Brown sugar ginger chrysanthemum granules and preparation method thereof

A technology of brown sugar ginger chrysanthemum and granules, applied in the field of food processing, can solve the problems of insignificant effect, single effect, low content of active ingredients, etc., and achieve the effects of improving immunity, promoting nutrient absorption, and promoting nutrient absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

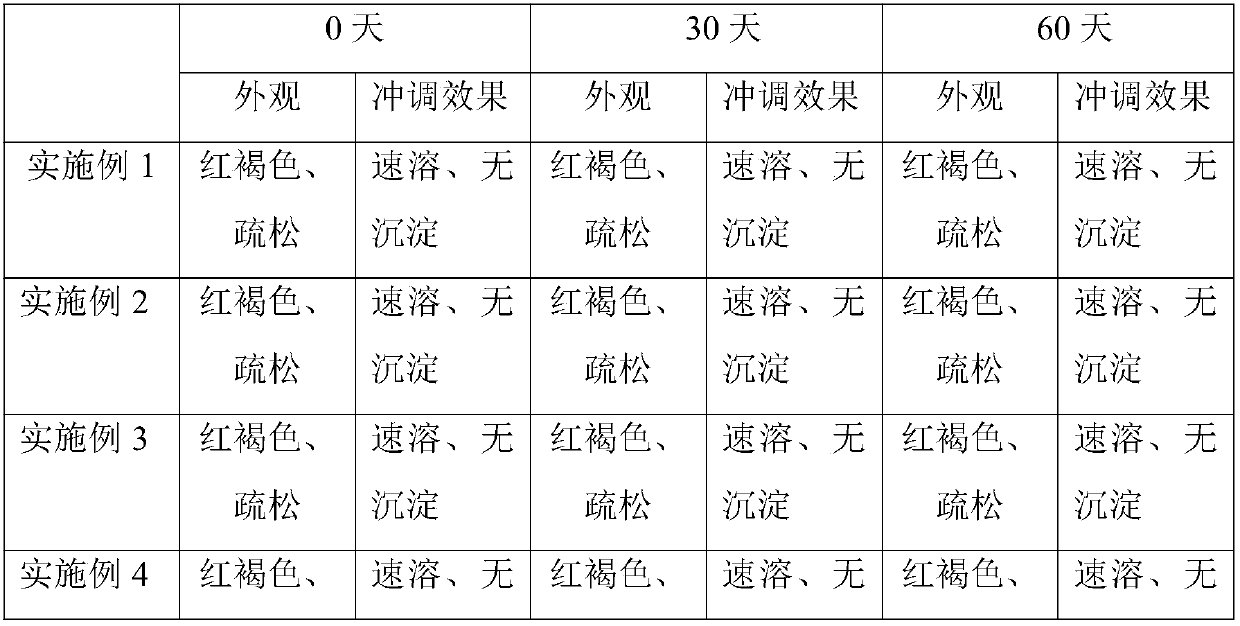

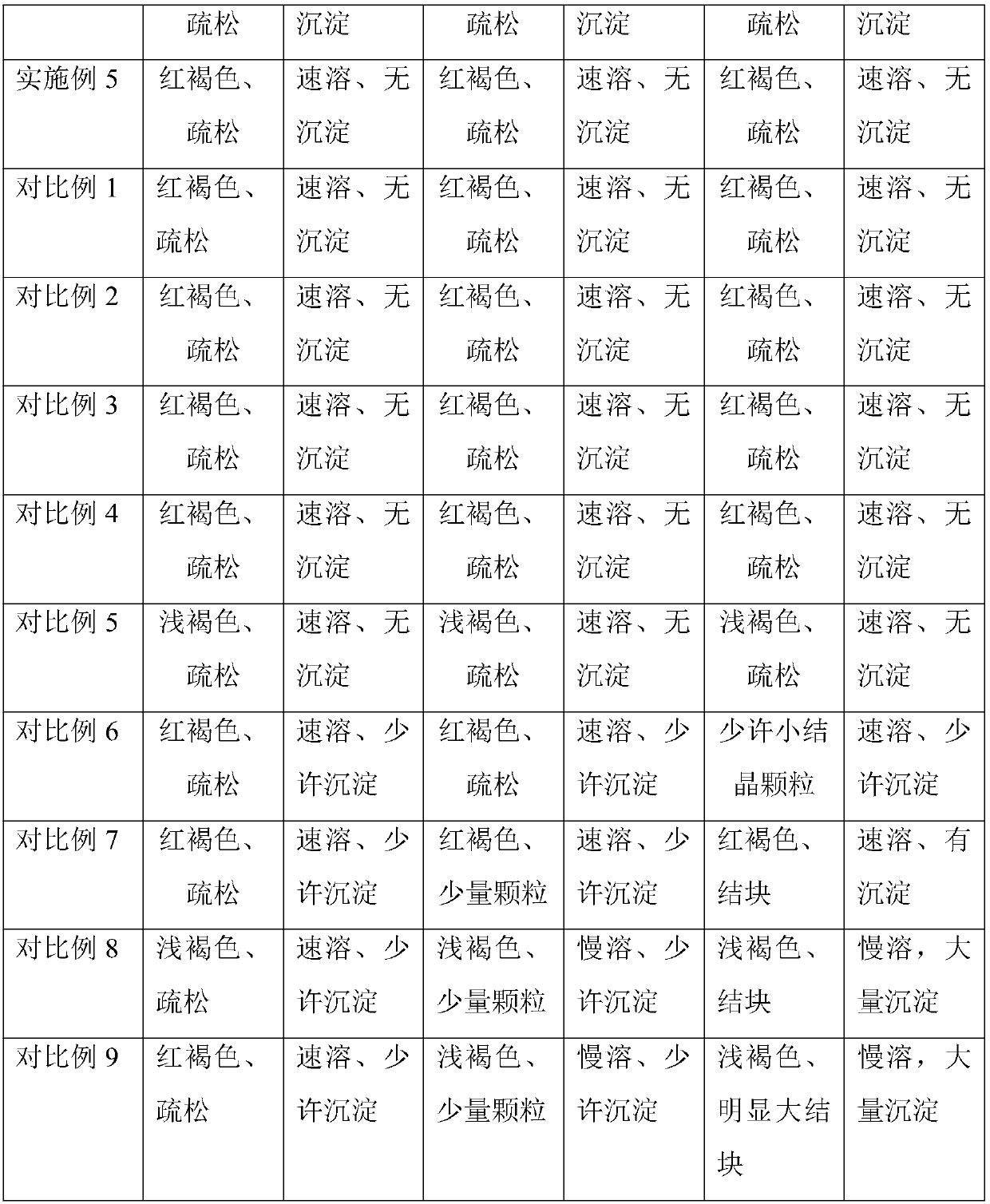

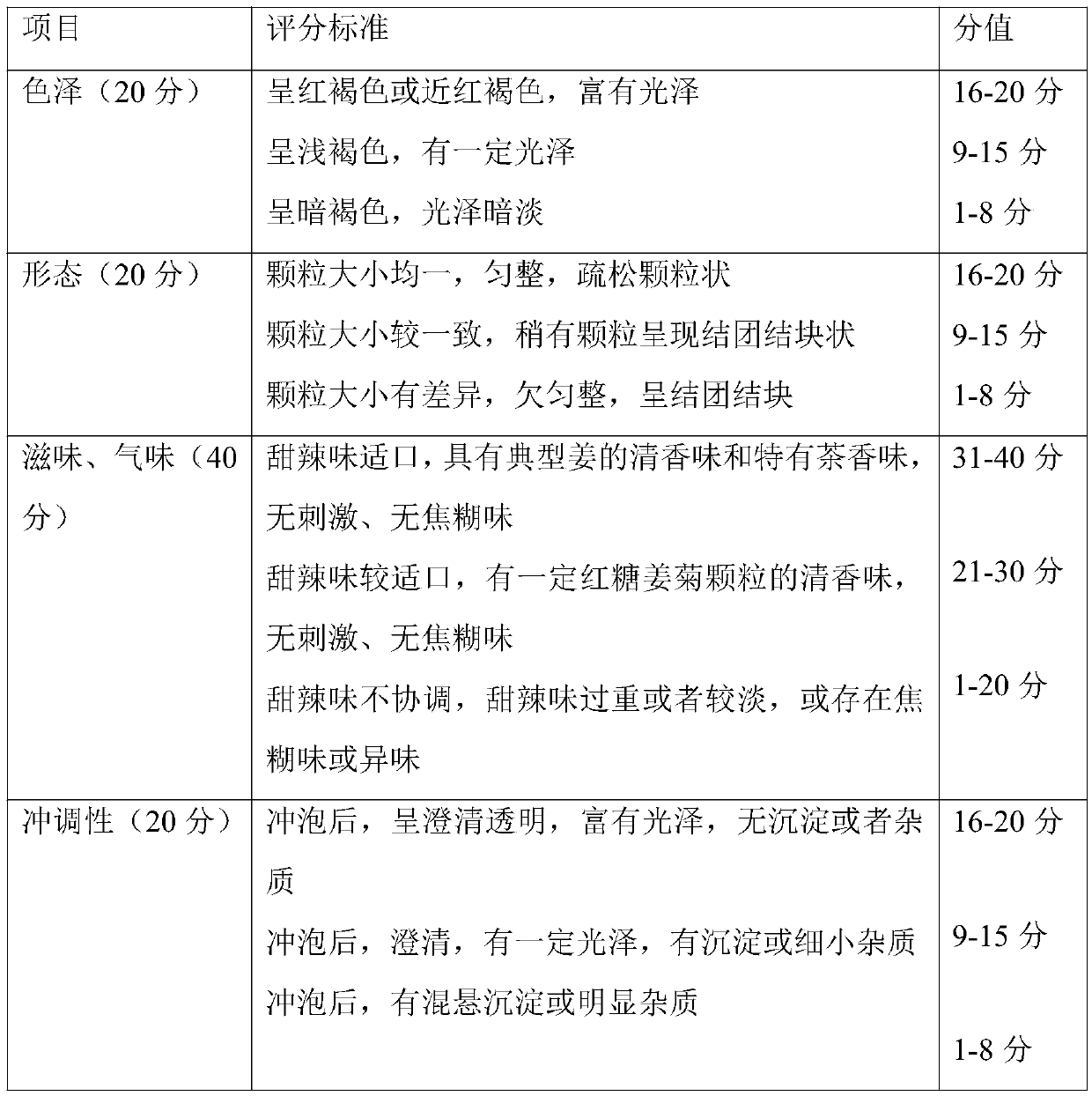

Examples

Embodiment 1

[0044] The preparation method of brown sugar ginger chrysanthemum granules specifically comprises the following preparation steps:

[0045] S1. Raw material processing: weigh brown sugar, chrysanthemum powder, and xylooligosaccharide powder, pulverize the brown sugar, and pass through an 80-mesh sieve; boil pure water, let it cool for later use;

[0046] S2. Mixing soft materials: 58 parts of brown sugar powder, 0.5 part of chrysanthemum powder, and 1 part of xylo-oligosaccharide powder sieved in step S1 are added to the tank mixer in sequence, and 1 part of ginger powder and 0.5 part of snake-toothed grape leaves are taken After the powder is mixed, pass through a 2-mesh manual sieve and add to the tank mixer, and stir for 6 minutes in a forward and reverse direction. While continuing to invert and stir, take the cooling water obtained in step S1 and spray 0.1 part of atomized water. After that, the color of the material is uniform and the agglomeration begins Agglomerates, s...

Embodiment 2

[0050] The preparation method of brown sugar ginger chrysanthemum granules specifically comprises the following preparation steps:

[0051] S1. Raw material processing: weigh brown sugar, chrysanthemum powder, and xylooligosaccharide powder, pulverize the brown sugar, and pass through a 90-mesh sieve; boil pure water, let it cool for later use;

[0052] S2. Mixing soft materials: Add 62 parts of brown sugar powder, 2 parts of chrysanthemum powder, and 2 parts of xylo-oligosaccharide powder sieved in step S1 to the tank mixer in sequence, and take 3 parts of ginger powder and 1 part of snake grape After the leaf powder is mixed, pass through a 6-mesh manual sieve and add to the tank mixer, and stir for 10 minutes in the forward and reverse directions. Agglomerates, stop spraying water, and get mixed material;

[0053] S3. Drying and sizing: dry the mixed material obtained in step S2 at 85°C, turn it over at the same time, bake at a constant temperature for 120 minutes after 30...

Embodiment 3

[0056] The preparation method of brown sugar ginger chrysanthemum granules specifically comprises the following preparation steps:

[0057] S1. Raw material processing: weigh brown sugar, chrysanthemum powder, and xylooligosaccharide powder, pulverize the brown sugar, and pass through a 90-mesh sieve; boil pure water, let it cool for later use;

[0058] S2. Mixing soft materials: add 66 parts of brown sugar powder, 4 parts of chrysanthemum powder, and 2.8 parts of xylo-oligosaccharide powder sieved in step S1 to the tank mixer in sequence, and take 5.6 parts of ginger powder and 1.6 parts of snake grape After the leaf powder is mixed, pass through a 10-mesh manual sieve and add to the trough mixer, and stir for 10 minutes in a forward and reverse direction. While continuing to reverse the stirring, take the cooling water obtained in step S1 and spray 1.2 parts of atomized water. Agglomerates, stop spraying water, and get mixed material;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com