Preparation method of anatomical type three-dimensional printing corrugated pipe elastic body tracheal stent and product

A 3D printing and tracheal stent technology, which is applied in stents, prostheses, medical science, etc., can solve the problems of epithelial crawling and granulation formation in the lumen, which are easy to attach and crawl, firm and difficult to fall out, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

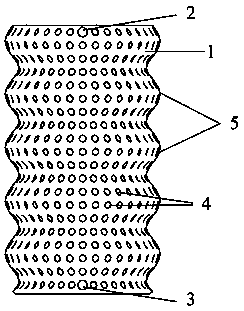

[0030] A method for preparing an anatomical 3D printed bellows-shaped elastomeric tracheal stent, using bioelastomer poly-1,8-octanediol-citric acid (POC) as the main structural material, and then preparing biodegradable stents by fused deposition modeling 3D printing Type tracheal stent material, follow the steps below:

[0031] Synthesis of POC: Put 1,8-octanediol and citric acid with a molar ratio of 1:1 in a three-necked flask, and heat it to 160°C under the protection of inert gas. The two monomers are completely melted and the reaction temperature is kept at 140°C. Continue stirring until the reaction Near the gel point, the prepolymer was dissolved in ethanol, and unreacted small molecules were precipitated with deionized water. After curing and cross-linking at 120°C, the POC raw material is obtained.

[0032] Cut the POC material into small pieces, stuff it into the printing cavity of the 3d plotter, preheat it at 110 degrees Celsius, and stack the layers with a heig...

Embodiment 2

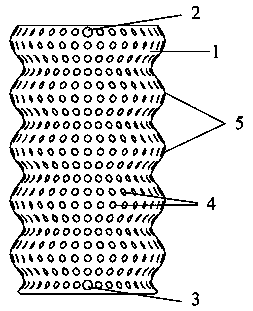

[0037] A preparation method of anatomical 3D printing bellows-shaped elastomeric tracheal stent, using bioelastomers poly-1,8-octanediol-citric acid (POC) and polycaprolactone (PCL) as the main structural materials, and then by melting To prepare degradable tracheal stent material by deposition modeling 3D printing method, follow the steps below:

[0038] Synthesis of POC: Put 1,8-octanediol and citric acid PCL with a molar ratio of 1:1 in a three-necked flask, add 30% by mass water PCL material, heat to 160°C under the protection of an inert gas, and completely melt to maintain the reaction temperature at 140°C, continue to stir until the reaction is close to the gel point, dissolve the prepolymer in ethanol, and use deionized water to precipitate unreacted small molecules. The POC-PCL raw material is obtained after post-curing and cross-linking at 120°C.

[0039] First, cut the POC-PCL raw material into small pieces and fill them into the cavity of the Haake rheometer preheat...

Embodiment 3

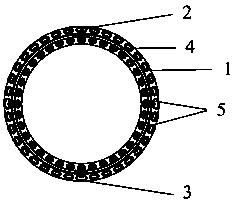

[0044] A method for preparing an anatomical 3D printed bellows-shaped elastomer tracheal stent, using bioelastomers poly-1,8-octanediol-citric acid (POC) and polycaprolactone (PCL) as the main structural materials, nano-sized Hydroxyapatite particles (Hap) are used as a filler, mixed with POC-PCL to form a POC-PCL / Hap masterbatch, and then a degradable tracheal stent material is prepared by fused deposition modeling 3D printing, as follows:

[0045] Put 1,8 octanediol and citric acid POC with a molar ratio of 1:1 in a three-necked flask, add PCL material with 30% water by mass, heat to 160°C under the protection of inert gas, and completely melt to keep the reaction temperature at 140°C. Continue to stir until the reaction is close to the gel point, dissolve the prepolymer in ethanol, and use deionized water to precipitate unreacted small molecules. The POC-PCL raw material is obtained after post-curing and cross-linking at 120°C. Add about 1% of nano-hydroxyapatite powder by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com