Ultra-low nitrogen oxide combustion method, matched combustion head and combustion device

A technology of nitrogen oxides and combustion method, applied in the field of combustion, can solve the problems of high cost, large energy consumption, vibration, etc., and achieve the effect of no operating cost, high combustion efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

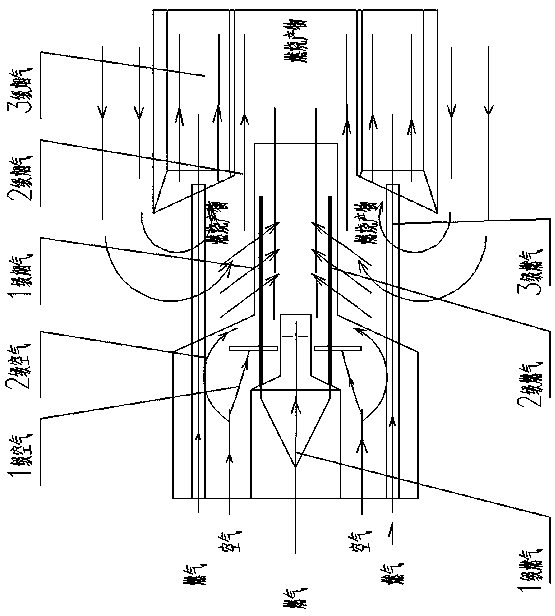

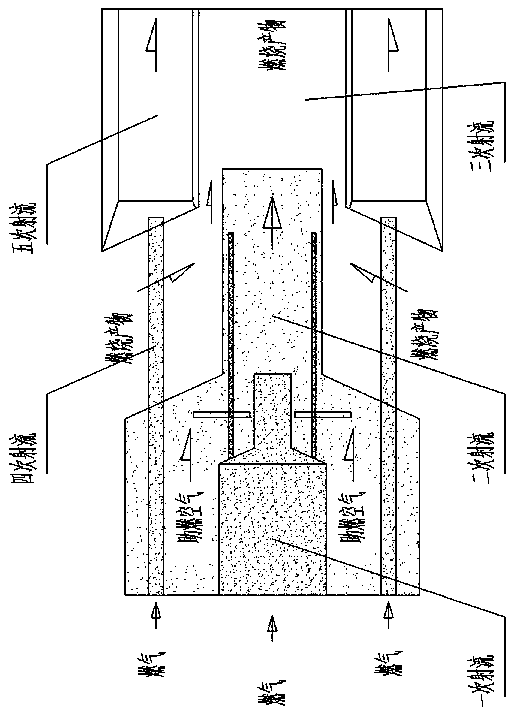

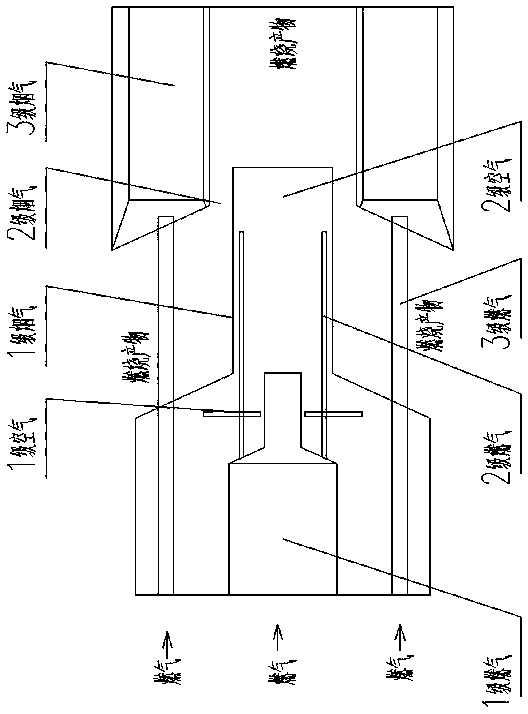

[0064] See attached Figure 1-9 , the present invention comprehensively utilizes the energy of gas and air itself, through multiple jet ejection of flue gas to form a sufficient mixture of gas and flue gas, air and flue gas fully mixed, and then effectively reduce the overall calorific value of gas and air content Oxygen content, and then through the comprehensive application of gas classification and air classification to achieve safe and reliable ultra-low nitrogen combustion effect. This technology does not need to introduce flue gas from the outside for back-burning, nor does it need to pre-mix gas and air at the fan, but directly injects gas into the furnace through the combustion head for combustion to achieve direct combustion technology with ultra-low NOx emissions. The direct-fired ultra-low NOx emission combustion device is a combustion devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com