Preparation method of high performance modified phenolic resin refrigeration house insulation board

The technology of phenolic resin and thermal insulation board is applied in the field of preparation of high-performance modified phenolic resin cold storage thermal insulation board, which can solve the problems of unsatisfactory thermal insulation effect, poor chemical stability and short service life of phenolic resin thermal insulation board, and achieve good chemical stability compatibility, avoid poor compatibility, and improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

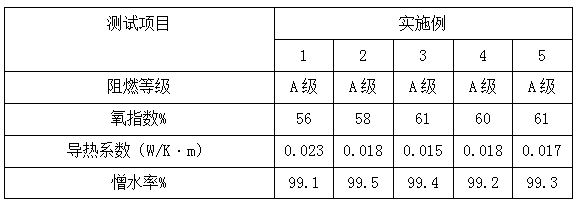

Examples

Embodiment 1

[0021] The preparation method of a kind of high-performance modified phenolic resin cold storage insulation board proposed by the present invention comprises the following steps:

[0022] S1. In parts by weight, weigh 100 parts of phenolic resin, 0.3 parts of melamine cyanuric acid, 3 parts of catmint oil, 0.15 parts of sodium citrate, 5 parts of nano-diatomaceous earth, 3 parts of calendula extract and twelve 0.2 parts of alkyl ethoxy sultaine, heat and dissolve phenolic resin in an appropriate amount of ethanol, add melamine cyanuric acid, catmint oil and dodecyl ethoxy sultaine, stir and mix at 70°C for 2 hours , lower the temperature to 40°C, add sodium citrate, calendula flower extract and nano-diatomaceous earth in turn, continue to stir and mix for 30 minutes, extrude through the screw rod, and pelletize to obtain the modified phenolic resin;

[0023] The calendula extract is prepared by the following method: take 100 parts by weight of calendula after cleaning and dryi...

Embodiment 2

[0028] The preparation method of a kind of high-performance modified phenolic resin cold storage insulation board proposed by the present invention comprises the following steps:

[0029] S1. In parts by weight, weigh 100 parts of phenolic resin, 0.4 part of melamine cyanuric acid, 4 parts of catmint oil, 0.2 part of sodium citrate, 6 parts of nano diatomite, 4 parts of calendula extract and twelve 0.3 parts of alkyl ethoxy sultaine, heat and dissolve phenolic resin in an appropriate amount of ethanol, add melamine cyanuric acid, catmint oil and dodecyl ethoxy sultaine, stir and mix at 70°C for 2 hours , lower the temperature to 45°C, add sodium citrate, calendula flower extract and nano-diatomaceous earth in turn, continue to stir and mix for 25 minutes, extrude through the screw rod, and pelletize to obtain the modified phenolic resin;

[0030] The calendula extract is prepared by the following method: take 100 parts by weight of calendula after cleaning and drying, and extr...

Embodiment 3

[0035] The preparation method of a kind of high-performance modified phenolic resin cold storage insulation board proposed by the present invention comprises the following steps:

[0036] S1. In parts by weight, weigh 100 parts of phenolic resin, 0.45 parts of melamine cyanuric acid, 5 parts of catmint oil, 0.23 parts of sodium citrate, 8 parts of nano-diatomaceous earth, 4 parts of calendula extract and twelve 0.4 part of alkyl ethoxy sultaine, heat and dissolve the phenolic resin in an appropriate amount of ethanol, add melamine cyanuric acid, catmint oil and dodecyl ethoxy sultaine, stir and mix at 75°C for 1.5 h, lower the temperature to 45°C, add sodium citrate, calendula flower extract and nano-diatomaceous earth in sequence, continue to stir and mix for 25 minutes, extrude through the screw rod, and pelletize to obtain the modified phenolic resin;

[0037] The calendula extract is prepared by the following method: take 100 parts by weight of calendula after cleaning and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com