Production process of L-ornithine hydrochloride

A kind of technology of ornithine hydrochloride and production process, which is applied in the field of amino acid preparation, can solve the problems of long time, difficult to remove and clean, unfavorable to industrial production, etc., achieve low cost, save production cost, and shorten the length of industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

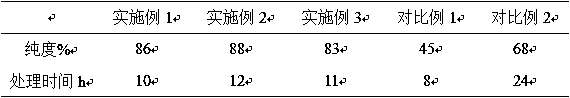

Examples

Embodiment 1

[0025] A production process of L-ornithine hydrochloride, comprising the following steps:

[0026] Step 1, preparation of L-arginine solution: put 2500kg of ultrapure water and 1125kg of L-arginine into the reaction kettle, turn on the stirrer at a speed of 1500r / min, mix well to prepare L-arginine solution, and then add 1mol / L hydrochloric acid to adjust the pH of the L-arginine solution to 8.0~9.0.

[0027] Step 2: Preparation of L-ornithine hydrochloride by enzymatic hydrolysis: Turn on the circulating water, lower the temperature of the L-arginine solution prepared in step 1 to 25°C, and then add 2g / L L-arginine to the reaction kettle Nitase and 225kg of phase transfer catalyst were used for enzymatic hydrolysis to prepare L-ornithine hydrochloride. After 6 hours of reaction, the liquid phase was sampled for detection.

[0028] Step 3, concentration of L-ornithine hydrochloride: filter the qualified solution in step 2 to obtain filtrate and filter residue, store the filte...

Embodiment 2

[0031] A production process of L-ornithine hydrochloride, comprising the following steps:

[0032] Step 1, preparation of L-arginine solution: put 2500kg of ultrapure water and 1000kg of L-arginine into the reactor, turn on the stirrer at a speed of 1500r / min, mix well to prepare L-arginine solution, and then add 0.5mol / L hydrochloric acid to adjust the pH of the L-arginine solution to 8.0~9.0.

[0033] Step 2: Preparation of L-ornithine hydrochloride by enzymatic hydrolysis: Turn on the circulating water, lower the temperature of the L-arginine solution prepared in step 1 to 20°C, and then add 2.5g / L L- Arginase and 100kg of phase transfer catalyst were used for enzymatic hydrolysis to prepare L-ornithine hydrochloride. After 5 hours of reaction, the liquid phase was sampled for detection.

[0034] Step 3, concentration of L-ornithine hydrochloride: filter the qualified solution in step 2 to obtain filtrate and filter residue, store the filter residue in a refrigerator at 4°...

Embodiment 3

[0037] A production process of L-ornithine hydrochloride, comprising the following steps:

[0038] Step 1, preparation of L-arginine solution: put 2500kg of ultrapure water and 1250kg of L-arginine into the reaction kettle, turn on the stirrer at a speed of 3000r / min, mix well to prepare L-arginine solution, and then add 0.75mol / L hydrochloric acid to adjust the pH of the L-arginine solution to 8.0~9.0.

[0039] Step 2: Preparation of L-ornithine hydrochloride by enzymatic hydrolysis: Turn on the circulating water, lower the temperature of the L-arginine solution prepared in step 1 to 22°C, and then add 4g / L L-arginine to the reaction kettle Nitase and 300kg of phase transfer catalyst were used for enzymatic hydrolysis to prepare L-ornithine hydrochloride. After 7 hours of reaction, the liquid phase was sampled for detection.

[0040]Step 3, concentration of L-ornithine hydrochloride: filter the qualified solution in step 2 to obtain filtrate and filter residue, store the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com