Automatic continuous gas-fueled tea leaf baking machine and control method

A technology for roasting machines and tea leaves, which is applied in the direction of tea processing before extraction, and can solve problems such as gas leakage, accidental flameout, and hidden safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

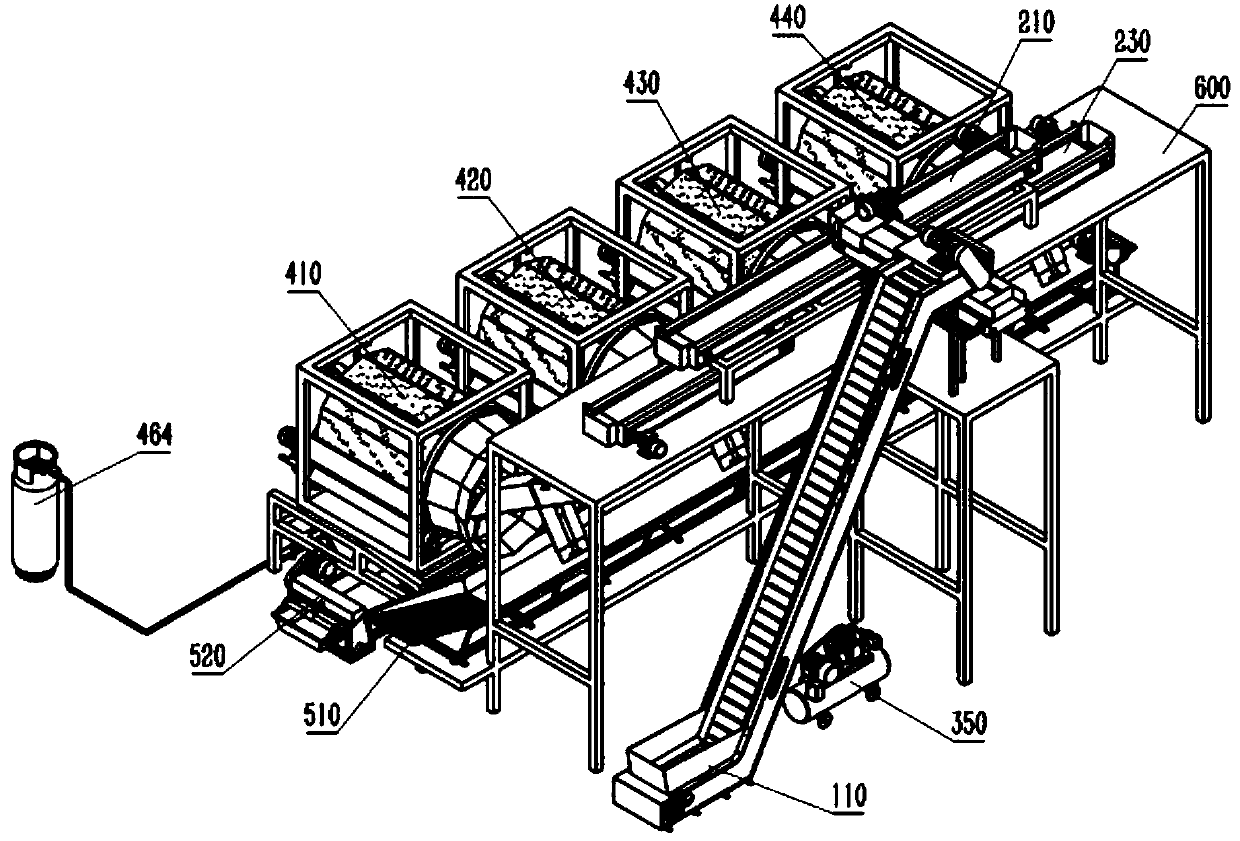

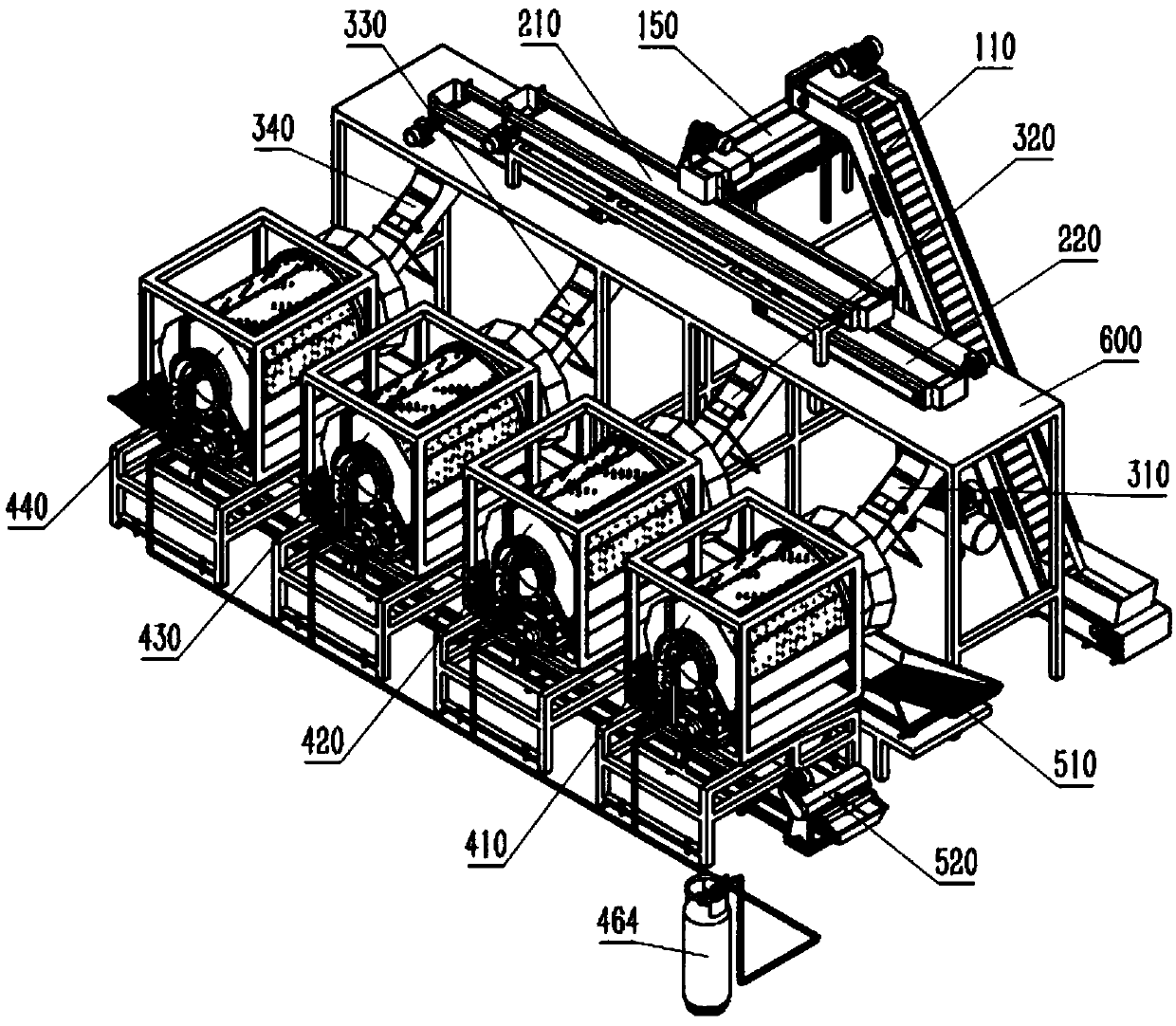

[0054]The automatic continuous gas-fired tea roasting machine of the present invention comprises a PLC control unit, a roasting unit, a feeding unit for automatically quantitatively supplying tea leaves to the roasting unit, and a discharge unit for automatically transporting the roasted tea leaves of the roasting unit to the next process.

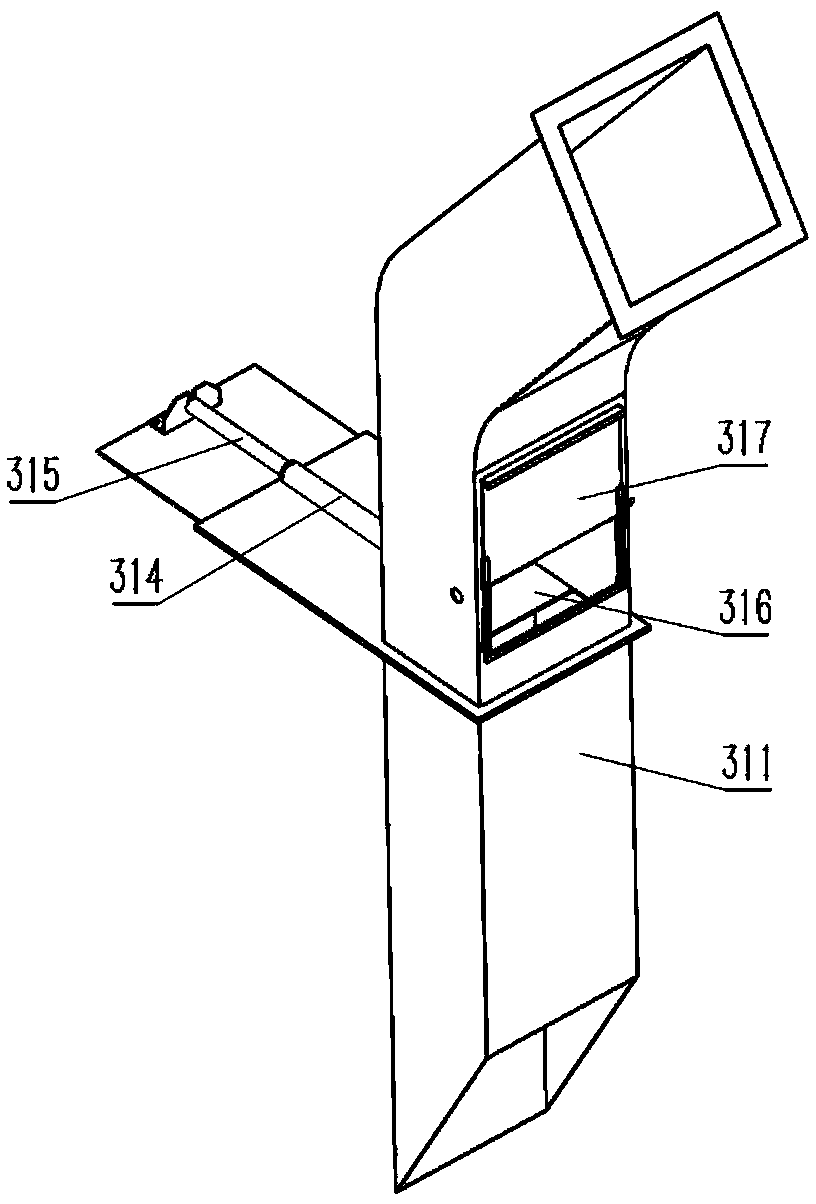

[0055] Such as Figure 5 , 6 , 7, 8, and 12: the baking unit includes a plurality of tea baking sub-machines, the tea baking sub-machines include a baking component, a tea output component and a safety control component; the baking component includes a baking drum 445 and a tea heating unit, The baking drum 445 is installed horizontally, and the side of the baking drum 445 is provided with tea powder sieve holes. The tea heating unit includes a liquefied gas cylinder 464 and a gas-fired heating pipe 450 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com