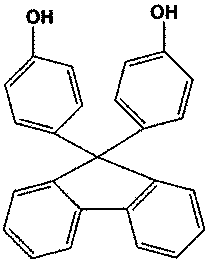

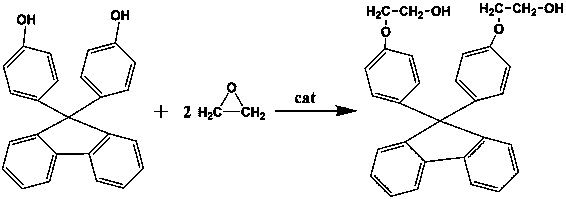

Preparing method of dihydroxyethyl bisphenol fluorene ether

A technology of bishydroxyethyl bisphenol fluorene ether and bisphenol fluorene, which is applied in the field of fine chemical synthesis, can solve the problems of high toxicity of solvents, and achieve the effects of increased reaction yield, less by-products, and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add 350g of bisphenol fluorene, 0.219g of triisopropylphosphine catalyst (the mass of the catalyst is 0.5‰ of the sum of the mass of bisphenol fluorene and ethylene oxide, the same below) and 140g Cyclohexane (40% of bisphenol fluorene mass), start stirring, vacuumize with vacuum pump, use N 2 Replace the air in the reactor. After three replacements, when the vacuum degree is ≥-0.095MPa, turn off the vacuum and start

[0038] Raise the temperature to dissolve the bisphenol fluorene and the catalyst in the solvent. When the temperature rises to 100°C, a small amount of ethylene oxide begins to pass through, and when the temperature rises to the reaction temperature of 120°C, the ethylene oxide begins to pass through stably, and continues to pass through the epoxy 88g of ethane, the reaction temperature is controlled at 120~125°C, the pressure of the reactor is controlled below 0.4MPa, after adding ethylene oxide, heat preservation and aging until the pressure in the reac...

Embodiment 2

[0041] Add 350g of bisphenol fluorene, 0.438g of triisopropylphosphine catalyst (1‰ catalyst) and 140g of cyclohexane (40% of the mass of bisphenol fluorene) in sequence in a stirring 2.5L reactor, and start stirring. Evacuate with a vacuum pump, using N 2Replace the air in the reactor. After three replacements, turn off the vacuum and start to heat up when the vacuum degree is ≥-0.095MPa, so that the bisphenol fluorene and the catalyst are dissolved in the solvent. When the temperature rises to 100°C, start to pass a small amount of ethylene oxide Alkanes, when the temperature rises to the reaction temperature of 120°C, start to pass ethylene oxide stably, continue to feed 88g of ethylene oxide, control the reaction temperature at 120~125°C, control the pressure of the reactor below 0.4MPa, and finish adding epoxy After heating with ethane, heat preservation and aging until the pressure in the reactor no longer drops. Then the temperature drops to about 105°C and starts nega...

Embodiment 3

[0044] Add 350g of bisphenol fluorene, 1.341g of triisopropylphosphine catalyst (3‰ catalyst) and 140g of cyclohexane (40% of the mass of bisphenol fluorene) in sequence in a stirring 2.5L reactor, and start stirring. Evacuate with a vacuum pump, using N 2 Replace the air in the reactor. After three replacements, turn off the vacuum and start to heat up when the vacuum degree is ≥-0.095MPa, so that the bisphenol fluorene and the catalyst are dissolved in the solvent. When the temperature rises to 100°C, start to pass a small amount of ethylene oxide Alkanes, when the temperature rises to the reaction temperature of 120°C, start to pass ethylene oxide stably, continue to feed 97g of ethylene oxide, control the reaction temperature at 120~125°C, control the pressure of the reactor below 0.4MPa, and finish adding epoxy After heating with ethane, heat preservation and aging until the pressure in the reactor no longer drops. Then the temperature drops to about 105°C and starts neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com