A design parameter determination method for a dual-motor drive high-frequency vibration ball mill

A high-frequency vibration and dual-machine drive technology, which is applied in computer-aided design, calculation, electrical digital data processing, etc., can solve the problems of high technical requirements of the exciter, high cost, and difficulty in accurately controlling the force and size of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

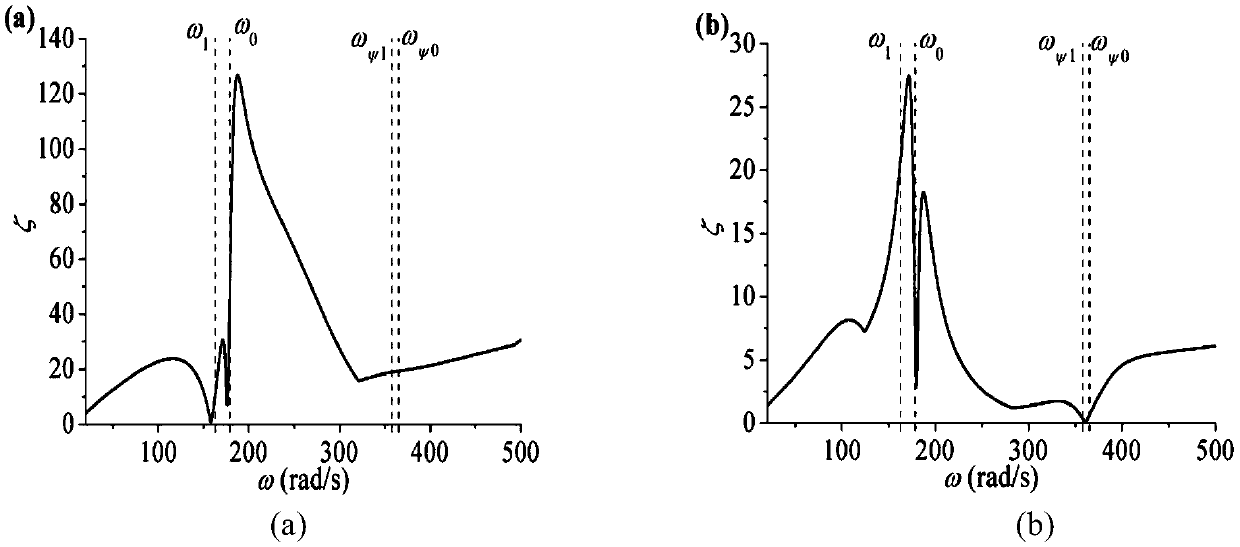

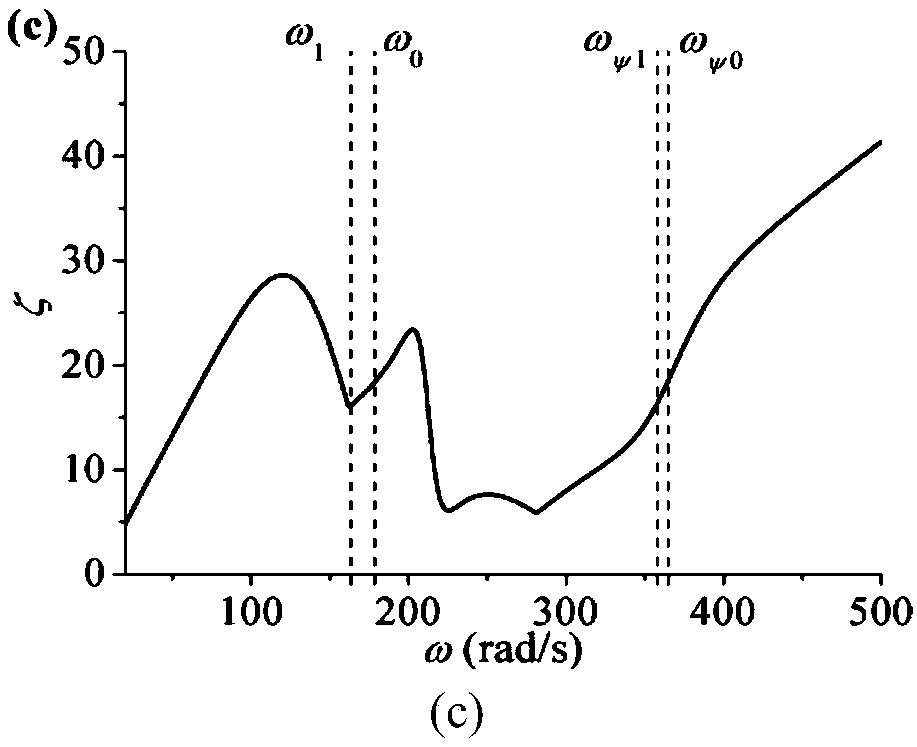

[0177] In order to further analyze the characteristics of the system, the dual-machine drive system is taken as the research object, and its numerical analysis is carried out.

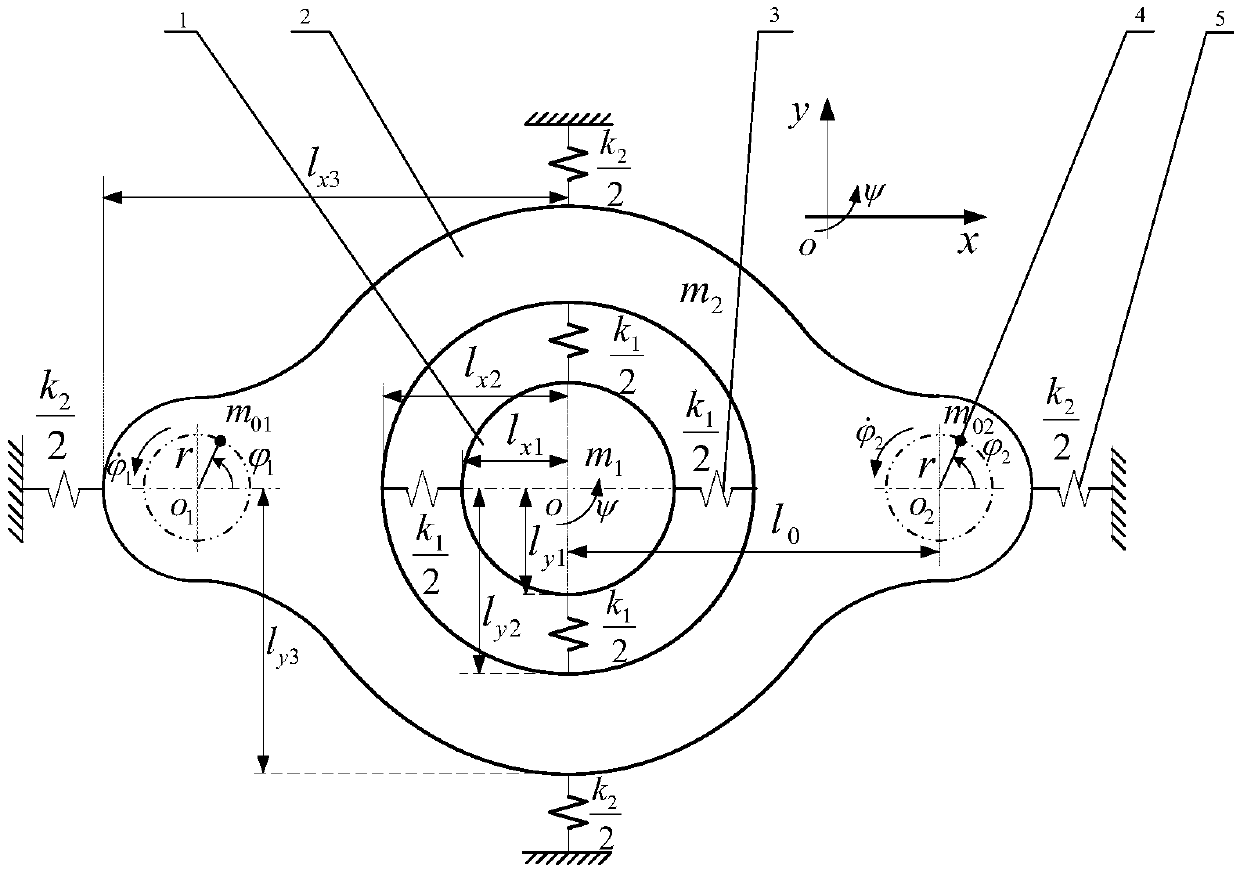

[0178] Parameters of the assumed vibration system: k 1 =8000kN / m,k ψ1 =6400kN / rad,k 2 =100kN / m,k ψ2 =88kN / rad,m 1 =300kG,m 2 =1500kG,J m1 =50kg·m 2 ,J m2 =1114.83kg·m 2 ,m 0 = 20kG, r = 0.15m, η = 1, ξ 1 =0.02,ξ 2 =0.07, ξ ψ1 =0.02, ξ ψ2 =0.07 and thus two natural frequencies ω 0 ≈178.5rad / s, ω 1 ≈163.3rad / s, ω ψ0 ≈365rad / s, ω 1 ≈357.8rad / s. Motor type: three-phase squirrel cage, 50Hz, 380V, 6-pole, 0.75kW, rated speed 980r / min. Motor parameters: rotor resistance R r =3.40Ω, stator resistance R s =3.35Ω, mutual inductance L m =164mH, rotor inductance L r =170mH, stator inductance L s =170mH,f d1 = f d2 = 0.05.

[0179] The coefficient ζ of the synchronization ability of the two rotors from the coupled dynamics is an index that can be used to describe the ability to adjust the ...

Embodiment 2

[0184]In order to further analyze and verify the numerical results, three sets of simulation results are given by the Runge-Kutta method. Vibration system parameters and motor parameters have been given in the previous section. In this section, in order to obtain the motion state of the system in different regions, generally by changing the spring stiffness k 1 and k ψ1 to adjust the value of the natural frequency.

[0185] Such as Figure 5 As shown, the spring stiffness k at this time 1 =5000kN / m,k ψ1 = 4000kN / rad to get 4 natural frequencies: ω 1 =129.1rad / s, ω 0 =141.1rad / s, ω ψ =282.8rad / s, ω ψ0 = 288.7 rad / s. Depend on Figure 5 (a) It can be seen that the synchronous speed of the motor is about 832.9r / min, that is, ω≈87.2rad / s, and there is z 0 = 0.62. At the same time, a π / 3 disturbance is given to motor 2 at 15s.

[0186] From Figure 5 (b) It can be seen that before interference, the phase difference is 2α=0°, corresponding to Figure 4 l of (b) 1 (ω=...

Embodiment 3

[0191] Below are example data parameters for one of the vibratory ball mills utilizing the present invention. The invention is not limited to this design parameter.

[0192] The parameters of the assumed vibration system: the spring stiffness k between the mass bodies 1 and 2 1 =3000kN / m, spring stiffness k between mass body 2 and foundation 2 =100kN / m, plastid 1 mass m 1 =300kG, plastid 2 mass m 2 =1500kG, mass of eccentric mass of exciter m 0 =20kG, the radius of gyration of the exciter r=0.15m, the motor speed 977.6r / min, at this time z ψ0 = 0.85. The system works in the region II. Due to the influence of the disturbance, the swing angles of the two rigid frames change very little, and the phases of the masses swinging in the ψ direction are the same, but their values are very small and can be ignored. Furthermore, the displacements of the plastids are all zero in the steady state. In this case, the vibration system can be considered to be in a steady state. (Moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com