Automatic measuring device and method for SO3 in flue gas

An automatic measurement and flue gas technology, which is applied in the field of pollutant testing, can solve the problems of easy measurement errors, weak degree of automation, and low measurement accuracy, and achieve the effects of convenient operation, reduced measurement impact, and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

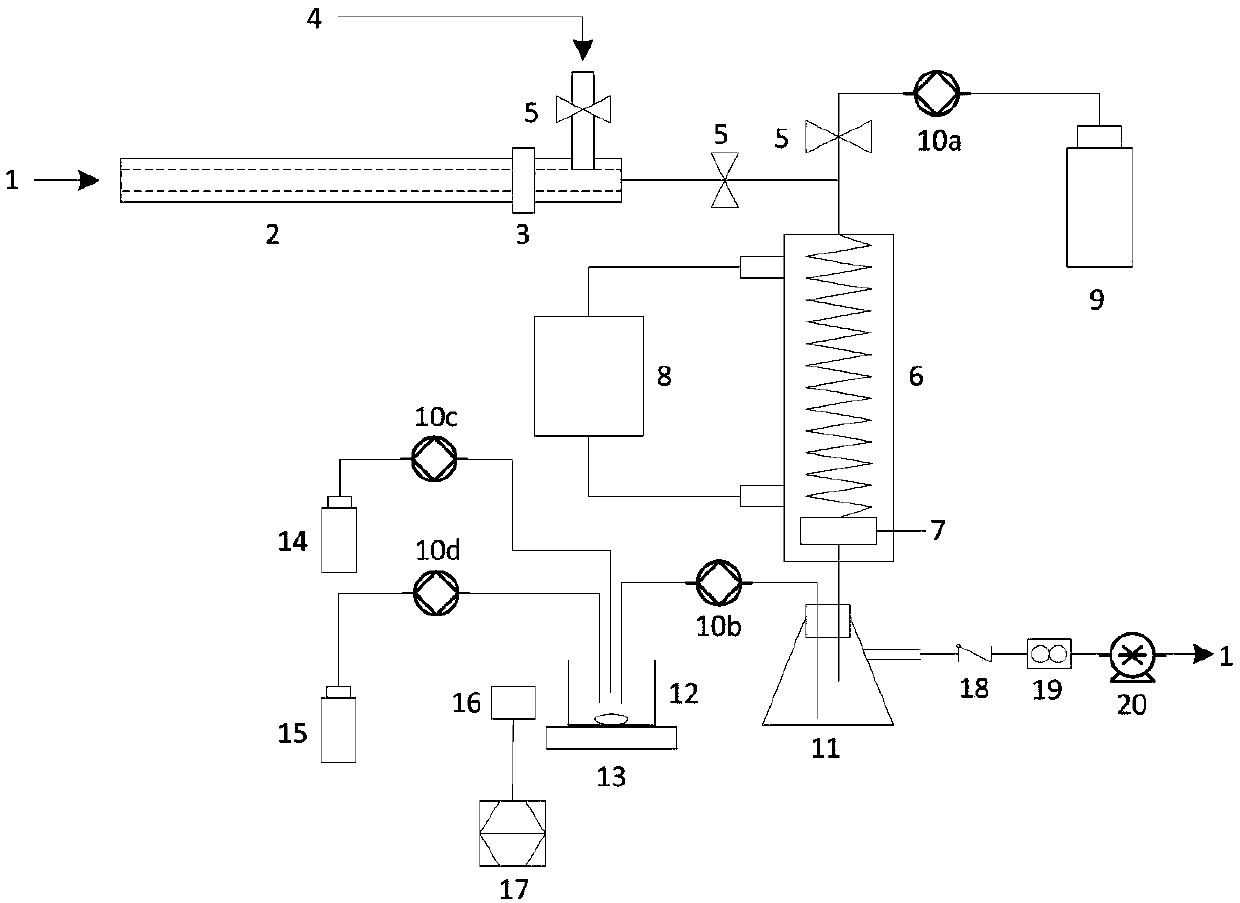

[0035] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, SO in a flue gas 3 The automatic measuring device includes a sampling system, a collection system, an analysis system and a control system. The flue gas 1 enters the sampling system, and the sampling system, the collection system, and the analysis system are connected in sequence through pipelines. The sampling system, the collection system, and the analysis system are all The signal is connected to the control system; wherein the sampling system includes a sampling gun 2, a filter 3 and a compressed air system 4, a filter 3 is installed at one end of the sampling gun 2, and a pipe is connected above the end of the sampling gun 2 Compressed air system 4; The sampling system also includes a check valve 18, a flow meter 19, and an air pump 20 connected in sequence through the pipeline, and the end of the check valve 18 away from the flow meter 19 is connected to the sample collection bottle 11 thr...

Embodiment 2

[0037] Embodiment 2: as figure 1 and figure 2 As shown, SO in a flue gas 3 The automatic measuring device includes a sampling system, a collection system, an analysis system and a control system. The flue gas 1 enters the sampling system, and the sampling system, the collection system, and the analysis system are connected in sequence through pipelines. The sampling system, the collection system, and the analysis system are all The signal is connected to the control system; wherein the sampling system includes a sampling gun 2, a filter 3 and a compressed air system 4, a filter 3 is installed at one end of the sampling gun 2, and a pipe is connected above the end of the sampling gun 2 Compressed air system 4; The sampling system also includes a check valve 18, a flow meter 19, and an air pump 20 connected in sequence through the pipeline, and the end of the check valve 18 away from the flow meter 19 is connected to the sample collection bottle 11 through a pipeline; The sys...

Embodiment 3

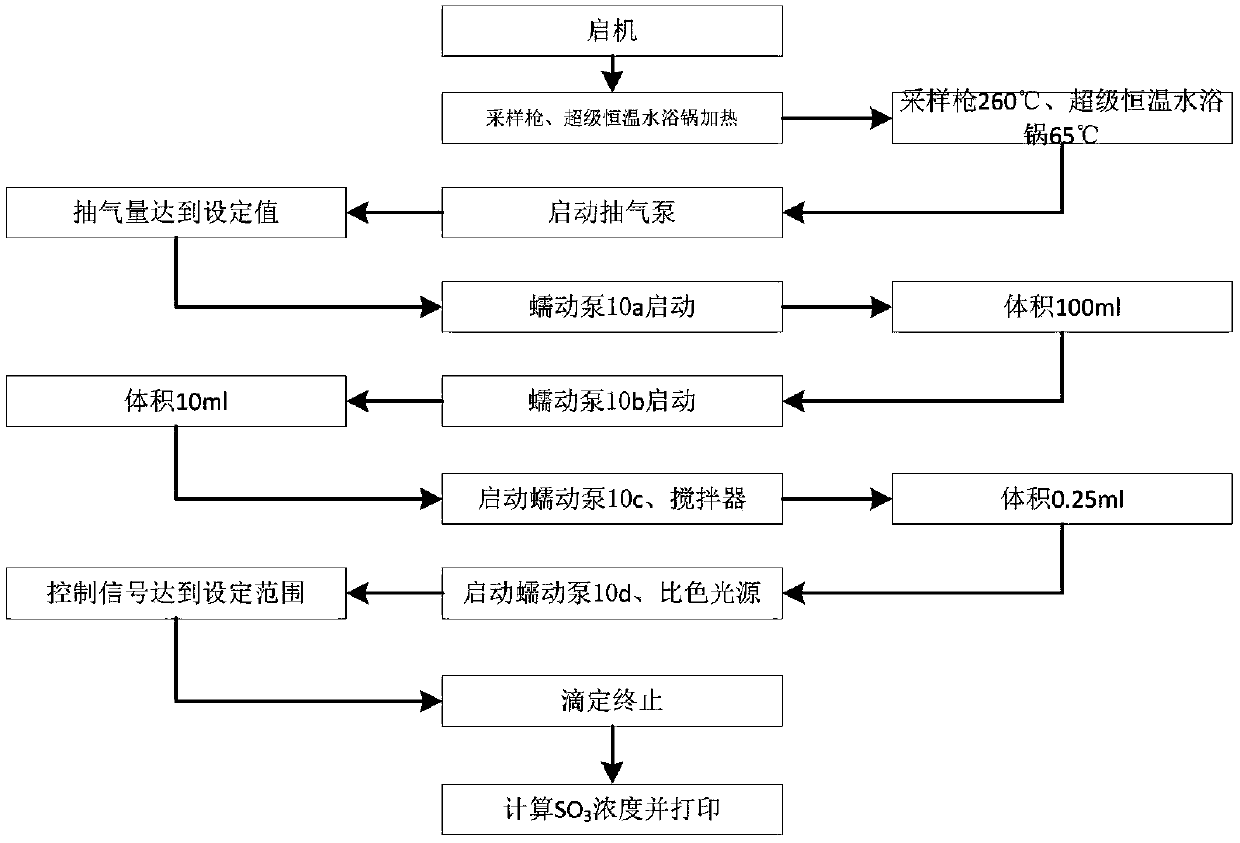

[0040] Embodiment 3: as figure 1 and figure 2 As shown, SO in a flue gas 3 Automatic measurement method, using the aforementioned SO in flue gas 3 Automatic measuring devices, including the following processes:

[0041] After the device is started, the sampling gun 2 and the super constant temperature water bath 8 start heating, and after reaching the design temperature, start the air pump 20;

[0042] The sampling gun 2 heats the extracted flue gas 1 to raise the temperature. After the flue gas passes through the filter 3 to remove dust, it enters the condenser 6. Under the action of the condenser 6 and the sintered glass filter 7, the SO in the flue gas 3 captured;

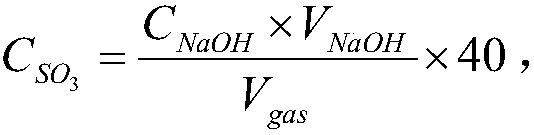

[0043] Start the peristaltic pump a10a on the pipeline connecting the eluent container 9 and the condenser 6, extract 100 ml of eluent from the eluent container 9 to flush the condenser 6 and the sintered glass filter 7, and then enter the sample collection bottle 11 to be trapped SO 3 The exhausted flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com