced tensile strength and flexural strength, direct contact with humid air, and reduced structural strength of the wind wheel, and achieve tensile strength and flexural strength. Large, improve the waterproof and oil-proof performance, reduce the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

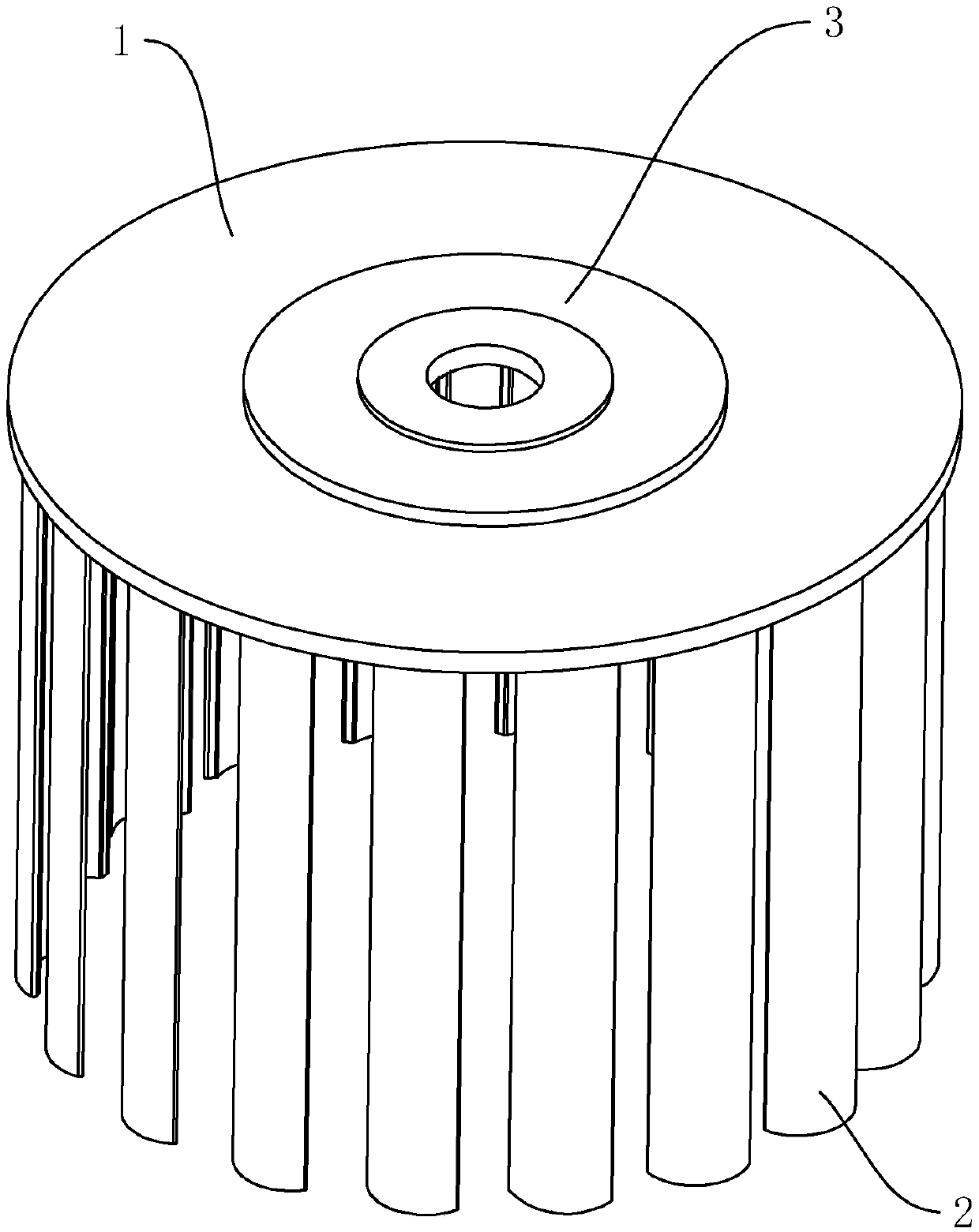

Image

Examples

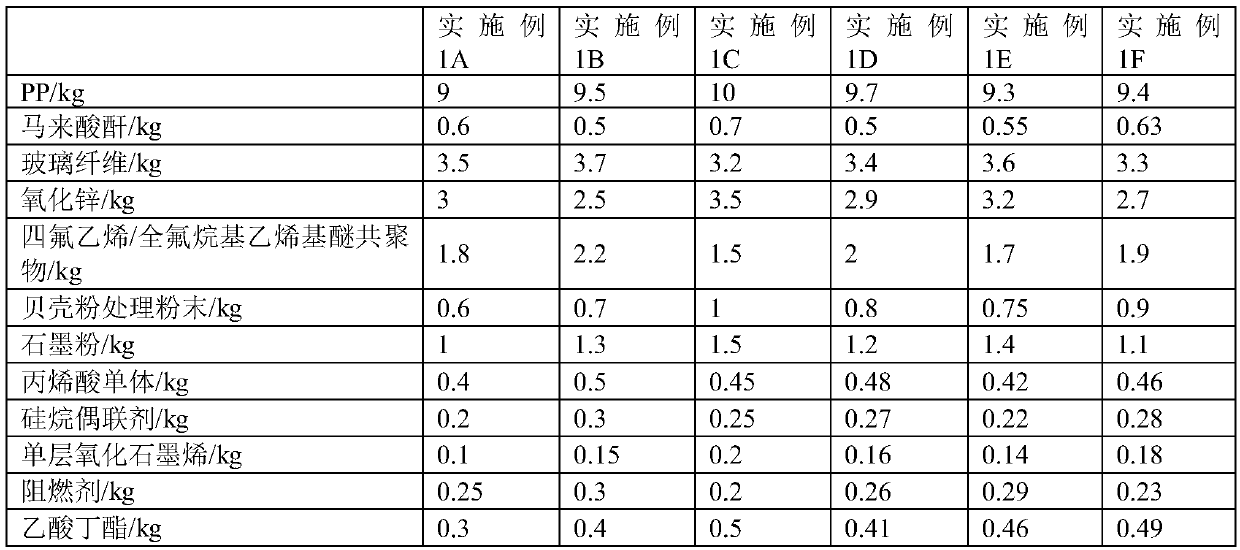

Embodiment 1

[0052] The modified polypropylene material contains the following parts by mass of raw materials mixed and melted:

[0053] PP 90-100 parts,

[0054] 5-7 parts of maleic anhydride,

[0055] 32-37 parts of glass fiber,

[0056] 25-35 parts of zinc oxide,

[0057] Tetrafluoroethylene / perfluoroalkyl vinyl ether copolymer 15-22 parts,

[0058] Shell powder processing powder 6-10 parts,

[0059] 10-15 parts of graphite powder,

[0060] Acrylic acid monomer 4-5 parts,

[0061] 2-3 parts of silane coupling agent,

[0062] 1-2 parts of monolayer graphene oxide,

[0063] 2-3 parts of flame retardant.

[0064] The length of the glass fiber is 2-3 mm, and the diameter is 10-15 μm. Here, the length of the glass fiber is 2.5 mm, and the diameter is 12 μm. Zinc oxide is a four-needle zinc oxide whisker. The diameter of the four-needle zinc oxide whisker is 460±5nm, and the length of a single needle is 6-8μm. Here, the length of the four-needle single-needle whisker is 7±0.2μm .

...

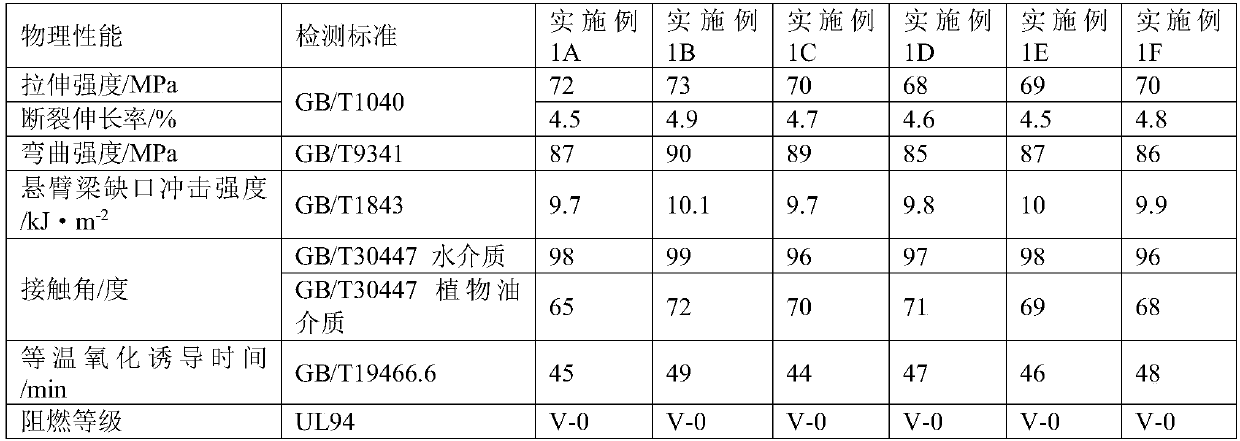

Embodiment 2

[0076] A modified polypropylene material, based on Example 1B, the difference is that the amount of butyl acetate is zero, and the modified polypropylene material is prepared based on the preparation method of the modified polypropylene material in Example 1 , to obtain the modified polypropylene material of Example 2.

Embodiment 3

[0078] A modified polypropylene material, based on Example 1B, the difference is that the amount of flame retardant is zero, and the modified polypropylene material is prepared based on the preparation method of the modified polypropylene material in Example 1 , to obtain the modified polypropylene material of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com