Urea-formaldehyde resin waste regeneration modified acrylate interpenetrating network structure polymer emulsion and preparation and curing method thereof

An interpenetrating network structure, acrylate technology, used in coatings and other directions, can solve the problems of poor storage stability, difficult stability of modified polymers, water resistance, alkali resistance, high toughness, etc., to ensure stability. , Improve the use value, the effect of advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] 2. Preparation of recycled urea-formaldehyde resin powder

[0057] After drying the waste urea-formaldehyde resin, use a powder modified high-speed cooling mixing unit (50 liters of Zhangjiagang Hongji Machinery Co., Ltd.) to carry out preliminary stirring and pulverization, so that the largest particle is less than 10 mm, and then put it into a high-speed pulverizer (Hangzhou Xu Public Machinery Equipment Co., Ltd. - multifunctional pulverizer) for pulverization, the particles of solid waste are required to be screened through 120 mesh. Coarse particles continue to be crushed and sieved. The screened particles are urea-formaldehyde resin powder. The gel-like urea-formaldehyde resin can be crushed, and there is no particle size requirement.

Embodiment 1

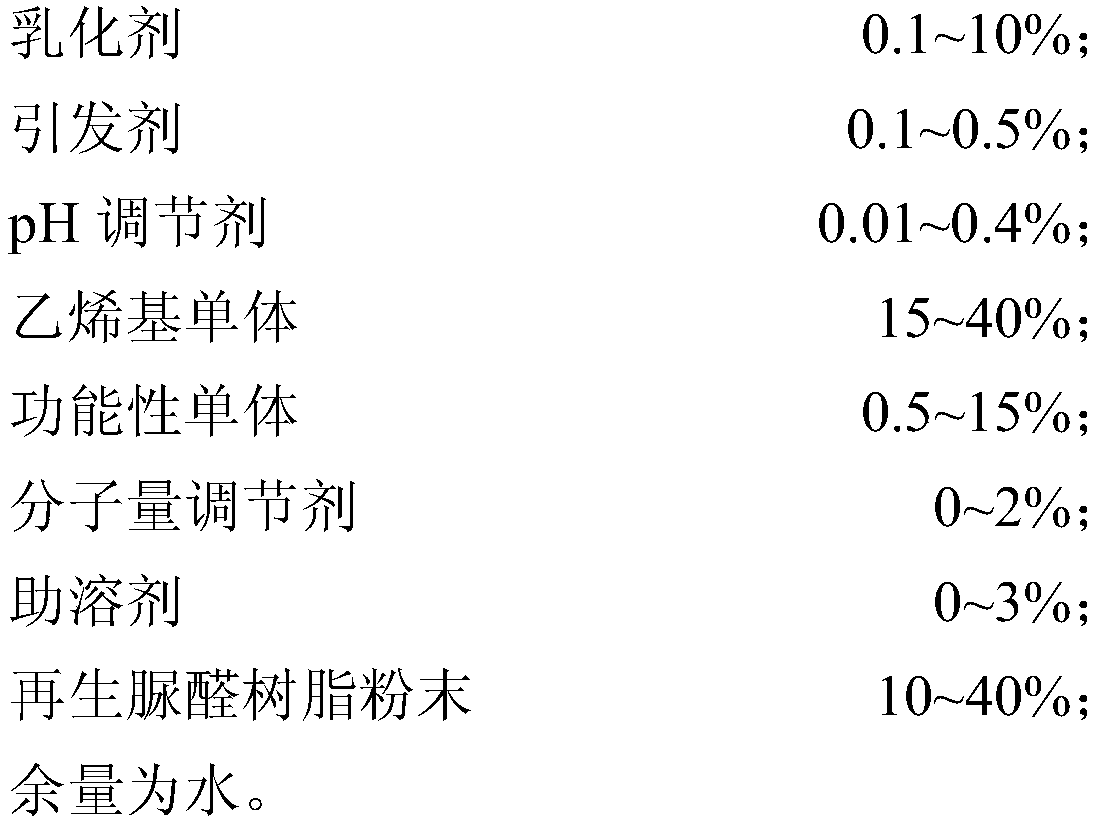

[0059] A kind of regeneration of cross-linked urea-formaldehyde resin and the preparation method of modified acrylate interpenetrating network structure polymer, comprising the following steps:

[0060] 1. Formula (kg):

[0061] a. Pre-emulsion:

[0062] water box:

[0063]

[0064]

[0065] Oil phase:

[0066]

[0067] b. Primer:

[0068]

[0069] c. Additional initiator:

[0070] 10 parts of water;

[0071] APS 0.2 parts.

[0072] 2. Polymerization process

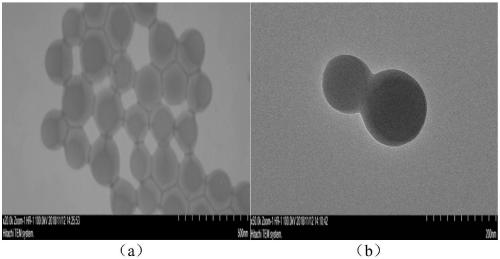

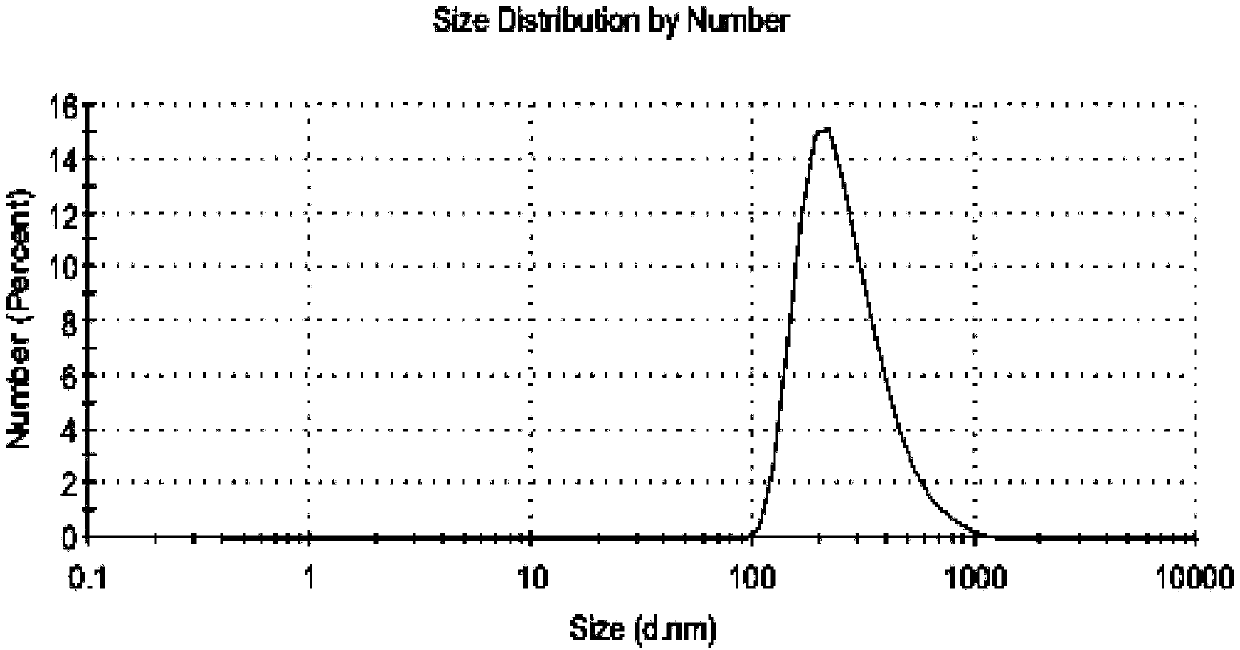

[0073] 1) According to the formulation amount of the pre-emulsion, dissolve the oil-soluble initiator AIBN in the BA monomer and then add other vinyl monomers, then swell the urea-formaldehyde resin powder in this vinyl monomer, and put it in a low-temperature cooling bath In the middle (ice bath), use a high-shear homogeneous emulsifier to shear, disperse, and grind for 60 minutes, shear and disperse the urea-formaldehyde resin particles to translucent or transparent, and then add functional monomers ...

Embodiment 2

[0077] A kind of regeneration of cross-linked urea-formaldehyde resin and the preparation method of modified acrylate interpenetrating network structure polymer, comprising the following steps:

[0078] 1. Formula (kg):

[0079] a. Pre-emulsion:

[0080] water box:

[0081] 100 parts of water;

[0082] Emulsifier NRS-10 5 parts;

[0083] Emulsifier AE3218 12 parts;

[0084] Oil phase:

[0085]

[0086] b. Primer:

[0087]

[0088] c. Additional initiator:

[0089] 10 parts of water;

[0090] APS 0.2 parts.

[0091] 2. Polymerization process

[0092] 1) According to the formulation amount of the pre-emulsion, dissolve the oil-soluble initiator AIBN in the BA monomer and then add other vinyl monomers, then swell the urea-formaldehyde resin powder in this vinyl monomer, and put it in a low-temperature cooling bath In the middle (ice bath), use a high-shear homogeneous emulsifier to shear, disperse, and grind for 60 minutes, shear and disperse the urea-formaldehyde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com