Method for producing ammonium sulfate by using industrial waste sulfuric acid

A waste sulfuric acid and ammonium sulfate technology, applied in chemical instruments and methods, ammonia compounds, inorganic chemistry, etc., can solve the problems of low treatment cost, high investment cost, cumbersome operation, etc., achieve low treatment cost, avoid excessive COD, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

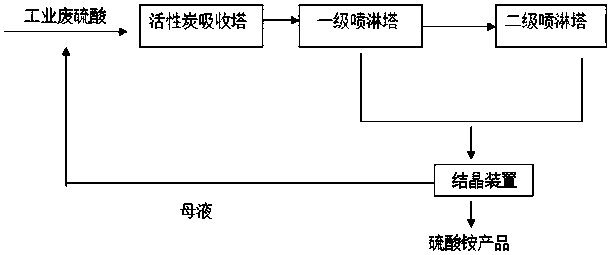

[0024] Process flow of the present invention such as figure 1 As shown, the specific steps are as follows:

[0025] Get 1313g of waste sulfuric acid with a mass fraction of 47.69%, add tap water, dilute to 1431g, then pass the diluted waste sulfuric acid through an activated carbon absorption tower, remove organic matter therein, after activated carbon treatment, the COD value in the waste sulfuric acid is 9mg / L;

[0026] Put the waste sulfuric acid after the above treatment into the two-stage spray tower. The steps are: the waste sulfuric acid is sprayed circularly in the first-stage spray tower, and at the same time, ammonia gas is introduced from the bottom of the first-stage spray tower to adjust the spray speed of the waste sulfuric acid. and ammonia enter the speed, keep the pH in the tower at 2.3, and the temperature at 25-30°C, stop spraying when white crystals are precipitated in the tower, and then start circulating spraying of waste sulfuric acid in the secondary sp...

Embodiment 2

[0030] Take 100g of waste sulfuric acid with a mass fraction of 47.69%, and pass it through an activated carbon absorption tower to remove organic impurities. After adsorption, the COD of waste sulfuric acid is 9.6mg / L.

[0031] Mix the treated waste sulfuric acid with 160.85g of the previous batch of mother liquor, and enter the two-stage spray tower. The steps are: first, the waste sulfuric acid is circulated and sprayed in the first-stage spray tower, and at the same time, ammonia is injected from the bottom of the first-stage spray tower. Gas, adjust the spraying speed of waste sulfuric acid and the entering speed of ammonia gas, keep the pH in the tower at 2.5, and the temperature at 25-30°C, stop spraying when white crystals are precipitated in the tower, and then put the waste sulfuric acid in the secondary spray tower Start circulating spraying in the middle, ammonia gas continues to enter the secondary spray tower to react, keep the pH in the tower at 2.5, and the temp...

Embodiment 3

[0035] Take 71.0 g of waste sulfuric acid with a mass fraction of 47.69%, and pass it through an activated carbon absorption tower to remove organic impurities. After adsorption, the COD of waste sulfuric acid is 8.9 mg / L.

[0036]Mix the treated waste sulfuric acid with 183.74g of the previous batch of mother liquor, and enter the two-stage spray tower. The steps are: first, the waste sulfuric acid is circulated and sprayed in the first-stage spray tower, and at the same time, ammonia is injected from the bottom of the first-stage spray tower. Gas, adjust the spraying speed of waste sulfuric acid and the speed of ammonia gas entry, keep the pH in the tower at 3.0, and the temperature at 25-30°C, stop spraying when white crystals are precipitated in the tower, and then put the waste sulfuric acid in the secondary spray tower Start circulating spraying in the middle, ammonia gas continues to enter the secondary spray tower to react, keep the pH in the tower at 3.0, and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com