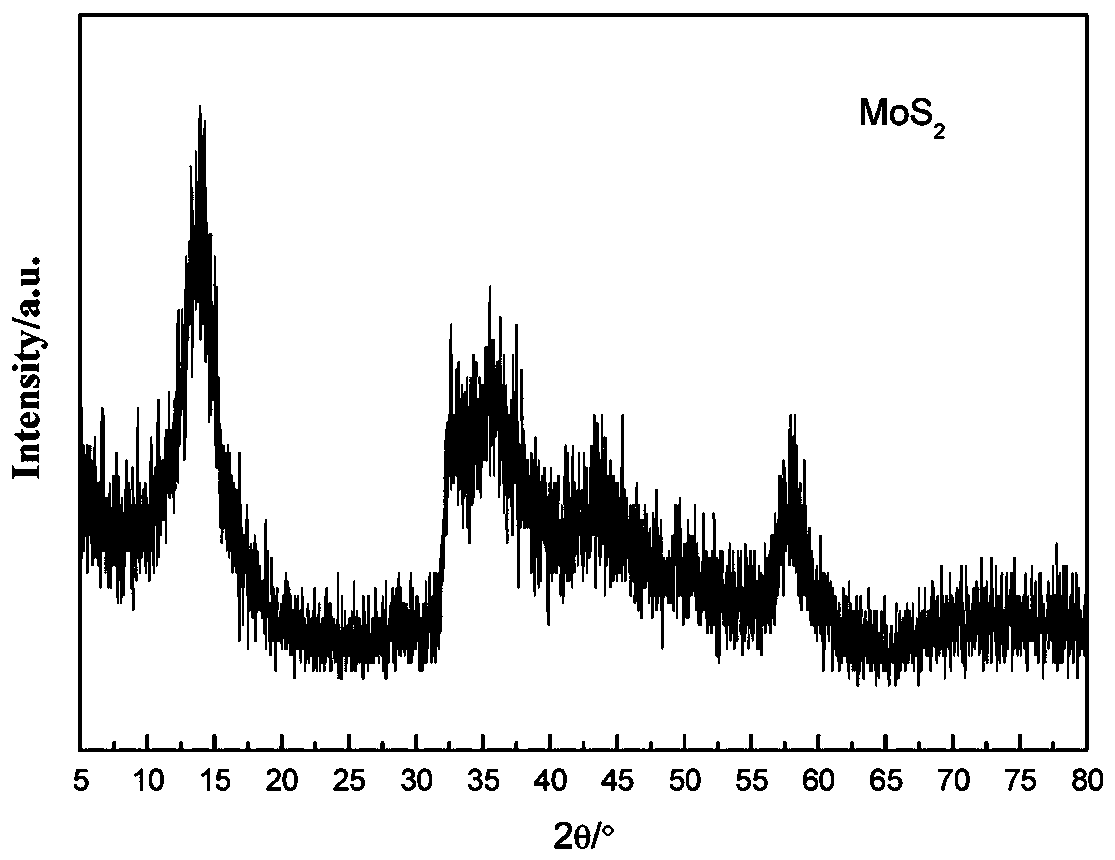

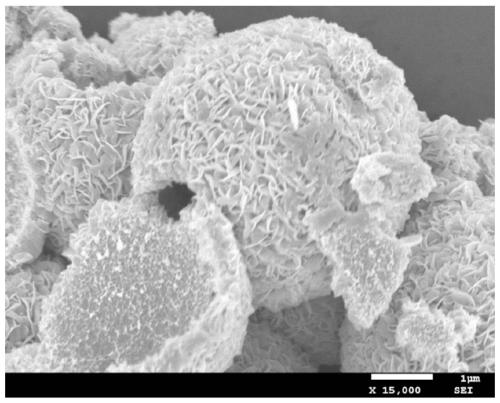

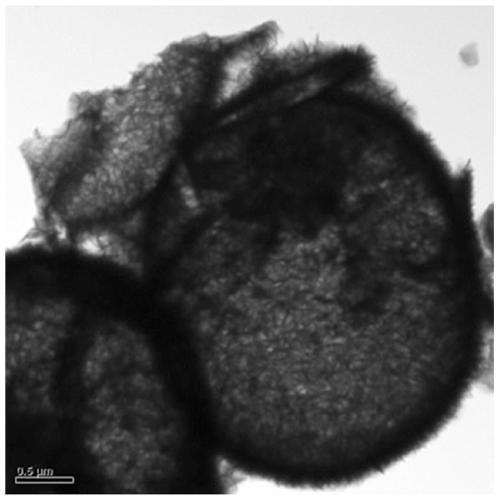

Preparation method and application of hollow MoS2 microspheres

A microsphere, hollow technology, applied in chemical instruments and methods, other chemical processes, molybdenum sulfide, etc., can solve the problems of less MoS2 material, ultra-thin nanosheet separation, difficulty in collection, limited application, etc., and achieve rich reactive sites. point, convenient for industrial application, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Add 4.054g of ferric chloride hexahydrate (FeCI 3 ·6H 2 O) and 1.2g of hexamethylenetetramine (HMT) were added into a beaker equipped with 30ml of ethanol / water mixed solvent with a volume ratio of 1:1, and stirred to completely dissolve it. Then add 1.0wt% copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 0), after stirring for 30min, the solution was transferred to a 50ml hydrothermal reaction kettle, after 180°C hydrothermal reaction for 24h, the sample was taken out after cooling, washed with absolute ethanol and deionized water, centrifuged, and finally put into a drying box for 80 Dry at ℃ for 10h to obtain Cu-α-Fe 2 o 3 as a template.

[0030] 2) Add 0.35g ammonium molybdate tetrahydrate ((NH 4 )6Mo 7 o 24 4H 2 O), 0.76g thiourea (CN 2 h 4 S) was dissolved in 20ml deionized water, and stirred with magnetic force for 30min to make it completely dissolved, then added 20mg of Cu-α-Fe obtained 2 o 3 , stir for 30 minutes to make it completely dispersed, t...

Embodiment 2

[0040] 1) 2.1g of ferric chloride hexahydrate (FeCl 3 ·6H 2 O) and 1.5g of hexamethylenetetramine (HMT) were added into a beaker equipped with 30ml of ethanol / water mixed solvent with a volume ratio of 1:1, and stirred to completely dissolve it. Then add 3.0wt% copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 0), after stirring for 30min, the solution was transferred to a 50ml hydrothermal reaction kettle, after 180°C hydrothermal reaction for 24h, the sample was taken out after cooling, washed with absolute ethanol and deionized water, centrifuged, and finally put into a drying box for 80 Dry at ℃ for 10h to obtain Cu-α-Fe 2 o 3 as a template.

[0041] 2) Add 0.5g ammonium molybdate tetrahydrate ((NH 4 )6Mo 7 o 24 4H 2 O), 0.8g thiourea (CN 2 h 4 S) was dissolved in 20ml deionized water, and stirred with magnetic force for 30min to make it completely dissolved, then added 20mg of Cu-α-Fe obtained 2 o 3 , stir for 30 minutes to make it completely dispersed, then add ...

Embodiment 3

[0051] 1) Add 3g of ferric nitrate and 1.5g of hexamethylenetetramine (HMT) into a beaker filled with 50ml of ethanol / water mixed solvent with a volume ratio of 1:2, and stir to dissolve them completely. Then add 2.0wt% copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 0), after stirring for 30min, the solution was transferred to a 50ml hydrothermal reaction kettle, after 160°C hydrothermal reaction for 20h, the sample was taken out after cooling, washed with absolute ethanol and deionized water, centrifuged, and finally put into a drying box for 80 Dry at ℃ for 10h to obtain Cu-α-Fe 2 o 3 as a template.

[0052] 2) Add 0.5g ammonium molybdate tetrahydrate ((NH 4 )6Mo 7 o 24 4H 2 O), 0.8g thiourea (CN 2 h 4 S) was dissolved in 20ml deionized water, and stirred with magnetic force for 30min to make it completely dissolved, then added 20mg of Cu-α-Fe obtained 2 o 3 , stir for 30 minutes to make it completely dispersed, then add it to a 50mL hydrothermal reaction kettle, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com