Thermal laminating film for printing matters

A thermal lamination, vinyl acetate technology, applied in the direction of film/sheet adhesive, adhesive type, adhesive, etc., can solve the problems of expensive materials, unsatisfactory printing layer adhesion, etc., to achieve excellent The effect of adhesion, prevention of color change, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

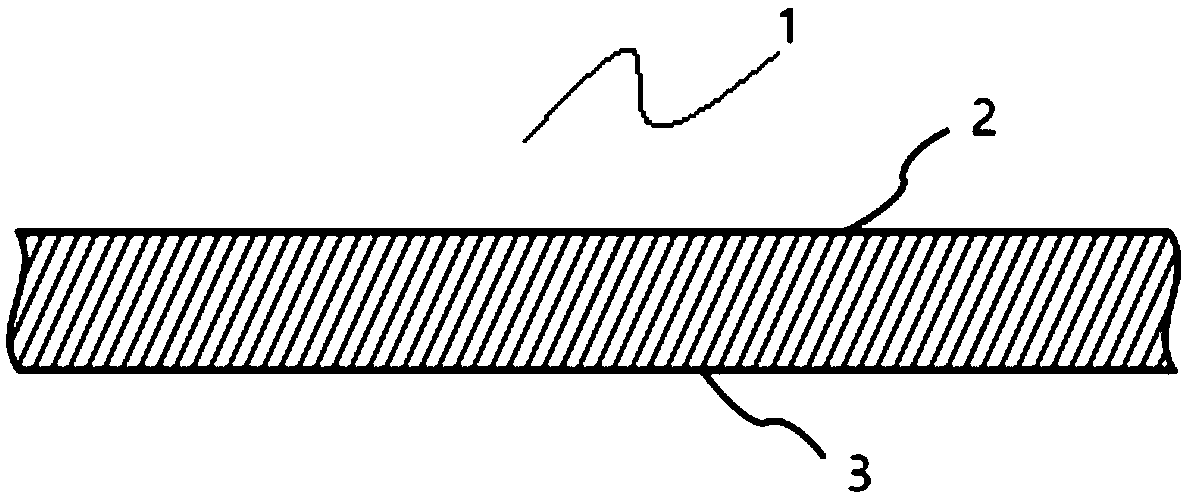

[0075] A polyester (PET) film was used as the base layer. Table 1 shows the thickness of the base layer. The base layer was subjected to corona discharge treatment to make the surface tension 50 dyne, and then a material for forming an adhesive layer was coated on the base layer with a bar coater. As the adhesive layer material, the emulsions shown in Table 1 were used. The base layer coated with the adhesive layer material was dried in a drying oven at 70° C. for 3 minutes, thereby preparing a thermal lamination film.

[0076] Ready to print digitally printed with water-based inks. The water-based ink is produced by Zhuhai Huacai Printing Consumables Co., Ltd. (product name: "Huacai"). The printed matter is printed in black, red, cyan, green, sky blue, pink and yellow.

[0077] The laminating equipment used the YIDU SAILS-320 model, to which thermal lamination films and prints were supplied at a speed of 4 m per minute, and thermal lamination was performed at 100°C. As a ...

Embodiment 13~21

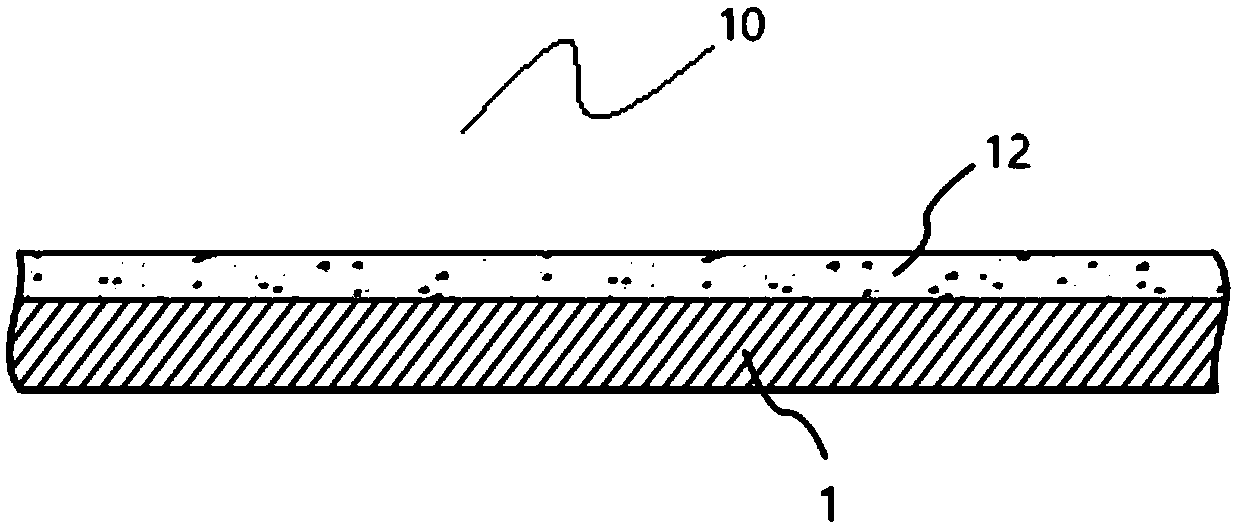

[0089] A laminated composite was prepared by the same method as in Example 1, except that a biaxially oriented polypropylene (BOPP) film with a thickness of 12 μm was used as the base layer and the experimental conditions were as shown in Table 2. Table 2 shows the evaluation of the adhesive force of the mounted composite.

[0090] Table 2

[0091]

[0092] As can be seen from Table 2, the thermal lamination films of Examples 13 to 21 have excellent adhesion to the printed matter.

Embodiment 22~23

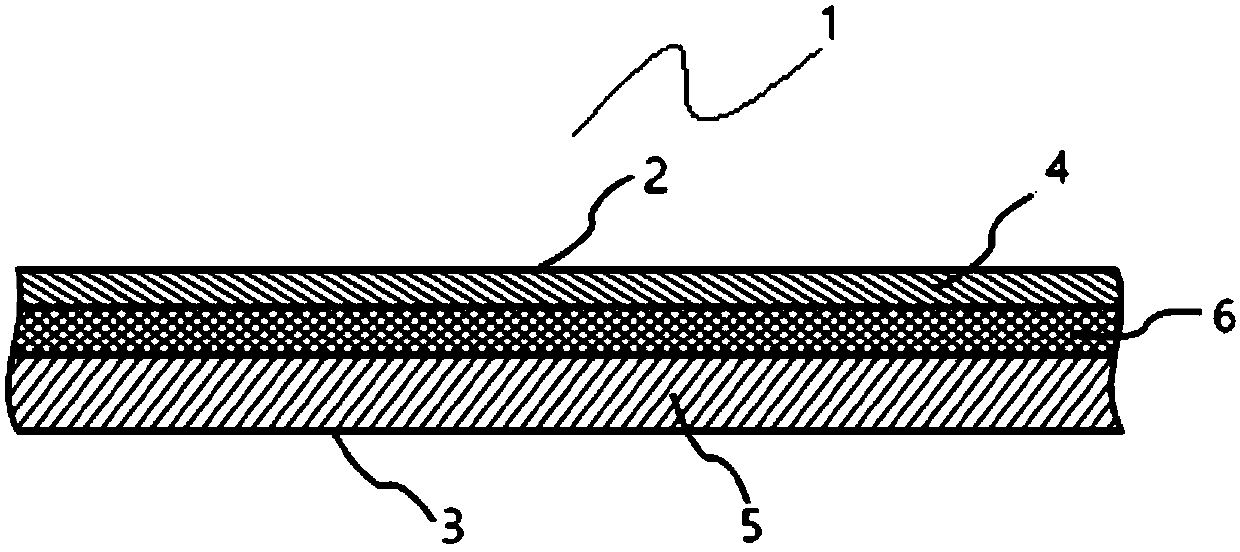

[0094] As the base layer, a PET film having a thickness of 52 μm was used. A polyurethane (PU)-based adhesive was coated with a thickness of 2 μm on the base layer and dried to form a primer layer. PU adhesive is an ordinary water-based PU adhesive generally used as a primer when dry laminating or preparing food packaging materials, and its viscosity is 70-100cps. The adhesive layer materials shown in Table 3 were coated on the primer layer with a bar coater and dried to prepare a thermal lamination film.

[0095] Other experimental conditions were the same as in Example 1, and the thermal lamination film and the printed matter were thermally laminated at 100° C. to form a lamination composite. The adhesive force of the mounted composite was evaluated, and the results are shown in Table 3.

[0096] table 3

[0097]

[0098] As can be seen from Table 3, the thermal lamination films of Examples 22 to 23 have excellent adhesion to the printed matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com