Method for manufacturing integrated lightweight structured wallboard by imitating form and structure of organisms

A wallboard and lightweight technology, applied in building construction, manufacturing tools, ceramic molding machines, etc., can solve problems such as difficulty in increasing production capacity, low production efficiency, and falling off of calcium silicate boards, so as to reduce the use of materials and improve production Efficiency, the effect of not degrading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

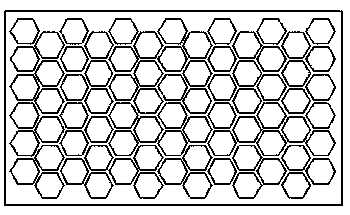

[0025] see figure 1 , the present invention provides a technical solution: a method for an integrally formed lightweight structural wallboard invented and manufactured by imitating the shape and structure of a creature, the specific steps are as follows:

[0026] S1, select materials according to the following parts by weight, 28 parts of cement, 10 parts of quartz sand, 10 parts of high molecular polymer, 10 parts of polymer fiber, 8 parts of light calcium carbonate, 30 parts of slag powder and crushed construction waste, water reducing 4 parts of agent, appropriate amount of quick-drying agent;

[0027] S2. Stir and mix cement, quartz sand, high molecular polymer, polymer fiber, light calcium carbonate, slag powder and crushed construction waste in a mechanical mixer to obtain a powder mixture, mix 5 parts of water reducing agent with quick-drying After an appropriate amount of the agent is uniformly dispersed in water, add it to the above-mentioned powder mixture, continue...

Embodiment 2

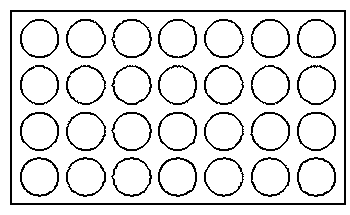

[0031] see figure 2 , the present invention provides a technical solution: a method for an integrally formed lightweight structural wallboard invented and manufactured by imitating the shape and structure of a creature, the specific steps are as follows:

[0032] S1, select materials according to the following parts by weight, 28 parts of cement, 10 parts of quartz sand, 10 parts of high molecular polymer, 10 parts of polymer fiber, 8 parts of light calcium carbonate, 30 parts of slag powder and crushed construction waste, water reducing 4 parts of agent, appropriate amount of quick-drying agent;

[0033] S2. Stir and mix cement, quartz sand, high molecular polymer, polymer fiber, light calcium carbonate, slag powder and crushed construction waste in a mechanical mixer to obtain a powder mixture, mix 5 parts of water reducing agent with quick-drying After an appropriate amount of the agent is uniformly dispersed in water, add it to the above-mentioned powder mixture, continu...

Embodiment 3

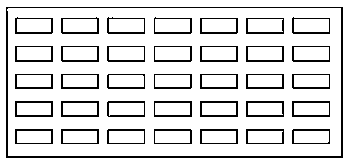

[0037] see image 3 , the present invention provides a technical solution: a method for an integrally formed lightweight structural wallboard invented and manufactured by imitating the shape and structure of a creature, the specific steps are as follows:

[0038] S1, select materials according to the following parts by weight, 28 parts of cement, 10 parts of quartz sand, 10 parts of high molecular polymer, 10 parts of polymer fiber, 8 parts of light calcium carbonate, 30 parts of slag powder and crushed construction waste, water reducing 4 parts of agent, appropriate amount of quick-drying agent;

[0039] S2. Stir and mix cement, quartz sand, high molecular polymer, polymer fiber, light calcium carbonate, slag powder and crushed construction waste in a mechanical mixer to obtain a powder mixture, mix 5 parts of water reducing agent with quick-drying After an appropriate amount of the agent is uniformly dispersed in water, add it to the above-mentioned powder mixture, continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com