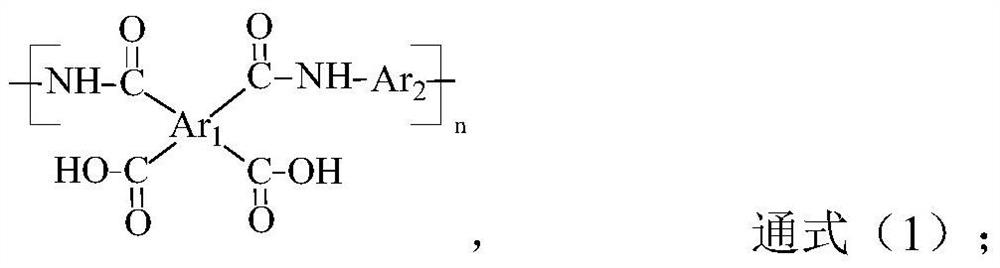

Polyamic acid solution and its preparation method and application

A technology of polyamic acid and solution, which is applied in the direction of single-component synthetic polymer rayon, textiles and papermaking, and fiber chemical characteristics, which can solve the problems of difficult to control product quality decline, narrow molecular weight distribution of polyamic acid solution, and gel particles. Low content and other problems, to achieve the effect of not easy to defect, reduce bad spots and defects, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

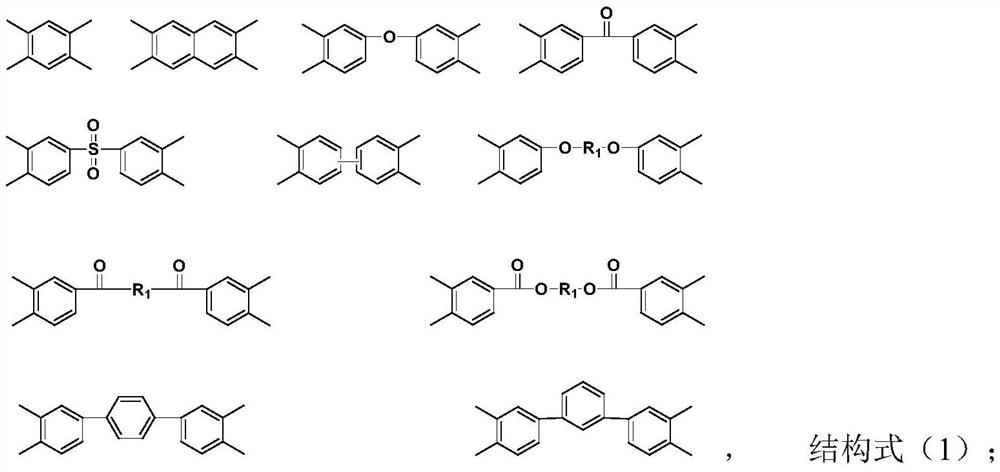

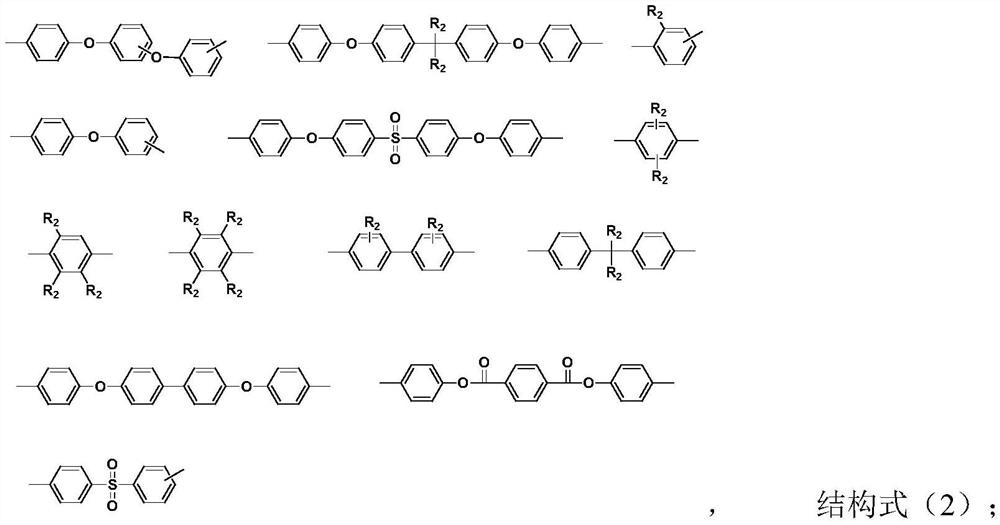

Method used

Image

Examples

Embodiment 1

[0042] Dissolve 23.38g (116.77mmol) of diphenyl ether diamine (ODA) in 273.94g of N,N-dimethylacetamide (DMAc), stir at 25°C, after complete dissolution, add 24.96g (114.43mmol) Perphthalic dianhydride (PMDA), fully reacted to obtain prepolymer solution 1 (dianhydride, diamine molar ratio 0.98, solid content 15%, the same below). Using the same method, 19.41g (96.92mmol) ODA, 289.68g DMAc, and 31.71g (145.38mmol) PMDA were used to prepare prepolymer solution 2 (molar ratio 1.50, solid content 15%). Add 11.36 g of prepolymer solution 2 to prepolymer solution 1 at a rate of 22.0 g / h, and stir thoroughly at 25° C. to obtain a final polyamic acid solution (molar ratio 0.994, solid content 15%). The apparent viscosity of the final solution was measured to be 290 Pa·s, and the molecular weight distribution was 1.44. After passing the solution through a 2 μm glass fiber filter membrane, the filter screen was irradiated by ultraviolet fluorescent lamps without foreign matter.

Embodiment 2

[0044]Dissolve 2002.4g (10mol) ODA in 23089.0g DMAc, stir at 25°C, after complete dissolution, add 2072.1g (9.5mol) PMDA, and obtain prepolymer solution 1 (molar ratio 0.95, solid content 15 %). In the same way, 1001.2 g (5 mol) ODA, 14944.0 g DMAc, and 1635.9 g (7.5 mol) PMDA were used to prepare prepolymer solution 2 (molar ratio 1.50, solid content 15%). 2757.5 g of prepolymer solution 2 was added to prepolymer solution 1 at a rate of 460 g / h, and fully stirred at 25° C. to obtain a final polyamic acid solution (molar ratio 0.99, solid content 15%). The measured apparent viscosity of the final solution was 248 Pa·s, and the molecular weight distribution was 1.42. After passing the solution through a 2 μm glass fiber filter membrane, the filter screen was irradiated by ultraviolet fluorescent lamps without foreign matter.

Embodiment 3

[0046] Dissolve 2002.4g (10mol) ODA in 27837.0g N-methylpyrrolidone (NMP), stir at 0°C, after completely dissolving, add 1090.6g (5mol) PMDA, and obtain prepolymer solution 1 (mol) after fully reacting Ratio 0.5, solid content 10%). In the same way, 1001.2g (5mol) ODA, 28641.6g NMP, and 2181.2g (10mol) PMDA were used to prepare prepolymer solution 2 (molar ratio 2.0, solid content 10%). Add 31,824.0 g of prepolymer solution 2 to prepolymer solution 1 at a rate of 10,000.0 g / h, and stir thoroughly at 0° C. to obtain a final polyamic acid solution (molar ratio 1, solid content 10%). The measured apparent viscosity of the final solution was 168 Pa·s, and the molecular weight distribution was 1.38. After passing the solution through a 2 μm glass fiber filter membrane, the filter screen was irradiated by ultraviolet fluorescent lamps without foreign matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com