Wood fiber-coir composite sound absorption material and preparation method thereof

A technology of sound-absorbing material and wood fiber, applied in the direction of wood treatment, impregnating wood, wood impregnation, etc., can solve the problem that the sound-absorbing performance cannot meet the expected requirements, so as to improve the sound-absorbing effect, improve the porosity, and achieve the best sound-absorbing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiment of the present invention provides a method for preparing wood fiber-coconut fiber composite sound-absorbing material, comprising steps:

[0042] S101, taking wood fiber and coconut fiber, according to the mass ratio of wood fiber and coconut fiber is (1-9): 1 ratio, put wood fiber and coconut fiber into a mixer.

[0043] That is, 1 to 9 parts by mass of wood fiber corresponds to 1 part by mass of coconut fiber, and the quality of coconut fiber accounts for 10% to 50% of the total mass of coconut fiber and wood fiber.

[0044] S102, taking urea-formaldehyde resin glue, the amount of which is 5% to 12% of the sum of the mass of wood fiber and coconut fiber.

[0045] S103, adding a curing agent to the urea-formaldehyde resin glue, the amount of the curing agent added is 1% of the mass of the urea-formaldehyde resin glue.

[0046] S104, adding a foaming agent in an amount of 16% to 48% of the mass of the urea-formaldehyde resin glue to obtain a glue solution...

Embodiment 2

[0051] Embodiment 2 of the present invention is another embodiment of the preparation method of wood fiber-coir fiber composite sound-absorbing material, and this embodiment comprises steps:

[0052] S201, taking wood fiber and coconut fiber, according to the mass ratio of wood fiber and coconut fiber is 9:1, that is, the mass of coconut fiber accounts for 10%, put the wood fiber and coconut fiber into the mixer.

[0053] S202, get urea-formaldehyde resin glue, and the sizing amount is 5% of the sum of wood fiber and coconut fiber quality;

[0054] S203, adding a curing agent to the urea-formaldehyde resin glue, the amount of the curing agent added is 1% of the mass of the urea-formaldehyde resin glue.

[0055] Preferably, in this embodiment, the curing agent is ammonium chloride.

[0056] S204, then adding zinc oxide and azodicarbonamide as a foaming agent, adding the foaming agent, the amount of the foaming agent added is 16% to 48% of the quality of the urea-formaldehyde r...

Embodiment 3

[0061] Embodiment 3 of the present invention is another embodiment of the preparation method of wood fiber-coir fiber composite sound-absorbing material, and this embodiment comprises steps:

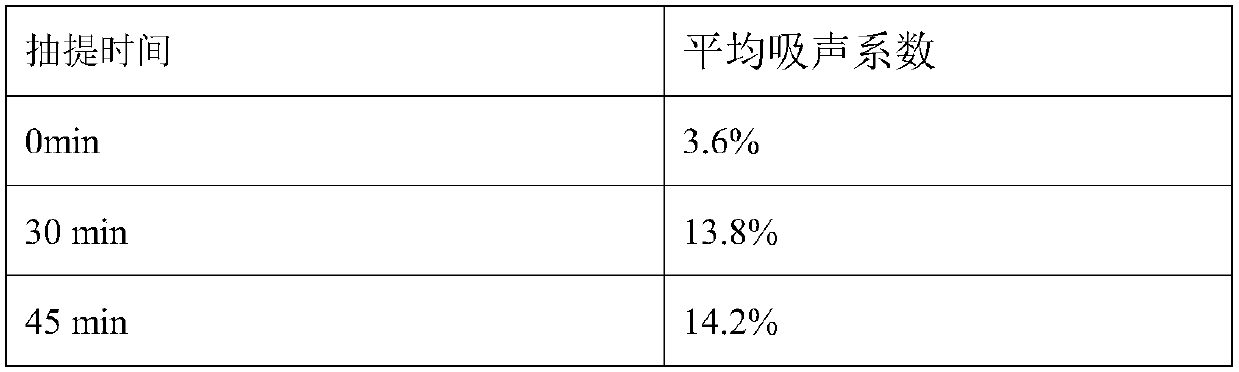

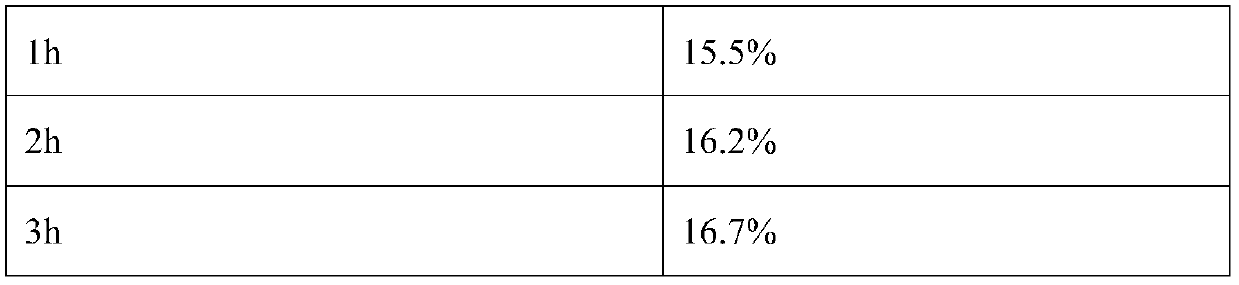

[0062] S301, the wood fiber is placed in a sodium hydroxide solution for alkali extraction treatment.

[0063] The concentration of sodium hydroxide is 0.5%-2%; the extraction temperature is 60°C-100°C; the extraction time is 30min-3h. Then put it into an oven for drying, the drying temperature is 120-130 degrees, and the drying time is 6-8 hours.

[0064] S302, putting the coconut fiber into an oven with a drying temperature of 100-110° C. to dry for 30-60 minutes. When the drying is completed and taken out, the fibers are relatively dispersed and there is no longer aggregation.

[0065] S303, taking wood fiber and coconut fiber, according to the ratio of the mass ratio of wood fiber and coconut fiber being 4:1, that is, the mass of coconut fiber accounts for 25%, put the wood fiber an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com